Industries such as automation and robotics use proximity sensors. Without forgetting consumer electronics and safety systems. Proximity sensors are different from mechanical switches.

This is because the object can be detected without physical contact. Hence, reliability and longevity are improved.

They are widely used for position sensing and object counting. Also, for speed detection and safety interlocks.

It is necessary to examine their operating principles and sensing technologies. Then this helps to understand how proximity sensors work. It also requires understanding application-specific behaviors.

This article explains the fundamental working mechanisms of proximity sensors. It explores the major types used in industry. It also highlights their advantages, limitations, and applications.

What is a proximity sensor?

Just like other sensors, a proximity sensor is an electronic device designed to detect an object within a defined range.

It functions without physical contact. It does not rely on mechanical movement. It uses electromagnetic fields or light. Also, on sound waves or capacitance.

These methods allow the sensor to sense objects. When a target enters the sensing zone, the sensor generates an electrical signal. This signal can be used for control, monitoring, or safety purposes.

Proximity sensors are commonly found in industrial automation systems and conveyor lines.

They are also used in machine tools, mobile phones, automotive systems, and building automation.

Their contactless operation makes them ideal for harsh environments. These environments include dust, moisture, vibration, or frequent switching. Such conditions would quickly degrade mechanical sensors.

How Does a Proximity Sensor Work?

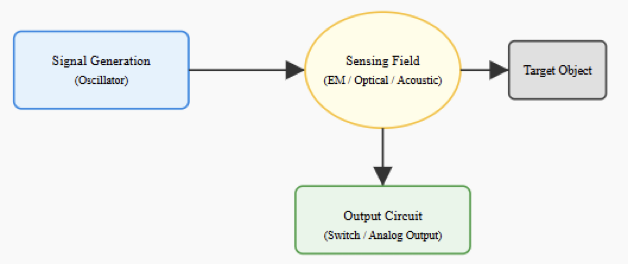

At a fundamental level, all proximity sensors follow the same basic process. First, a sensing field or signal is generated by a sensor. This may be an ultrasonic wave, light beam, or electromagnetic field.

Next, an object enters this field. The object causes a measurable change. This change may be reflection, absorption, disturbance, or attenuation.

Finally, the sensor’s internal electronics detect this change. The change is converted into an electrical output signal.

The nature of the sensing field determines the sensor’s classification. The type of interaction with the object also determines classification. These factors define performance characteristics.

Key Components of a Proximity Sensor

Although designs vary, most proximity sensors include several common internal components.

The sensing element generates and monitors the sensing field. The signal processing circuit amplifies the detected signal. It also conditions the signal.

A comparator or threshold circuit determines significance. It decides whether the change indicates object presence.

Finally, an output stage provides a usable signal. This may be a digital ON/OFF output or an analog signal.

Some proximity sensors include indicator LEDs. They may also include temperature compensation circuits.

Protection features are often included. These include short circuit or reverse polarity protection.

Inductive Proximity Sensors

Working Principle

These sensors are used to detect metallic targets. They operate based on electromagnetic induction.

Inside the sensor, an oscillator generates a high-frequency magnetic field. This field is alternating in nature.

It is produced through a coil at the sensing face. When a metal object enters this field, eddy currents are induced.

These currents form on the surface of the object. The eddy currents create an opposing magnetic field.

This field reduces the amplitude of the original oscillation. The sensor’s electronics monitor this reduction.

The sensor switches its output state once the oscillation drops below a predefined threshold.

The following figure illustrates an inductive proximity sensor showing coil and magnetic field lines. Also, it indicates a metal target and eddy current formation.

Characteristics

Inductive sensors are highly reliable. They are immune to dirt, oil, water, and non-metallic materials. However, their sensing range is relatively short. The range depends on the type of metal.

Ferromagnetic materials such as steel are detected at longer distances. Non-ferrous metals include aluminum or copper. These are detected at shorter distances.

Capacitive Proximity Sensors

Working Principle

Through measuring changes in capacitance, objects are detected by these sensors. The sensor consists of a sensing electrode.

It also includes a reference electrode. Together, they form a capacitor. The surrounding environment acts as the dielectric medium.

When an object approaches the sensing face, it alters the dielectric constant. This occurs within the sensing field.

The change increases the capacitance. The sensor’s internal oscillator detects this change. The processing circuit evaluates it. If capacitance exceeds the preset limit, the sensor output changes.

Characteristics

Capacitive sensors can detect metallic objects. They can also detect non-metallic objects. These include liquids, plastics, powders, and grains. They are commonly used for level detection.

This occurs in tanks and silos. However, environmental factors are a challenge to them. These include humidity and dust, without forgetting temperature changes. Finally, periodic recalibration is also necessary.

Photoelectric Proximity Sensors

Working Principle

Photoelectric sensors use light to detect objects, which is typically infrared or visible. A light emitter sends a beam toward a target area. A receiver detects the light. The presence of an object alters the received light.

This occurs through interruption, reflection, or diffusion. There are three main photoelectric sensing modes.

In through-beam mode, the object blocks the light. The light travels between a separate emitter and receiver.

In retro-reflective mode, light reflects off a reflector. It returns to the sensor unless interrupted by an object.

In diffuse mode, the object itself reflects light. The light is reflected back to the receiver.

Characteristics

Photoelectric sensors offer longer sensing distances. These distances exceed those of inductive and capacitive types. They can detect very small objects.

They work with a wide range of materials. However, performance can be affected by dust. Ambient light can also affect performance. Surface reflectivity of the target is another factor.

Ultrasonic Proximity Sensors

Working Principle

These sensors operate using high-frequency sound waves. Human hearing is far beyond these waves.

Initially the sensor uses its transmitter to emit an ultrasonic pulse. It then waits for the echo. The echo is reflected by an object.

The time delay is measured. This delay occurs between transmission and reception. It is converted into distance.

The conversion uses the speed of sound. The sensor output is activated when the measured distance falls within a preset range.

This time-of-flight principle allows accurate distance measurement. It works regardless of object color. It also works regardless of object transparency.

Characteristics

When it comes to detecting transparent objects, then ultrasonic sensors are the choice. Examples include glass or clear plastic.

These objects are challenging for optical sensors. Ultrasonic sensors are widely used for level measurement.

However, air temperature can affect sound propagation. Not only turbulence but also humidity has influence to accuracy.

Magnetic Proximity Sensors

Working Principle

Magnetic proximity sensors detect magnetic fields. These fields are generated by permanent magnets or electromagnets. Common implementations include reed switches. Hall-effect sensors are also used.

When a magnetic field approaches the sensor, it causes a change. This change occurs in electrical behavior. It may close a reed contact. It may also alter the voltage output of a Hall-effect element.

Characteristics

Magnetic sensors are simple and robust. They are well suited for position detection. Common uses include doors, cylinders, and rotating machinery.

Their operation depends on the presence of a magnet. This requirement may limit some applications.

Output Types and Signal Processing

Proximity sensors typically provide digital outputs. They may also provide analog outputs. Digital outputs indicate a simple ON or OFF state. This occurs when an object is detected. Analog outputs provide a continuous signal.

The signal is proportional to distance or signal strength. Common output configurations include NPN and PNP. Normally open and normally closed outputs are also used.

Signal processing ensures noise immunity. It provides stable switching. It ensures repeatable performance. This is important in electrically noisy industrial environments.

Advantages of Proximity Sensors

One primary advantage of proximity sensors is non-contact operation. This eliminates mechanical wear. They offer fast response times.

They also provide high repeatability. Long service life is another benefit. Proximity sensors improve safety.

They enable contactless detection. This is useful in hazardous areas. Their versatility allows use across many industries.

These include manufacturing and packaging. Automotive and consumer electronics are also included.

Limitations and Selection Considerations

Each sensing technology has constraints. These relate to range and material compatibility. Environmental sensitivity is also a factor. Proper selection requires careful consideration.

Target material must be evaluated. Sensing distance is important. Mounting conditions must be considered. Temperature range and output type are also critical.

Understanding the working principle helps engineers choose correctly. It allows selection of the most suitable sensor. This ensures proper application performance.

Industrial and Everyday Applications

In industrial automation, proximity sensors are used for object counting. They are also used for position detection.

Speed monitoring is another application. Machine safety is equally important. In robotics, they assist with obstacle detection.

They also support accurate positioning. In consumer electronics, they enable screen wake-up features. Touchless controls are also supported. Automotive systems rely on proximity sensors.

They are used for parking assistance. Door detection is another use. Engine position sensing is also common.

Their widespread use highlights their importance. They are essential in modern technology.

Key Takeaways: How Does a Proximity Sensor Work

The present article detailed the fundamental working mechanisms of proximity sensors. It studied the major types used in industry. It also showed their advantages, limitations, and applications.

From the afore mentioned we can say that proximity sensors play a vital role in modern systems. They enable reliable and contactless detection.

They generate a sensing field. They detect how objects interact with it. These sensors convert physical presence into electrical signals.

Different types exist. These include inductive and capacitive. Plus, photoelectric, ultrasonic, and magnetic sensors.

Each uses distinct physical principles. Understanding how proximity sensors work allows effective selection.

It also supports correct application and maintenance. As automation continues to evolve, proximity sensors remain fundamental. They are key building blocks in sensing technology.

FAQ: How Does a Proximity Sensor Work

What is a proximity sensor?

A proximity sensor is a device that detects the presence or absence of an object without physical contact. It constantly emits a field or signal and senses changes caused by nearby objects.

How does a proximity sensor detect objects?

It emits a signal (magnetic field, electric field, light, or sound) and monitors changes in that signal when an object enters its detection range.

What kinds of signals do proximity sensors use?

Different types use electromagnetic fields (inductive), electric fields (capacitive), infrared/visible light (photoelectric), or sound waves (ultrasonic) to detect objects.

Do proximity sensors need physical contact to work?

No, they detect objects without touching them, which reduces wear and increases lifespan.

Can proximity sensors detect all types of materials?

It depends on the type:

- Inductive: best for metal.

- Capacitive: can sense metal and non-metal like plastic or liquid.

- Ultrasonic and photoelectric: can detect a wide range of materials.