Both Modbus RTU and Modbus TCP are widely used and essential industrial communication protocols.

They play a critical role in connecting controllers, sensors, actuators, and monitoring systems in automation.

Even though both originate from the same Modbus standard, they operate in different ways because of their distinct transport layers.

Modbus RTU uses a serial connection, typically implemented with RS-485 or RS-232 physical layers.

By contrast, Modbus TCP uses Ethernet technology and runs on top of the TCP/IP stack.

The internal message structure of Modbus remains consistent across both protocols.

But the way the message is packaged, transported, and managed is what makes them different.

This article shows the difference between Modbus RTU and TCP. It details characteristics of each one, installation and it compares which one the best.

What is the Difference between Modbus RTU and Modbus TCP?

Here are the difference between Modbus RTU and Modbus TCP.

Communication medium

Modbus RTU

This version communicates over serial connections. It usually relies on RS-485 or RS-232 physical layers.

RS-485 is more popular because it supports longer distances, up to about 1200 meters, and can resist electrical noise better than RS-232. RS-232 is simpler but limited in distance, typically below 15 meters.

In noisy industrial environments with motors and drives, RS-485 is the preferred choice.

Modbus TCP

This version runs over Ethernet networks. It uses the TCP/IP protocol stack to move messages across devices.

Data is transported through common networking hardware such as switches, routers, and network interface cards.

This allows Modbus TCP devices to share the same infrastructure used for office networks, supervisory systems, or even cloud connections.

Network topology

Modbus RTU

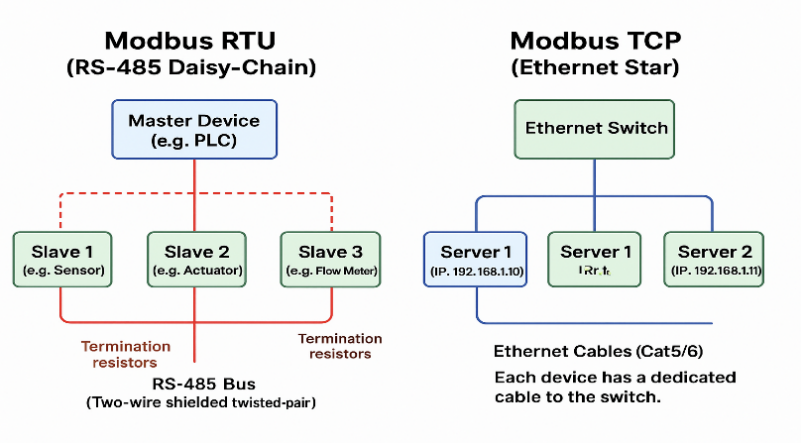

It usually adopts a multi-drop or “daisy-chain” topology. In this setup, a single master communicates sequentially with multiple slave devices that are linked in a line.

Each device has a connection to the next one, forming a chain. The master initiates all communication, and only the addressed slave responds.

This arrangement is simple but sensitive to wiring problems because one loose connection can affect all devices downstream.

Modbus TCP

It typically uses a star topology. Every device connects to a central switch or router using Ethernet cables. This is the same design used in most office and home networks.

It is more resilient than daisy-chaining because the failure of one cable affects only one device, not the entire system.

Addressing mechanism

Modbus RTU

Devices are identified by a unique numerical slave address ranging from 1 to 247. The master includes the address in its request, and only the matching slave replies.

This makes addressing straightforward but limited in size.

Modbus TCP

Devices are primarily identified by their IP address and port number, just like any computer on a network.

The Modbus message still carries a “Unit Identifier” field, which acts like the slave ID.

This is particularly useful when passing through a gateway that links Modbus TCP to Modbus RTU devices.

Message encapsulation

Modbus RTU

The message includes several fields: the slave address, function code, data, and a Cyclic Redundancy Check (CRC) for error detection.

The beginning and end of the frame are not marked by characters but instead by silent intervals on the line.

Timing is therefore critical. If silence between bytes is too long, devices may treat it as the end of the frame.

Modbus TCP

Here, the Modbus message is encapsulated inside a TCP/IP packet. An additional 7-byte header, known as the Modbus Application Protocol (MBAP) header, is added in front of the actual Modbus data.

This header provides transaction identifiers and length information, making communication more flexible.

Error checking

Modbus RTU

A 16-bit CRC checksum is used for error detection. This checksum is computed from the message and appended to the frame.

At the receiver, the CRC is recalculated. If it does not match, the message is discarded. This makes Modbus RTU reliable on noisy serial lines.

Modbus TCP

Instead of adding its own CRC, it relies on the built-in error-checking of the TCP/IP protocol stack. TCP ensures packet delivery, correct order, and integrity.

Since Ethernet already provides its own error detection mechanisms, adding a CRC at the Modbus level would be redundant.

Speed and performance

Modbus RTU

The speed is limited by the baud rate of the serial line. Common baud rates are 9600, 19200, and up to 115200 bps.

This is sufficient for slow processes like temperature monitoring or motor control but not for high-speed data acquisition.

Modbus TCP

Ethernet offers much higher speeds, typically 10 Mbps, 100 Mbps, or even 1 Gbps. Multiple clients can communicate with servers simultaneously.

This makes Modbus TCP suitable for SCADA systems where rapid updates and high volumes of data are essential.

Scalability

Modbus RTU

RS-485 networks are limited to about 32 devices per segment. Repeaters can extend this to 128 or more, but expansion is not endless. Long cable lengths and increased devices may introduce signal degradation.

Modbus TCP

Ethernet networks scale much more easily. The number of devices is limited mainly by the available IP addresses and network hardware. Hundreds or thousands of devices can coexist in the same network.

Multi-master Support

Modbus RTU

It follows a strict master-slave model. Only the master initiates communication.

While multiple masters can exist, implementing them requires special arbitration schemes to avoid conflicts on the serial bus. This adds complexity.

Modbus TCP

It adopts a client-server architecture. Multiple clients can send requests to multiple servers at the same time. The TCP/IP stack handles arbitration, avoiding collisions automatically.

Security

Modbus RTU

Security is minimal. It does not include authentication or encryption. Protection is mostly physical, achieved by isolating the serial network from unauthorized access.

Modbus TCP

It is more exposed since it operates on IP networks, which can be accessed remotely.

Without safeguards, it is vulnerable to attacks. However, security can be reinforced by using VPNs, firewalls, access controls, or modern secure versions like Modbus over TLS.

Cost

Modbus RTU

The required hardware is inexpensive. Serial converters, RS-485 cables, and connectors are cheap. For small systems with a limited number of nodes, this is very cost-effective.

Modbus TCP

Ethernet equipment such as managed switches, industrial routers, and special network cards may cost more.

However, many plants already have Ethernet infrastructure, so integrating Modbus TCP can reduce installation costs in the long run.

Wiring and installation

Modbus RTU

Careful wiring practices are necessary. Proper termination resistors at the ends of RS-485 lines are required to prevent reflections.

Shielding and grounding are also important to minimize noise interference. Troubleshooting often requires checking continuity, terminations, and polarity.

Modbus TCP

Installation is simpler for IT-trained personnel. Standard Ethernet cables and RJ45 connectors are widely available.

Troubleshooting is often easier because diagnostic tools such as ping, Wireshark, and SNMP monitoring can be used.

Ideal use cases

Modbus RTU

Best for small, localized systems. It is suitable when speed is less important, cost is critical, and only a few devices are needed.

It remains common in legacy systems, simple monitoring tasks, and isolated industrial processes.

Modbus TCP

More suitable for modern and large-scale networks. It is ideal where fast communication, remote access, and integration with advanced SCADA systems are required.

It supports Industry 4.0 applications and remote diagnostics.

Conclusion

Modbus RTU and Modbus TCP both originate from the same core Modbus protocol, but their implementations diverge significantly.

Modbus RTU is the older, serial-based option. It is simple, robust, and cost-effective for small systems.

It remains valuable where legacy equipment is present or where low cost is a primary concern.

Modbus TCP, in contrast, is the modern Ethernet-based version. It offers higher speed, better scalability, multi-client support, and easy integration with advanced automation systems. It is future-oriented and aligns with digital transformation in industry.

The choice between the two depends on a careful evaluation of application requirements. For local, low-cost, noise-resistant connections, Modbus RTU remains strong.

For scalable, high-performance, and interconnected systems, Modbus TCP is the clear choice.

Both protocols continue to coexist in industry, often connected through gateways, ensuring backward compatibility while enabling progress toward modern networking.

FAQ: Difference between Modbus RTU and Modbus TCP

What are Modbus RTU and Modbus TCP?

Modbus RTU is a serial communication protocol that runs over physical links like RS-485 or RS-232; Modbus TCP (also called Modbus TCP/IP) is the Modbus protocol wrapped in Ethernet / TCP/IP, so it works over standard network connections.

Which environments are each suited for?

Modbus RTU is best for simpler, localized networks. If devices are close, cost matters, or there’s existing serial infrastructure, RTU often wins; Modbus TCP is better for larger, distributed networks, or when integration with modern networks or remote access is needed.

Can RTU and TCP communicate with each other?

Yes. Gateways or converters exist that translate between Modbus RTU and Modbus TCP. This lets you mix legacy RTU devices with newer TCP-based systems.

What are the differences in data encoding and error checking?

Modbus RTU uses binary (compact) encoding and includes a CRC (Cyclic Redundancy Check) for error detection; Modbus TCP doesn’t include its own CRC in the Modbus frame because it relies on TCP/IP’s error-checking (checksums, retransmissions).

How do speed and latency compare?

Modbus RTU is limited by the serial link’s baud rate (commonly up to 115,200 bps) and by physical constraints.

This introduces more latency when many devices are in a daisy-chain; Modbus TCP enjoys much higher throughput via Ethernet (e.g., 100 Mbps, Gigabit), supports multiple simultaneous connections, and tends to have lower latency in that environment.

What are the physical and wiring differences?

RTU uses serial cabling (twisted pair for RS-485, etc.), may require termination resistors, care with grounding, and is more sensitive to cable length and electromagnetic noise; TCP uses Ethernet (CAT5, CAT6, etc.), standard network hardware (switches, routers), and is less sensitive to issues like signal reflections over long wires (within Ethernet’s limits).

What about scalability and number of devices?

RTU networks are more limited: number of slaves, distance, and physical signal quality are constraints; TCP networks scale more easily.

IP addressing allows many devices; network infrastructure (switches, routers) can be expanded.

Cost implications?

RTU hardware is often cheaper per device and simpler wiring can reduce costs in smaller systems.

However, costs can rise if long cable runs, repeaters, or special shielding are required; TCP infrastructure requires Ethernet-capable devices, switches, possibly more capable processors, but existing network infrastructure can reduce costs, especially when scaling.

Is security different between the two?

RTU is more “hidden” because of its physical nature (serial lines). There is less exposure to network attacks.

But it has minimal to no built-in encryption or authentication. Physical security matters; TCP is exposed to networked threats (if connected or accessible via larger networks or the internet).

To secure Modbus TCP, you should use network segmentation, firewalls, possibly VPNs, and keep devices updated.

What are typical pitfalls or challenges?

For RTU: signal integrity over long runs; timing issues in serial frames; one master only (in many implementations); dealing with noise and wiring issues; For TCP: overhead from network layers; managing IP addressing; needing Ethernet capable hardware; vulnerability if insecurely exposed to larger networks; possible latencies or congestion in busy networks.

Which protocol gives better reliability?

It depends. RTU can be very reliable in well-designed environments (short runs, good wiring, clean power). But error detection is simpler (CRC, etc.); TCP offers reliability at the transport layer (TCP guarantees delivery, re-ordering, etc.).

But reliability depends also on network infrastructure (switches, routers) and how well those are managed.

When is one clearly preferred over the other?

Choose Modbus RTU when cost, legacy compatibility, simplicity, and local/short-distance applications are primary; Choose Modbus TCP when speed, scalability, remote access, integration with modern networks, or future growth are important.