Process Field Bus, also known as Profibus, is one of the standardized industrial communication protocols.

In this case, it is designed for fast, reliable data exchange between controllers and sensors. Also, with actuators and the rest of the automation devices.

Profibus was developed in Germany in the late 1980s. Then it quickly became one of the most widely adopted fieldbus systems worldwide.

It enables real-time communication in industrial networks. This improves operational efficiency, process reliability, and plant safety.

Profibus reduces wiring complexity in industrial systems. It enhances diagnostics and fault detection capabilities. It also allows interoperability among devices from multiple manufacturers.

Its flexibility makes it suitable for both discrete manufacturing and continuous process industries.

This article reviews Profibus, its architecture, communication principles, variants, physical layer, applications, advantages, limitations, and comparisons with other industrial protocols.

What is Profibus?

Profibus is a digital fieldbus protocol that allows multiple devices to communicate over a shared communication medium.

It operates using master–slave or multi-master configurations, depending on system requirements.

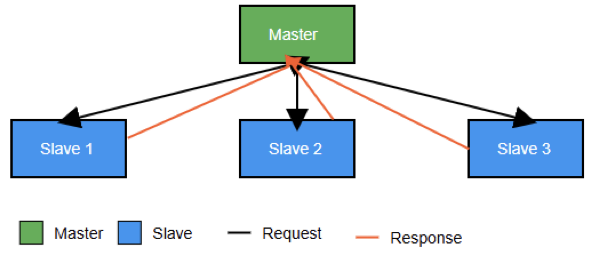

In a master–slave arrangement, the master device is typically a programmable logic controller (PLC). The master controls communication by sending requests. Slave devices respond with data.

This structured approach ensures deterministic and predictable data exchange. Communication occurs within defined time limits.

This is essential for time-critical industrial control applications. Profibus supports cyclic real-time data transfer as well as acyclic communication for configuration and diagnostics.

Key Features of Profibus

One of the most important features of Profibus is deterministic communication. Data exchange occurs within fixed time intervals.

These intervals are predictable and repeatable. This ensures consistent system response and stable control behavior. This determinism makes Profibus suitable for applications requiring precise timing.

The rate of 12 Mbps is the maximum speed used by Profibus DP for data exchange. This allows fast cyclic communication.

Data is exchanged efficiently between controllers and field devices. This capability allows efficient control of machines, drives, and distributed I/O systems.

The protocol supports both master–slave and multi-master operation. Coexistence between multiple masters on the same network is possible.

This enables system redundancy. It improves availability in complex automation systems.

Profibus includes several protocol variants, including FMS, PA, and DP. Each variant is optimized for different industrial needs. These range from high-speed discrete automation to intrinsically safe process control.

Profibus is an internationally standardized protocol under IEC 61158. Interoperability can be ensured by this standardization.

Devices from different manufacturers can communicate reliably. This standardization reduces vendor lock-in. It also simplifies system integration.

Profibus significantly reduces wiring complexity. It replaces multiple point-to-point connections with a single bus cable.

This lowers installation costs and simplifies maintenance. Without forgetting, it improves system scalability.

Profibus supports flexible network topologies. These include line, tree, and star configurations.

This flexibility allows networks to adapt to different plant layouts.

It also supports future expansion requirements.

The protocol supports multiple physical layers. These include RS-485, Manchester Bus Powered (MBP), and fiber optics. Reliable performance is achieved in challenging and hazardous industrial conditions.

Profibus PA supports intrinsic safety. This enables safe operation in explosive process environments. Advanced diagnostic functions are provided.

Alarm mechanisms support early fault detection. They improve system uptime and streamline troubleshooting processes.

Types of Profibus

Profibus: Decentralized Peripherals

Shortly known as Profibus DP. This variant is the most widely used. Its primary application lies in discrete manufacturing and machine automation. It enables fast cyclic data exchange.

Communication occurs between controllers and field devices. Connected devices include sensors, actuators, and drives. Remote I/O modules are also supported. Update times can be as low as 1.5 ms.

This performance suits fast industrial processes. Typical applications include assembly lines, robotics, and conveyors.

Profibus: Process Automation

Also known as Profibus PA, it is designed for process industries. Common applications include chemicals, oil and gas, and pharmaceuticals.

It uses Manchester Bus Powered technology. In this, power and data share the same two-wire cable.

This simplifies wiring and supports intrinsic safety, making PA suitable for hazardous areas. PA devices typically include transmitters, valves, and analyzers installed in the field.

Profibus: Fieldbus Message Specification

Shortly known as Profibus FMS. It supports complex communication and messaging between controllers and intelligent devices.

Although it is less commonly used today due to the dominance of DP and PA, FMS is still found in some legacy systems requiring advanced device-to-device communication.

Profibus Communication Principle

Profibus operates on a deterministic communication principle that ensures data exchange occurs within predefined time limits. Bus access is carefully controlled to prevent collisions and data loss.

Depending on network design, Profibus can operate using master–slave or multi-master communication.

In master–slave communication, the master initiates all data exchange by polling slave devices in a cyclic sequence.

Slaves respond only when addressed. This approach ensures predictable communication behavior.

It is widely used in Profibus DP systems. In multi-master networks, multiple masters share the same bus.

A token-passing mechanism controls bus access. Only one master communicates at a time.

The token circulates among masters in a predefined order. This ensures fair communication and improves reliability and redundancy.

Profibus supports cyclic data for real-time control. Acyclic data is used for configuration and diagnostics. Alarm data is applied for fault reporting.

This combination supports efficient operation and maintenance. Monitoring occurs without disrupting real-time control.

Device Addressing and Configuration

Each Profibus device requires a unique address. This can be configured using hardware switches or software tools. Network configuration includes setting addresses and transmission speeds.

It also involves defining cyclic data parameters and diagnostic options. GSD files describe device capabilities. They ensure compatibility during system integration.

Profibus Network Topology

Profibus supports three types of topologies: first line, second tree, and third star topologies

- Line topology: Most common and cost-effective, using a daisy-chain connection.

- Tree topology: Introduces branches for large or distributed systems.

- Star topology: Uses active couplers to improve fault isolation and reliability.

Applications of Profibus

Profibus is widely used in manufacturing and process industries. It is also applied in building automation and the energy sector.

- Energy sector: Profibus is used in renewable energy installations, substations, and power plants.

- Building automation: Combining HVAC and lighting. Also, safety systems are considered.

- Manufacturing: Dealing with high-speed machine control and robotics.

- Process industries: In hazardous areas, field instruments are connected by Profibus PA.

Advantages and Disadvantages of Profibus

Profibus offers numerous advantages that make it a widely used industrial communication protocol. One key benefit is high-speed communication. This ensures timely control of devices in real-time applications.

Next is determinism, providing predictable response times. This is essential for critical control systems. Profibus also reduces wiring complexity. Since it is a single bus, it can replace multiple point-to-point connections.

This simplifies installation and maintenance. The protocol ensures the properties of interoperability.

It allows communication between devices from different manufacturers. In addition, advanced diagnostics provide real-time error detection. These characteristic aids to improve system reliability and reducing downtime.

The latter helps to reduce downtime and streamline maintenance efforts. Profibus PA supports intrinsic safety.

Provides suitability for operation in hazardous areas. Finally, the system is highly scalable. Gives the ability to serve both small machines and large process plants effectively.

On the other hand, despite these advantages, Profibus has several limitations. Limited bandwidth is one of the major drawbacks.

The maximum data rates are 12 Mbps, which is slower than modern Ethernet. Also, it may be insufficient for high-data applications.

The data limit per node in Profibus DP is relatively low, around 244 bytes. The master-slave design may limit systems that need direct peer-to-peer communication.

Integration with IT systems is more limited than with Ethernet-based protocols such as PROFINET.

Hardware and installation costs can also be high. Due to specialized components such as ASICs, connectors, repeaters, and cables.

Finally, cable length limitations are especially problematic at higher speeds. It may require repeaters, adding complexity and cost to network design.

Profibus vs Other Industrial Protocols

Modbus

Compared to Modbus, Profibus provides faster communication. It also ensures deterministic operation suitable for real-time control. Modbus is simpler and used mainly for monitoring.

Ethernet/IP

Compared to Ethernet/IP, Profibus offers predictable timing. However, it has lower bandwidth and less IT integration.

It is well-suited for deterministic industrial control.

On the other hand, Ethernet/IP excels in high-speed data transfer and provides superior network connectivity.

Profinet

Gaining popularity is a trend of Profinet and other Ethernet-based technologies. Despite this, Profibus remains common in many legacy systems. It provides robust and deterministic communication where reliability is critical.

CANopen

Compared to CANopen, Profibus supports larger networks. It also supports longer communication distances. This makes it more suitable for factory and process automation.

Profibus provides advanced diagnostics for easier maintenance. It delivers higher data throughput and better integration with industrial controllers. These features improve overall system performance.

Key Takeaways: What is Profibus?

Profibus is a proven industrial communication protocol. This is because it is highly reliable.

It has played a major role in developing modern automation systems. Its variants include DP, PA, and FMS.

They address a wide range of industrial requirements. Applications range from high-speed machine control to intrinsically safe process automation.

Profibus provides deterministic communication. It offers a flexible network design.

Advanced diagnostics enhance system reliability.

Strong standardization supports efficient industrial operations. Industrial Ethernet has grown rapidly. Despite this, Profibus remains important in many existing installations. It continues to demonstrate value in demanding industrial environments.

FAQ: What is Profibus?

What is Profibus?

A digital industrial communication protocol connecting controllers and field devices.

Why is it used?

It ensures reliable data exchange and reduces wiring complexity.

Main versions?

Profibus DP, PA, and FMS.

How does it communicate?

Master polls slaves in a cyclic process; slaves respond.

Difference from Profinet?

Profibus is serial and deterministic; Profinet is Ethernet-based with higher bandwidth.

Is it still used?

Yes, especially in legacy systems requiring reliable timing.

Is it standardized?

Yes, under IEC 61158.

Physical media?

RS-485, MBP cabling, and fiber optics.