A proximity sensor is a device designed to detect the presence or absence of nearby objects without the need for direct physical contact.

In other words, it can “sense” objects within a certain distance, even if it does not touch them.

This makes it a key element in modern industrial automation systems, where efficiency and durability are critical.

These sensors play a central role in detecting when an object is within their detection zone.

Depending on the technology used, they may rely on electromagnetic fields, ultrasonic sound waves, or light beamsto identify an object. Since the process is contactless, there is less wear and tear on mechanical parts.

This means longer machine life, less frequent downtime, and reliable object detection.

This article talks about proximity sensors. It details about how they work, applications, varieties, challenges and limitations, and finally, their future.

How Proximity Sensors Work

Proximity sensors function by monitoring changes in their environment. When a target object enters the sensing zone, the internal circuit of the sensor detects this change.

The sensor then generates an output signal, which can be digital (on/off) or analog (distance-related).

The exact working principle depends on the sensor type. For instance, an inductive sensor looks for changes in electromagnetic fields, while an ultrasonic sensor measures the time delay of sound waves returning.

In all cases, the sensor acts as a bridge between the physical world and automation systems, ensuring that machines know what is happening around them in real time.

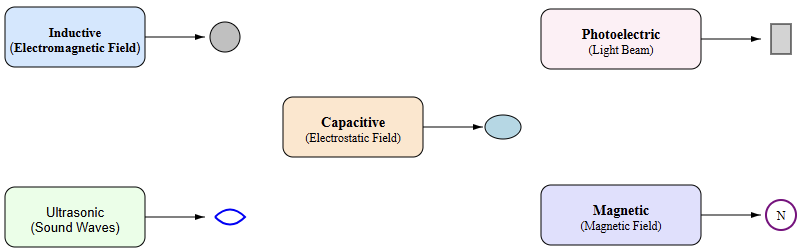

Types of Proximity Sensors

Inductive Proximity Sensors

Principle

They generate an electromagnetic field. When a metallic object enters this field, it changes the inductance. The sensor detects this disturbance and produces an output signal.

Target material

Only metals (iron, steel, aluminum, copper).

Applications

Widely used in manufacturing plants to detect metallic parts on conveyors, in robotics for arm positioning, and in welding stations where heat and sparks make other sensors unreliable.

Advantages

Very robust and dependable. They resist dirt, oil, and moisture. They keep working in harsh environments.

Limitations

Cannot detect non-metallic materials such as wood, plastic, or liquids. Their detection range is short (usually a few millimeters).

Capacitive Proximity Sensors

Principle

They create an electrostatic field. When an object enters, it alters the capacitance of the system. The sensor detects this variation.

Target material

Detects metallic and non-metallic substances. Suitable for plastics, powders, grains, liquids, and even glass.

Applications

Used in liquid-level monitoring (tank sensors), packaging machines, and quality checks where detection of non-metallic substances is crucial.

Advantages

Very versatile. Can detect objects even when hidden behind thin non-metallic walls (like a plastic tank).

Limitations

Sensitive to humidity, temperature, and dust. Range is also limited compared to ultrasonic or photoelectric sensors.

Ultrasonic Proximity Sensors

Principle

Emit ultrasonic sound waves (above human hearing). Measure the time taken for sound to travel to the object and bounce back.

Target material

Can detect any material, regardless of shape, color, or transparency.

Applications

Used for liquid-level measurement, obstacle detection in robotics, parking sensors in vehicles, and material height detection.

Advantages

Longer detection ranges (up to several meters). Unaffected by dust, dirt, or surface color.

Limitations

Sensitive to temperature changes and air pressure variations. Have a blind zone directly in front of the sensor.

Photoelectric Proximity Sensors

Principle

Rely on light beams (infrared or laser). Detection happens when the beam is interrupted or reflected by an object.

Target material

Wide range of materials including transparent items like glass or thin plastic.

Types

- Through-beam: Transmitter and receiver are separate. The object blocks the beam.

- Retro-reflective: Uses a reflector opposite the sensor. The object breaks the reflected beam.

- Diffuse: The sensor detects the light reflected by the object itself.

Applications

Counting objects on conveyors, detecting misaligned labels, ensuring packaging quality.

Advantages

Long sensing ranges and fast detection speed.

Limitations

Can be disrupted by dust, dirt, or ambient light interference. Requires clear line of sight.

Magnetic Proximity Sensors

Principle

Use a magnetic field to detect magnets or magnetic objects.

Target material

Only magnetic materials or magnets.

Applications

Used in door security locks, cylinder position sensing in pneumatic/hydraulic systems, and safety interlocks.

Advantages

Can detect objects even through non-magnetic barriers like plastic, wood, or thin metal sheets.

Limitations

Useless for non-magnetic objects.

Applications in Automation

Proximity sensors are indispensable in industrial automation. They support productivity, safety, and precision. Common applications include:

Conveyor systems

Detect items moving on belts, helping control start/stop actions. This saves energy and prevents jams.

Robotics

Enable obstacle avoidance and navigation. Essential for autonomous robots in warehouses or assembly lines.

Assembly lines

Ensure correct placement of parts before welding, pressing, or fastening. Improve quality control.

Material handling

Used in sorting, packaging, and inventory management. Help ensure accurate product counts.

Safety systems

Act as protective barriers. If a person gets too close to dangerous equipment, sensors trigger emergency stops.

Process control

Monitor tank levels in food, chemical, and beverage industries. Maintain consistency and avoid spillage.

Benefits of Proximity Sensors

Using proximity sensors offers many benefits for industries:

Non-contact detection

No wear and tear on machines or the sensor itself. This extends life and reduces repair costs.

High reliability

Provide accurate and repeatable results even in demanding environments.

Durability

Built to handle dust, vibration, oil, and extreme temperatures.

Fast response

Can detect high-speed moving objects, critical in automotive and electronics manufacturing.

Versatility

Different types can detect metals, plastics, liquids, powders, and even transparent objects.

Challenges and Limitations

Despite their advantages, proximity sensors face some drawbacks:

Short range

Inductive and capacitive sensors have limited reach.

Environmental sensitivity

Dust, light, temperature, or humidity may cause errors in photoelectric or capacitive sensors.

Target restrictions

Some sensors work only with specific materials (e.g., inductive = metal only).

Interference

If multiple sensors are placed close together, signals can overlap, leading to false triggers. This requires careful design and spacing.

Future of Proximity Sensors

The future holds exciting developments:

IoT integration

Sensors will connect to IoT networks for real-time data sharing and remote monitoring.

Artificial Intelligence (AI)

Smart sensors will adapt to changes, predict failures, and improve efficiency.

Miniaturization

Smaller sensors will fit into compact devices, making them suitable for wearables and micro-machines.

Wireless sensors

These will reduce wiring costs and allow flexible installation.

Advanced sensing

Combining multiple sensor technologies (sensor fusion) will provide more accurate and intelligent decisions.

Expanding market

As industries move toward Industry 4.0 and smart factories, the demand for advanced sensors will grow rapidly.

Conclusion

Proximity sensors are fundamental to automation and smart industries. They detect objects without physical contact, which improves safety, reduces wear, and increases machine life.

With different types available, they can adapt to a wide variety of applications, from robotics and conveyors to safety and process control.

Although they face challenges such as limited range and environmental interference, ongoing innovation in AI, IoT, and wireless technologies will overcome these barriers.

In the future, proximity sensors will be even more central to smart factories and intelligent systems, enabling machines to interact seamlessly with their environment.

FAQ: What is a Proximity Sensor in Automation?

What is the difference between inductive and capacitive sensors?

Inductive sensors detect only metals, while capacitive sensors can detect both metallic and non-metallic objects such as liquids and plastics.

Which proximity sensor works best in dirty or oily environments?

Inductive sensors are the most reliable in harsh and contaminated conditions.

Can proximity sensors detect transparent objects?

Yes, photoelectric sensors are designed to detect transparent items like glass or thin plastics.

What industries rely most on proximity sensors?

Automotive, robotics, packaging, food and beverage, and warehouse logistics.

Are proximity sensors expensive?

Prices vary depending on type and range, but they are generally affordable considering the efficiency and reliability they bring to automation systems.