Programmable Logic Controllers (PLCs) sit at the heart of modern industry. They control machines, production lines, and entire plants.

A well-written PLC program can make a factory run smoothly while a poorly written one can cause downtime, safety issues, and costly repairs.

Programming a PLC is not just about making it “work.” It’s about making it reliable, safe, readable, and easy to maintain.

Many beginners, and even experienced programmers, fall into common traps. The good news? Most of these mistakes can be avoided with awareness and good habits.

This article explores the most common PLC programming mistakes. We’ll explain why they happen, what problems they cause, and how to avoid them.

Whether you’re a student, technician, or engineer, these lessons can save you time, stress, and money.

Mistake 1: Poor Documentation

One of the most overlooked parts of PLC programming is documentation. We usually rush to write code and forget to label inputs, outputs, or describe logic.

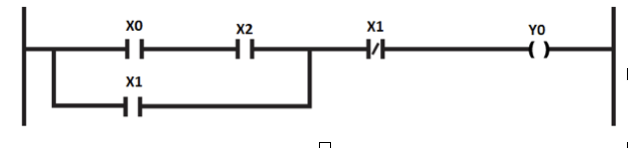

If you re-open the same program in the future, you will see hundreds of rungs, all with cryptic tags like the one shown in the figure below. You have no idea what they control. Troubleshooting becomes a difficult task.

Problem: ItMakes maintenance slow; Leads to confusion for others (or even yourself); Increases risk of errors when modifying code.

Avoidance: Use clear tag names. Instead of “X0, X1, Y0, Y1” use “ReadyToRun.”, add rung comments to explain what each section does and keep a separate document with I/O lists, wiring diagrams, and descriptions. See the figure below:

Takeaway: Good documentation is like leaving a roadmap for the next person and sometimes, that “next person” is you.

Mistake 2: Overcomplicating the Code

“The more complex the code, the smarter it looks”, this is a belief to some programmers. The truth is the opposite. Overcomplicated logic is harder to read, harder to debug, and more prone to failure.

Problem: Increases programming time, makes troubleshooting difficult and confuses technicians who may not be programmers.

Example:

Instead of using three rungs with simple logic, someone nests ten different conditions into one rung. The machine may still work, but no one else understands how.

Avoidance: Keep logic simple, one rung should handle one clear task, break large processes into smaller sections and use function blocks or subroutines for repeated logic.

Takeaway: Clarity beats cleverness in PLC programming.

Mistake 3: Ignoring Safety

PLCs often control equipment that can harm people. Any mistake here isn’t just expensive, it can be deadly.

Common safety mistakes include:

- Forgetting emergency stop circuits.

- Relying only on software for safety instead of hardware interlocks.

- Not handling fault conditions properly.

Problem: Risk of injury or death, legal and financial consequences and loss of trust in the system.

Avoidance: Always design safety circuits in hardware first (e.g., safety relays, contactors), use safety-rated PLCs when needed and program fault detection and safe shutdown sequences.

Takeaway: Safety should never be an afterthought.

Mistake 4: No Simulation or Testing

Many beginners write the code and immediately load it into the PLC. They skip simulation or offline testing. This is risky.

Problem: Errors appear only during machine operation, can cause equipment damage and/or wastes production time.

Avoidance: Use simulation tools built into programming software, test logic in small parts before full deployment and validate with the team before running on real hardware.

Takeaway: Testing saves time in the long run.

Mistake 5: Poor Handling of Inputs and Outputs

A common error is assuming that inputs and outputs always behave perfectly. But in the real world, sensors fail, signals bounce, and wiring gets loose.

Examples of mistakes:

- Ignoring sensor failure scenarios.

- Driving outputs directly without considering feedback

- Not debouncing mechanical switches.

Problem: Causes false triggers, leads to unexpected machine behavior and/or can create unsafe conditions.

Avoidance: Add timers or filters for noisy signals, always check for signal validity and add diagnostics for input and output status.

Takeaway: Think about the “real” environment, not just the code.

Mistake 6: Ignoring Standard Programming Practices

Standards for naming, structuring, and documenting PLC code, is essential to every company or industry. Ignoring them makes your program look like a mess.

Problem: Makes collaboration hard, slows down troubleshooting and/or creates inconsistency across machines.

Avoidance: Follow IEC-61131-3 programming standards, use consistent naming for tags and variables and stick to templates or guidelines provided by your company.

Takeaway: Standards exist to make everyone’s life easier.

Mistake 7: Not Planning Before Coding

Jumping straight into programming without planning is a classic mistake. A PLC program is like a building. Without a blueprint, it collapses.

Problem: Leads to messy logic, misses important steps in the process and/or wastes time rewriting code.

Avoidance: Write down the sequence of operations first, draw flowcharts or state diagrams and discuss the plan with colleagues before coding.

Results: Good planning reduces mistakes later.

Mistake 8: Forgetting About Maintenance

A PLC program is rarely “done.” Over time, technicians may need to adjust, expand, or troubleshoot it. If you don’t think about them, you make their job harder.

Problem: Increases downtime during repairs, creates frustration for maintenance staff and/or makes your system unpopular with the team.

Avoidance: Use clear labels and comments, group related logic together and provide clear diagnostic messages on HMIs.

Takeaway: A program that’s easy to maintain is a program that lasts.

Mistake 9: Overusing Timers

Timers are useful, but too many programmers use them as a crutch. For example, instead of checking when a motor is actually running, they just “wait 5 seconds” before moving on.

Problem: Makes the system slow, fails if equipment doesn’t behave as expected and/or creates hard-to-troubleshoot delays.

Avoidance: Use sensors and feedback whenever possible, apply timers only when necessary and document why each timer is used.

Takeaway: Timers should support logic, not replace it.

Mistake 10: Not Considering Power Loss or Restarts

What happens when the PLC loses power? What if the machine restarts after a fault? Many programmers don’t think about these cases.

Problem: Motors may start unexpectedly, equipment may reset to unsafe states and/or production data may be lost.

Avoidance: Define safe startup conditions, save critical data in retentive memory and add logic to handle controlled restarts.

Results: Always expect the unexpected.

Mistake 11: Lack of Version Control

In many plants, different people modify the same PLC program over time. Without version control, you lose track of changes.

Problem: Hard to know which version is correct, risk of reintroducing old bugs and/or wastes time comparing files manually.

Avoidance: Use version control software (Git, SVN, etc.), keep backup copies with clear version numbers and document changes in a log.

Takeaway: Version control prevents chaos.

Mistake 12: Ignoring Communication Issues

Modern PLCs often communicate with HMIs, SCADA systems, or other PLCs. Poorly handled communication causes big problems.

Common issues:

- No error handling when messages fail.

- Overloading the network with too many updates.

- Using unclear data mapping.

Problem: Causes slow or unreliable systems, leads to wrong data on screens and/or creates headaches for IT teams.

Avoidance: Test communication under real conditions, use retries and error handling and document data addresses clearly.

Takeaway: Communication is as important as logic.

Mistake 13: Forgetting Scalability

Many programmers only write code for today’s needs. But machines often evolve. If your code doesn’t scale, future upgrades become painful.

Problem: Hard to expand the program, leads to rewrites and/or costs more in the long term.

Avoidance: Use modular design, plan for extra I/O and functions and think about future needs, not just current ones.

Takeaway: Scalable code saves time later.

Mistake 14: Relying Too Much on Copy-Paste

Copying and pasting code may seem efficient. But without careful review, it spreads mistakes everywhere.

Problem: Duplicates errors, creates inconsistent logic and/or makes debugging harder.

Avoidance: Reuse logic with structured programming, not blind copy-paste; review every section after copying and use templates where possible.

Takeaway: Copy-paste is a tool, not a solution.

Mistake 15: Forgetting the Human Factor

At the end of the day, humans use and maintain PLC-controlled machines. Programs that ignore the human factor cause frustration.

Problem: Operators struggle with unclear HMIs; maintenance takes longer and/or training new staff becomes harder.

Avoidance: Design user-friendly HMI screens, show clear alarms and messages and Think from the operator’s perspective.

Takeaway: A program should serve people, not confuse them.

Conclusion: Common PLC Programming Mistakes to Avoid

This article discussed the most common PLC programming mistakes. It explained why they happen, what problems they cause, and how to avoid them.

After revised these details, we could dare to say that PLC programming is more than writing logic.

It’s about creating systems that are safe, reliable, and easy to maintain. The mistakes we’ve covered poor documentation, overcomplicated code, ignoring safety, skipping testing, and more, are common but avoidable.

Good programming comes from habits: plan first, keep things simple, document everything, and always think about safety.

Remember that your program will live on long after you write it. Someone else may maintain it, modify it, or rely on it to keep a machine running.

Avoiding these mistakes won’t just make you a better PLC programmer. It will make you a more valuable engineer, a trusted teammate, and someone who builds systems people can rely on.

FAQ: Common PLC Programming Mistakes to Avoid

What are the most frequent PLC programming mistakes?

Naming few: Neglecting documentation; Hard-coding values; Overcomplicating logic; Poor naming and lack of comments; Skipping requirement planning.

How can I improve naming and comments in PLC programs?

Use descriptive tags, Motor_Start; Write comments that explain “why”, not just “what.”; Adopt a standard naming convention use prefixes (like in_, out_, aux_) and stay consistent.

Why is planning before programming important?

Skipping system requirements invites hidden bugs and unpredictable behavior. Planning ensures you: Capture every operational requirement, including safety and timing; Break down functionality clearly using flow charts or P&IDs; Avoid scope drift and costly revisions.

How do I avoid overcomplicated logic?

Modularize: Break logic into small, reusable function blocks or routines; Eliminate redundancy: Avoid replicating logic across different sections; Follow structured design: Keep branching and nesting shallow for better readability

What are the downsides of hard-coding values?

Every change demands reprogramming, PLC download, and revalidation; Instead, use variables or HMI-alterable parameters so adjustments don’t require touching the core code

What is insufficient error-handling, and why does it matter?

Neglecting fault conditions (like sensor failures or network errors) can allow the PLC to behave unpredictably.

What errors happen due to poor testing?

Mistakes that slip into live systems often cause: unexpected stoppages or unsafe behavior; Missed edge-case bugs (like sensor delays or unusual system states).

What common mistakes do real-world programmers face?

From practitioner discussions: Dumb tag names and inconsistency in programming and naming conventions; “Designing for machinery but not HMI—like setting an indicator bit for a fraction of a second, which can cause freeze-ups if communication fails.