In modern industrial automation, systems have evolved to handle complex processes with high efficiency and reliability. Among the most advanced solutions is the Distributed Control System (DCS).

It enables operators to manage, monitor, and control processes that span large areas or involve many control loops.

By distributing intelligence across multiple controllers, a DCS ensures smoother operation, faster response, and better fault isolation compared to centralized systems.

This article studies what a DCS is, how it works, its main components, advantages, and how it differs from other automation systems.

It also explores its applications and the role of modern technologies in shaping its future.

What is a DCS?

A DCS is an industrial control system in which control elements are distributed throughout a plant rather than located in one central place.

Each process area has its own local controller connected to field devices such as sensors and actuators.

These controllers communicate with operator stations and a central supervisory computer through a communication network.

In simple terms, a DCS divides control tasks among multiple processors that share data and coordinate through a communication bus.

This allows the system to perform automatic control and continuous monitoring while keeping centralized supervision.

The Concept of Distribution

In a traditional control system, one central controller manages the entire process. This creates limitations in reliability and scalability.

A DCS solves these problems by distributing the control task among several smaller units placed near the process areas.

Each unit independently manages its section while communicating with the rest of the system.

This distributed structure reduces wiring costs, improves reliability, and provides faster responses to process changes.

The latter also simplifies maintenance, since failures can be isolated and corrected without shutting down the whole system. Finally, it allows easy expansion as new process units are added to the plant.

Architecture of a DCS

The DCS follows a hierarchical structure divided into four main levels: field, control, supervisory, and information.

At the field level, there are sensors, transmitters, actuators, and control valves.

These devices measure physical quantities such as temperature, flow, or pressure and send signals to the control level.

The control level includes distributed controllers or process stations. These controllers execute algorithms such as PID or sequence control.

They receive data from the field devices, process it, and send commands to actuators.

The supervisory level consists of operator stations and Human-Machine Interfaces (HMIs).

This level provides visualization, alarm handling, and data trending. Operators can monitor the entire process, modify setpoints, and take manual control when necessary.

Finally, the information level includes servers, engineering stations, and databases. This level handles configuration, data storage, system integration, and communication with business systems.

Components of a DCS

A complete DCS is built from both hardware and software elements. The hardware components include field devices, input/output modules, controllers, operator stations, engineering workstations, and communication networks.

Sensors and transmitters provide the raw data. Actuators and valves perform the physical control actions. Controllers are the brain of the system, running the control algorithms in real time.

Operator stations display process data and alarms. Engineering stations are used to configure and maintain the system, while communication networks ensure data flow among all these components.

On the software side, a DCS includes control programs, supervisory applications, and databases. Control software defines how the system reacts to process changes. Supervisory software handles alarm management, trending, and visualization.

Database software stores historical data for later analysis and reporting. Together, these software tools make configuration, monitoring, and diagnostics easier and faster.

Working Principle of a DCS

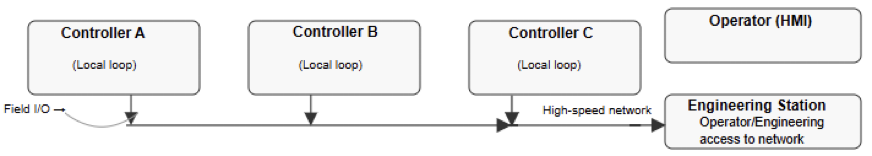

The operation of a DCS is based on the concept of distributed intelligence combined with centralized supervision. Each controller collects data from the sensors connected to it.

After that, the controller executes the programmed control algorithms, and sends commands to the actuators. These actions happen continuously and independently in each control area.

Meanwhile, all controllers exchange data with the operator station. The operator can see the status of the entire plant, acknowledge alarms, and modify process setpoints.

The engineering station allows maintenance engineers to modify logic or perform diagnostics without interrupting production. Communication between components occurs through a high-speed network, ensuring fast data transfer.

If one controller or network segment fails, other parts of the DCS continue to operate normally. This provides robustness and fault tolerance.

Communication in a DCS

Efficient communication is essential for the DCS to function properly. It connects field devices, controllers, and operator interfaces, enabling real-time data sharing.

Most DCS networks use industrial communication protocols such as Foundation Fieldbus, Profibus-DP, Modbus TCP/IP, Ethernet/IP, or HART. These protocols ensure reliable data transfer even in harsh industrial environments.

To increase reliability, modern DCS systems include redundant communication paths. If one network link fails, data automatically re-routes through a backup channel.

Data flow occurs in both directions: from the field to the control room for monitoring and from the control room back to the field for command execution. See figure below.

Control Strategies Used in DCS

A DCS supports many control strategies to suit different industrial needs. The most basic is regulatory control, usually implemented through PID algorithms that maintain process variables at desired setpoints.

In more complex processes, sequence control is used to perform operations step by step, such as startup and shutdown.

Batch control manages processes that run in cycles, like in the food or pharmaceutical industries.

For higher efficiency, advanced process control uses predictive models to optimize performance.

Safety-related controls such as interlocks are also included to prevent unsafe operations.

These strategies can be combined and distributed across several controllers for coordinated control of the entire plant.

Advantages of a DCS

A DCS provides many advantages that make it ideal for large industrial plants. It improves system reliability by spreading control across multiple nodes, so a single failure does not cause total shutdown.

It also simplifies wiring because local controllers are placed near the process area, reducing the length of signal cables.

Response time is faster since control actions happen locally rather than traveling to a central computer.

The system is highly scalable, allowing new controllers or process units to be added without major redesign.

Operators benefit from centralized monitoring, where the entire plant can be viewed and controlled from one interface.

Maintenance is easier because faults can be identified quickly, and redundancy ensures continued operation during repairs.

Finally, DCS integrates smoothly with higher-level systems, helping management make better decisions based on process data.

DCS vs. Other Industrial Control Systems

This section indicates an overview and comparison of DCS with other existing industrial control systems.

Comparison of Distributed and Centralized

In a traditional centralized system, one main computer or controller handles all control tasks.

A DCS decentralizes this by breaking the control process into smaller, manageable tasks assigned to individual controllers.

Comparison of DCS and PLC

Although DCS and PLC systems share some features, they are designed for different purposes.

A DCS is mainly used for continuous process control in industries such as power, oil, gas, and chemicals.

It handles large numbers of analog loops and provides smooth control over long durations.

On the contrary, a PLC is more common in discrete or machine automation such as packaging, assembly, or robotics.

It executes logic faster and suits operations requiring quick, on-off actions. In short, a DCS focuses on process stability and coordination, while a PLC focuses on speed and event driven tasks.

Modern systems often integrate both, using PLCs for specific machines and a DCS for overall plant control.

Comparison of DCS and SCADA

DCS and SCADA systems may appear similar because both involve monitoring and control, but their purposes differ.

A DCS is mainly used within one industrial plant for local control of continuous processes. It provides real-time feedback and closed-loop control.

SCADA systems, on the other hand, are used over large geographical areas, such as pipelines, water distribution networks, or power grids.

They focus on data collection, remote monitoring, and supervisory control rather than direct regulation of process variables.

In essence, DCS is for localized, process intensive industries, while SCADA is for wide area data supervision.

Applications of DCS

The DCS is used wherever continuous and reliable control is required. In the oil and gas industry, it controls refinery units, drilling operations, and pipeline systems.

In chemical and petrochemical plants, it maintains temperature, pressure, and flow to ensure product consistency.

In power generation, DCS manages boiler, turbine, and generator systems, ensuring stable energy production.

Water and wastewater treatment plants rely on DCS to maintain water quality and flow balance.

The pharmaceutical and food industries use it to control batch processes, ensuring precise recipe management and temperature control.

Other sectors like pulp and paper, cement, and steel manufacturing also depend on DCS to automate complex, interconnected operations.

Redundancy and Reliability

Reliability is one of the strongest features of a DCS. To achieve this, redundancy is built into key parts of the system.

Redundant controllers, power supplies, networks, and operator stations ensure continuous operation even if one element fails.

For example, in a hot standby configuration, the backup controller runs simultaneously with the main one.

If the main controller stops responding, the backup immediately takes over without interrupting the process.

This design prevents production losses and enhances plant safety.

Integration with Modern Technologies

Modern DCS systems are evolving rapidly with new technologies. The Industrial Internet of Things (IIoT) allows smart sensors to communicate data in real time, giving better visibility into equipment performance.

Cloud integration enables remote monitoring and analytics, allowing engineers to access process data from anywhere.

Cybersecurity features such as encryption, user authentication, and firewalls protect the control network from external attacks.

Artificial Intelligence and Machine Learning are being integrated to predict failures, adjust control parameters, and optimize performance.

The modern DCS is no longer limited to control, it is becoming an intelligent network for decision support.

Maintenance and Troubleshooting

Proper maintenance keeps a DCS operating efficiently. Regular checks include verifying communication links, updating firmware, and calibrating sensors.

The engineering workstation provides diagnostic tools that help detect faults early.

Operators and maintenance teams can use historical data and alarm logs to locate issues quickly. Predictive maintenance, powered by data analytics, is now common.

It identifies signs of equipment wear or network problems before they cause system failure. This proactive approach saves time and reduces unplanned downtime.

DCS Lifecycle and Upgrades

A DCS typically has a lifespan of 10 to 15 years. Over time, hardware becomes outdated and software may no longer support new communication standards.

Upgrading involves migrating to newer platforms while preserving existing configurations.

Manufacturers offer migration tools to help transition smoothly. Upgrades bring faster processors, modern HMIs, improved cybersecurity, and easier integration with enterprise systems.

Keeping the DCS up to date ensures reliability and maintains compatibility with the latest industrial technologies.

Leading DCS Manufacturers and The Future

Several major companies design and supply DCS solutions worldwide. Siemens offers the SIMATIC PCS 7 system.

Honeywell provides Experion PKS, Emerson delivers DeltaV, and ABB supplies System 800xA.

In addition, Yokogawa offers CENTUM VP, and Schneider Electric provides the EcoStruxure Foxboro DCS.

Although each system has unique features and architecture, all share the same core principles of distributed control, real-time monitoring, and system redundancy.

The future of DCS is closely linked with digital transformation. The trend is moving toward modular DCS designs, which make it easier to expand or modify process areas.

Edge computing will process data closer to the source, reducing latency and network load.

Wireless communication and mobile devices will allow operators to monitor systems on the move.

Virtualization will simplify system backups and maintenance. Artificial Intelligence will enhance process optimization and fault prediction.

Together, these technologies will create a smarter, more flexible DCS ready for the industry 4.0.

Conclusion

This article studied the Distributed Control System (DCS), explaining its structure, operation, and significance in process automation.

A DCS distributes control across multiple nodes while maintaining centralized supervision, ensuring high reliability and efficiency.

It improves safety, reduces wiring complexity, and allows for scalable and continuous process control.

With advancements in digital communication, IIoT, and AI, modern DCS systems are becoming more intelligent and connected than ever before.

As industries evolve, DCS will remain the core technology that keeps complex processes stable, optimized, and productive.

FAQ: What is a DCS?

What is a DCS?

A DCS is a computerized system that automates industrial equipment used in continuous and batch processes, enhancing safety and efficiency.

How does a DCS work?

It distributes control functions across various subsystems, allowing for decentralized control and real-time process management.

What are the key components of a DCS?

Key components include field devices, controllers, human-machine interfaces (HMIs), and communication networks.

What industries use DCS?

Industries such as oil and gas, power generation, water treatment, and chemical manufacturing utilize DCS for process automation.

What are the benefits of a DCS?

Benefits include improved process control, enhanced safety, reduced operational costs, and increased system reliability.

How does a DCS differ from a PLC?

A DCS is designed for large-scale, continuous processes, offering centralized supervision and decentralized control, whereas a PLC is typically used for discrete, sequential control tasks.

Can a DCS connect to the cloud?

Yes, modern DCS architectures often include cloud connectivity for remote monitoring and data analytics.

Is a DCS scalable?

Yes, DCS can be scaled to accommodate the needs of small to large industrial operations.

What is the role of HMIs in a DCS?

HMIs provide operators with graphical interfaces to monitor and control processes in real-time.

How does a DCS enhance safety?

By enabling real-time monitoring, automatic fault detection, and alarm management, a DCS helps prevent accidents and ensures safe operation.