In the sphere of modern manufacturing, Programmable Logic Controllers (PLCs) and robotics are fundamental to automation. PLCs coordinate the actions of robots and machines.

They ensure tasks happen in the right order, at the right time. The result: safer, faster, more reliable production.

As we enter the era of Industry 4.0, the link between PLCs and robots grows deeper.

Together they bring intelligence, flexibility, and adaptability to manufacturing systems.

In this article, we explore PLCs in robotics. We cover how PLCs work, how they integrate with robots, and where this union is heading.

What Is a PLC?

A Programmable Logic Controller is an industrial computer built rugged to endure harsh conditions.

Dust, vibration, temperature swings, PLCs survive them all. PLCs monitor signals from sensors.

They run a control program. Based on the logic, they send commands to actuators. Actuators include motors, solenoids, valves, and more.

You may think of the PLC as the brain of a cell. It reads the world. It makes decisions. Then it acts on them.

Key Components of a PLC

A typical PLC setup includes:

- CPU (Central Processing Unit): Executes the control logic.

- I/O Modules (Input/Output): Interface to sensors and actuators. Inputs are signals from switches, encoders, sensors. Outputs drive motors, lights, pistons.

- Power Supply: Provides stable voltage to the PLC and modules.

- Programming Device / Software: A PC or handheld unit used to write and download code.

- Memory / Storage: Stores the program, data, variable tables.

Some systems include redundancy modules or backup power. They add reliability in critical installations.

The PLC Scan Cycle

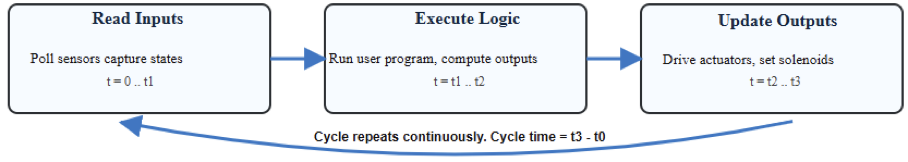

PLCs run on a continuous loop, called the scan cycle. It has three main phases:

- Read inputs: The PLC polls all input modules. It captures sensor states.

- Execute logic: It processes the user’s program. It updates internal memory and decides what outputs should change.

- Update outputs: It writes new values to output modules, driving actuators.

Then it repeats. This cycle happens many times per second. The speed depends on CPU power and program size.

Because of this cycle, PLCs behave deterministically. They guarantee timely responses. That quality is essential in robotics.

The Role of PLCs in Robotics

PLCs play many roles within robotic automation. Their basic job is coordination. They bring together robots, conveyors, sensors, and other devices. Here next are key functions.

Orchestration and Synchronization

In complex lines, many robots operate in tandem. Each must act in sync. The PLC coordinates timing.

For example, in automotive welding, one robot must wait until another finishes a seam before moving. The PLC ensures smooth transitions.

Communication Hub

PLCs link robotic controllers with factory systems. They connect to HMIs (Human-Machine Interfaces), SCADA systems, databases, and MES (Manufacturing Execution Systems). They serve as communication bridges between devices.

Safety and Control

Safety is nonnegotiable. PLCs monitor emergency stops, door switches, light curtains, and more.

When unsafe conditions arise, a PLC can shut down motion. It can halt robots mid-task if needed.

Flexibility and Adaptability

Production needs change. New part variants appear. The layout evolves. PLCs allow logic to be modified.

Engineers can reprogram sequences or add new branches without hardware changes.

Integrating PLCs with Robot Systems

There are multiple ways to connect a PLC to a robot or a set of robots. The choice depends on complexity, speed, and application size.

I/O-Based Communication (Handshaking): This is the simplest method. Digital signals are exchanged. For instance:

- The PLC sets an output bit “Robot_Start” to ON.

- The robot sees that bit on its input side and begins operation.

- When done, the robot turns ON a “Robot_Done” signal as an output.

- The PLC sees “Robot_Done” and moves the next step.

This is often called handshaking (see figure below). It is suitable for basic tasks with limited data exchange.

Network-Based Communication: For more advanced tasks, you need richer interaction. Robots and PLCs communicate over networks (see figure below). They share data, diagnostics, and commands.

Common industrial protocols include EtherNet/IP, PROFINET, Modbus TCP, EtherCAT and DeviceNet. These protocols are designed to enable fast cyclic data exchange, configuration and diagnostics, plus integration with higher level systems.

Hybrid Approaches: Often, systems use a mix. Critical, fast signals may be handled via hard I/O. Less time sensitive data is sent over networks. This hybrid method balances reliability and flexibility.

Programming PLCs for Robotics

Writing PLC code for robotic systems adds complexity. The software must handle timing, errors, and synchronization.

IEC 61131-3 Languages

PLC programming uses standard languages. The main ones are:

- Ladder Logic (LD): Visual, uses contacts and coils.

- Structured Text (ST): Textual, similar to high-level languages.

- Function Block Diagram (FBD): Blocks that process inputs to outputs.

- Sequential Function Chart (SFC): Defines steps and transitions for sequences.

Engineers often combine these to capture different kinds of logic.

Real-Time Response

In robotics, delays are critical. The PLC must react quickly when sensors change. So, timing constraints must be respected. Loops must avoid blocking. Tasks must be prioritized.

Safety Interlocks

Safety logic must be integrated. You will include:

- Conditions gating motion

- Emergency stop logic

- Redundant checks

- Mode switches (e.g., auto, manual, maintenance)

Synchronization

Robots must act together or in sequence. You must coordinate start, stop, and wait states. Timing must align exactly.

Error Handling

Robots can fail. Sensors might misread. The PLC logic must detect and handle errors. This includes retries, alarms, rollbacks, safe shutdowns.

Diagnostic and Maintenance Support

PLC programs often include diagnostic flags, status bits, and logging. These help maintenance staff see what went wrong, and where, when.

Real-Life Example: Automotive Welding Cell

Welding cell in a car factory is a typical use of joint PLC-Robots, so let us study it:

System Overview

- A car body arrives on a conveyor.

- Robots perform welding on joints.

- Sensors verify alignment.

- Fixtures lock the body.

- Once welding is done, the body moves out.

Role of the PLC

The PLC controls conveyors, clamps, gates, and robots. It ensures sequence:

- Conveyor brings the body.

- Sensors detect body in position.

- Fixtures close and lock.

- PLC signals robot to start welding.

- Robot sends “done” when finished.

- PLC triggers unlocking and conveyor advance.

- Repeat.

The PLC also monitors safety sensors around the cell. If a door opens, it halts welding and motion instantly.

Advantages Achieved

- Cycle times shrink.

- Defects drop.

- Coordination is precise.

- Downtime is manageable via diagnostics.

Benefits of PLCs in Robotics

Using PLCs in robotic automation brings numerous advantages. Let’s list them:

Robustness & Reliability

PLCs are built for industrial conditions. They run for years with minimal failure.

Deterministic Control

The scan cycle gives predictable timing. Robots act on schedule.

Scalability

You can expand I/O or add modules as the system grows.

Interoperability

PLCs support many protocols. They integrate with many devices.

Ease of Troubleshooting

Engineers can debug ladder logic. I/O modules often have status LEDs.

Safety Support

Many PLCs include safety modules or safety logic features.

Flexibility

Change logic rather than rewiring hardware. Support variant production.

Downsides of PLCs in Robotics

On the other hand, they have downsides too. These include:

Complex integration

High-level integration with robots might be challenging. Careful design is required.

Skill requirement

Engineers must know PLC programming and robotic systems.

Limited computation

PLCs may lag behind industrial PCs in raw data handling or vision processing.

Cybersecurity risks

Networked PLCs can be targets. Security must be managed.

Challenges and Considerations

When implementing PLC-robot systems, many challenges arise. Below are some of them:

Timing and Synchronization

Some robots demand microsecond timing. PLCs must be fast enough. You must ensure the scan time is short.

Signal Latency

Networks introduce delays. Use deterministic protocols. Keep critical signals via I/O if latency is too high.

Safety Certification

For robotic systems, safety standards matter. ISO 13849, IEC 61508, etc. The PLC logic must meet those standards.

Diagnostic Gap

Robots have their own controller. Some errors may be hidden inside the robot. A coordinated diagnostic approach helps.

Commissioning & Virtual Testing

Testing logic before hardware arrives is important. Virtual commissioning (simulation) helps reduce on-site surprises.

Compatibility

Robots and PLCs from different vendors may speak different protocols. Ensuring compatibility is vital.

Maintenance over Lifecycle

Systems last many years. Technology evolves. The control architecture must allow upgrades and maintenance.

Future of PLC-Robotics Systems

In this section, let us briefly dive into more advanced themes in PLC-robot integration.

IoT and Edge Computing

PLCs now often act as edge devices. They collect data. They analyze trends. They send insights to the cloud.

Robots share data on cycles, faults, utilization. Predictive maintenance becomes possible.

Artificial Intelligence and Adaptive Control

Some systems include AI modules. The PLC may feed data to a learning system. That system may advise changes like speed, path, or sequence.

Virtual Commissioning & Digital Twins

Engineers build digital replicas of the line. They run PLC code and robot code together in simulation. Problems are ironed out before real deployment.

Wireless and Fieldbus Technologies

Wireless such as WiFi, 5G are growing. Some noncritical signals may move over wireless links. Fieldbus continues for hard real-time signals.

Enhanced Security

As systems get networked, cybersecurity grows in importance. Techniques include firewalls, network segmentation, encryption, intrusion detection, and secure boot.

Cloud Integration & Analytics

Data from PLCs and robots get aggregated in the cloud. Big data analytics optimize throughput, quality, energy usage.

Key Takeaways: PLC in Robotics

This article introduced PLCs in robotics, explained how PLCs work, how they can be integrated with robots, and where this union is heading.

This helped to discover that PLCs and robotics form a powerful duo in modern automation.

PLCs act as the orchestrator by monitoring sensors, run logic, and command devices.

Robots bring precision motion and task execution. Together, they make manufacturing systems robust, flexible, and efficient.

Integration can be simple via digital I/O or sophisticated via industrial networks.

Programming demands careful attention to timing, safety, and error handling. Real examples, like welding cells, illustrate how PLCs elevate performance and reliability.

Challenges remain and this is why engineers must bridge hardware, software, and communication domains. Cybersecurity, longevity, and compatibility are ongoing concerns.

PLCs evolving with AI, IoT, edge computing, and simulation open new horizons. Finally, we can windup that PLCs are indispensable in robotic systems.

They will remain central as automation advances, as their role will only grow in smarter, more connected factories.

FAQ: PLC in Robotics

What is a PLC in robotics?

A PLC (Programmable Logic Controller) is an industrial controller that monitors sensors, runs logic, and drives actuators—coordinating robots and other equipment.

Why use a PLC instead of just a robot controller?

PLCs handle system-level tasks (conveyors, interlocks, safety, coordination). They let robot programs focus on motion.

What types of communication do PLCs use with robots?

They use simple I/O “handshaking” or network protocols like Ethernet/IP, PROFINET, Modbus, EtherCAT.

Can a robot controller alone replace a PLC in small systems?

Yes, in simple, single-robot setups some modern robot controllers include PLC-like capabilities.

What programming languages are used for PLCs in robotics?

Common ones are Ladder Logic, Structured Text, Function Block Diagram, and Sequential Function Charts (IEC 61131-3).

What is the PLC scan cycle?

The PLC continuously executes a loop: read inputs – run logic – update outputs, then repeats at high speed.

How does a PLC contribute to safety in robotic cells?

PLCs monitor safety inputs (emergency stop, door interlocks, light curtains). They can shut down motion or disable outputs when hazards occur.

Can PLCs handle vision and AI tasks in robotics?

Generally, heavy vision or AI processing is offloaded to specialized hardware. PLCs may integrate the results or trigger actions.

What are the limitations of using PLCs in robotics?

Limitations include less raw computing power compared to PCs, protocol compatibility issues, and need for expert integration.

Are PLCs suitable for harsh industrial environments?

Yes, PLCs are ruggedized for extremes of temperature, vibration, electrical noise, and dust.

How do you choose the right PLC for a robotic system?

Consider number of I/O, required network protocols, processing speed, safety features, expansion capability, and environment.

What is “hybrid” integration of PLC and robot?

Hybrid integration mixes hardwired I/O for critical signals and network communication for high-bandwidth or diagnostic data.

How do PLCs scale in multi-robot systems?

In complex systems, one PLC can orchestrate many robots, conveyors, sensors, and HMIs over industrial networks.

Does using a PLC introduce cybersecurity risks?

Yes. Networked PLCs need security measures (segmentation, firewalls, encryption) to reduce vulnerability.

How is diagnostics and maintenance handled in PLC‐robot systems?

PLCs expose status bits, error codes, logs, and diagnostics interfaces to simplify troubleshooting.