When starting an automation project, whether for a small home system or a large industrial process, choosing the right controller is the first key step.

Two popular options are the Programmable Logic Controller (PLC) and the Arduino microcontroller board.

Both can automate processes, but they differ in design, function, and purpose. A PLC is an industrial grade, durable computer built for demanding environments.

Arduino, on the other hand, is an open source, low cost, and flexible tool ideal for learning, testing, and small projects.

This article studies how PLC and Arduino differ in purpose, structure, and use in automation systems. Understanding these differences helps ensure success in any automation project.

What is a PLC?

A Programmable Logic Controller (PLC) is a tough digital industrial computer used to automate manufacturing and process control. It was created to replace hardwired relays with software based logic.

PLCs can withstand heat, dust, vibration, and electrical noise, making them ideal for industrial use.

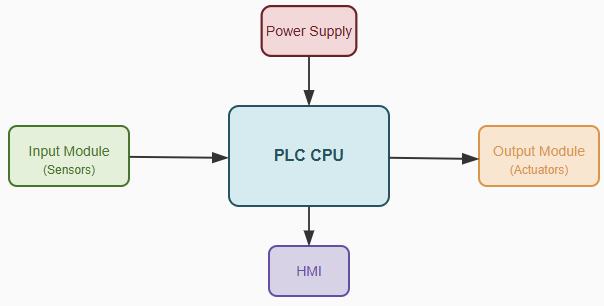

They are the backbone of modern automation systems. A typical PLC has five key parts. The Central Processing Unit (CPU) is its brain. It executes the control program.

In addition, the input modules receive data from sensors and field devices. Output modules send signals to actuators such as motors, solenoids, and valves. The power supply provides stable voltage to all components.

Finally, communication ports allow data exchange between the PLC, other controllers, HMIs (Human-Machine Interfaces), and supervisory systems.

Figure below illustrates a simple block diagram showing sensors connected to input modules, the CPU at the center, output modules linked to actuators, and an HMI connected through communication ports.

What is an Arduino?

An Arduino is an open source electronics platform built for easy hardware and software use.

It is a microcontroller board, a small computer on a single chip mainly used for educational and experimental purposes.

Since arduino is affordable and simple, it’s excellent for beginners, students, and hobbyists.

An Arduino board contains a few essential parts. The microcontroller serves as the processor that runs uploaded programs.

Furthermore, it has digital and analog pins to connect sensors and actuators. A USB port is used for programming and data transfer. Finally, a power jack allows external power input for standalone operation. See the next figure.

Key Differences Between PLC and Arduino

The choice between PLC and Arduino depends on the environment, reliability needs, and project complexity.

PLCs are made for harsh industrial environments. They resist electrical noise, vibration, and extreme temperatures. Arduinos are best for clean, non-industrial settings unless modified.

In reliability, PLCs are superior because they include diagnostics, safety checks, and are built for continuous operation. Arduinos, while reliable for short term or light tasks, can fail under harsh or continuous conditions.

Programming also differs. PLCs use industrial languages like Ladder Logic, Function Block Diagram (FBD), and Structured Text. These languages are standardized under IEC 61131-3 and often require vendor specific software that can be expensive.

Arduino, in contrast, uses a simplified C++ based language through the open-source Arduino IDE. It’s beginner friendly but can be more challenging for complex logic.

In terms of I/O (Input/Output) capacity, PLCs are highly scalable. You can add extra modules for more signals and support a wide voltage range (24VDC, 120VAC, etc.). Arduino boards have a fixed number of I/O pins and handle low voltages (5V or 3.3V). To connect industrial sensors or actuators, external circuits or converters are required.

The cost difference is significant. PLCs have a high upfront cost due to their industrial grade hardware and licensed software. However, they are cost effective for large, complex systems that run for years.

Arduinos are very inexpensive, making them great for small projects, education, or prototyping.

When it comes to safety, PLCs include built in safety protocols, redundancy, and certifications such as SIL or PL. Arduinos have no such features and are not certified for industrial safety standards.

Troubleshooting is another key point. PLCs offer centralized diagnostic tools that make fault detection and correction easier. Arduino debugging is mostly manual, requiring deeper technical skills and patience.

In short, PLCs offer industrial robustness and reliability, while Arduinos provide flexibility and affordability for learning and experimentation.

When to Choose Each Platform

The correct choice depends entirely on what the automation project demands.

Choose a PLC when:

You are automating industrial manufacturing systems, such as assembly lines, conveyor systems, or robotic arms.

PLCs are also essential in critical systems like power plants or water treatment facilities where reliability and safety cannot be compromised.

They are ideal for large scale automation with many I/O points and complex control loops.

When a system must operate continuously for years without failure or requires precise, real-time control, a PLC is the correct choice.

Choose an Arduino when:

You are learning electronics or programming. Arduino is perfect for educational environments due to its simplicity and low cost.

It is also ideal for prototyping, allowing you to create proof of concept designs quickly before developing an industrial solution. Hobbyists use it for custom gadgets, home automation, and creative DIY projects.

Arduino is also suitable for simple automation, such as controlling lights, fans, or small motors.

It can serve as an embedded controller for devices where cost is more important than industrial reliability.

Hybrid Arduino Solutions

Recently, the boundary between PLCs and Arduinos is fading. New hardware combines open source flexibility with industrial strength.

These include Industrial Arduino boards like the Arduino Opta and advanced microcontrollers such as the ESP32.

They come with stronger protection, faster processors, and better connectivity, making them usable even in semi industrial environments.

Modern Arduino based platforms now offer:

- Higher processing power: Allow faster data handling and real-time operations.

- Enhanced connectivity: with builtin WiFi, Bluetooth, and Ethernet.

- Improved electrical protection: giving greater reliability for industrial like applications.

Such systems can perform many tasks once reserved for PLCs, especially in small scale or low risk industrial settings.

For example, a protected Arduino Opta can monitor sensors, control relays, and send data to the cloud via MQTT or Modbus TCP.

This hybrid evolution means engineers can now prototype with Arduino and later deploy upgraded, industrial ready versions without completely changing their software logic. See the following figure.

Take Aways: PLC vs. Arduino for Automation

This article detailed the main differences between PLCs and Arduino boards in the field of automation.

It explained how each platform is designed for specific environments and project needs.

This helped us to see that PLCs and Arduino boards are not rivals, they serve different purposes. The choice depends on project size, reliability needs, and budget.

For industrial, safetycritical, and long term operations, a PLC is indispensable. This is possible due to its durability, diagnostic tools, and compliance with industrial standards.

For learning, prototyping, and small-scale applications, Arduino provides unmatched affordability and flexibility.

As automation continues to evolve, hybrid controllers that merge open source design with industrial features are creating new opportunities.

They allow users to combine the best of both worlds: the accessibility of Arduino with the reliability of PLC systems.

Yet, professionals must still understand the strengths and limits of each platform. A PLC ensures industrial grade stability, while an Arduino empowers innovation and rapid experimentation.

Choosing wisely between them leads to efficient, safe, and cost-effective automation solutions.

Want to know more about similar topics? Please don’t forget to subscribe…!!!

FAQ: PLC vs. Arduino for Automation

Can an Arduino replace a PLC in industrial automation?

Not reliably because Arduino lacks the ruggedness, certifications, noise immunity, and built in safety features of PLCs.

Why use a PLC instead of Arduino for automation?

PLCs are built for harsh environments, offer diagnostics, modular I/O, and long-term stability.

What are the cost advantages of Arduino?

Arduino systems are much cheaper in hardware and software. Good for prototypes, learning, or small-scale applications.

What programming languages are used by PLCs vs Arduino?

PLCs support industrial languages like Ladder Logic, Structured Text, Function Block Diagrams. Arduino uses a C/C++ based environment.

Is Arduino safe for use in industrial control?

Generally no, it lacks certifications (e.g., SIL, PL), and needs extra protection for industrial usage.

Can an Arduino-based system run continuously for years?

It’s risky. Arduinos are less reliable long term in demanding environments unless heavily reinforced.

Is it good to use an Arduino or Arduino-based PLC for learning PLC programming?

Yes, Arduino PLC platforms support IEC languages and are a cost-effective starting point for learning.