An interlock is a safety method used to prevent dangerous electrical or mechanical conditions. It works by allowing one action only when another condition is met. This creates a controlled sequence.

The purpose is to avoid accidents. It reduces equipment damage. It ensures safe operation for people and machines. Interlocks appear in many systems. You can see them in motor control circuits, industrial machines, electrical panels, and household appliances.

The idea is always the same. It blocks unsafe actions. It also enables safe actions. Because of this, interlocks are key elements in modern safety designs. This article studies these interlocks, their types, applications, and design considerations.

What Is an Interlock?

An interlock is a control feature that forces equipment to operate in a safe and defined order. Its purpose is to prevent unsafe states by ensuring that one step can occur only when another step or condition has already been satisfied.

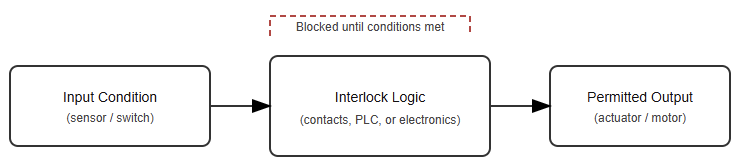

By doing so, an interlock protects both people and machines, reduces unexpected behavior, and improves reliability within the system. The following figure shows a block diagram that indicates input condition, interlock logic and permitted output.

How Do Interlocks Work?

An interlock works by checking a condition before allowing the next action to occur. It might read a switch, a status signal or a sensor Interlocks permit the operation only if the system is in a safe state. Otherwise, it blocks everything.

This creates a structured and predictable sequence and prevents equipment from performing unexpected actions.

Why Are Interlocks Important?

Interlocks are important because they reduce risks across electrical and mechanical processes. They stop unsafe operations before they occur. In addition, they prevent equipment from being damaged by incorrect sequences.

Through enforcing a structured and predictable order of actions, interlocks create a safer working environment. As a result, they reduce the chance of operator error. Without them, machines can enter hazardous modes that may lead to equipment failure or personal injury.

The next figure illustrates a flowchart of typical allowed against blocked conditions.

Types of Interlocks

Mechanical Interlocks

A mechanical interlock uses physical components such as pins or plates to enforce safe operation. It also employs sliding mechanisms.

These parts move only when the system reaches a safe condition, preventing two mechanical actions from taking place at the same time.

This reduces equipment conflict and avoids physical damage. Mechanical interlocks are often seen in switchgear. In this task, they prevent two breakers from being closed simultaneously.

Electrical Interlocks

Electrical interlocks rely on auxiliary contacts that change state when the main device is energized.

These contacts signal whether another device can or cannot operate, creating safe sequences within control circuits.

Electrical interlocks are widely used in motor starters, especially in forward-reverse and star-delta configurations.

In this case, they used to prevent contactors from energizing at the same time. This protects motors and prevents short circuits while still allowing simple and reliable operation.

Electronic Interlocks

Electronic interlocks use sensors and detection devices to evaluate conditions before allowing an output to activate.

It also applies digital logic circuits. Mechanical and electrical interlocks offer less flexibility than electronic interlocks.

The capability of checking multiple variables at once and handling advanced rules is the reason behind this.

These interlocks are common in modern automated machinery and integrate easily with PLC systems, making them suitable for applications that require complex safety logic.

Process Interlocks

A process interlock uses real process variables, such as level, flow, temperature, or pressure to determine whether the system can proceed. These interlocks ensure that each step occurs only when the process is stable and safe.

They are essential in power stations, fluid systems, refineries and chemical plants. A process interlock may stop a pump, close a valve, or disable a heater until measured conditions reach the required range.

The use of Interlocks

Motor Control Panels

Motor control panels use interlocks extensively to protect motors and operators. In forward-reverse systems, only one direction can be enabled at a time. Interlocks make sure the opposite contactor cannot energize.

Star-delta starters also depend on interlocks to prevent both contactors from closing together. If this happened, it would cause a direct short across the motor windings.

Electrical Breakers

To prevent two breakers from closing at the same time, most of the electrical breakers include mechanical interlocks.

This prevents back-feeding and protects personnel who may be performing maintenance. Interlocks also ensure that switching between utility and generator sources follows a safe and defined sequence.

Machine Safety Doors

As usually, most of the industrial machines contain moving part. So here the door interlocks are used to protect operators.

The machine stops immediately once the door opens and cannot restart until the door closes again. This prevents serious accidents during cleaning, setup, or maintenance.

Industrial Processes

Interlocks are found throughout industrial processes. A pump may operate only when a tank level is sufficient.

A valve may open only if the pressure is within limits. In addition, a heater may energize only when flow is detected.

These rules reduce hazards and prevent dangerous conditions from developing in continuous operations.

Elevators and Lifts

Door interlocks are essential to ensuring safety operation in elevator systems. If the doors are not fully closed and locked, the elevator must not make any movement.

This prevents passengers from being exposed to open shafts. Also, it protects the equipment from operating under unsafe conditions.

Home Appliances

Most of the household appliances use simple interlocks to improve safety. For instance, if door open a microwave oven must not run.

Also washing machine stops spinning when the lid is lifted. These interlocks prevent unnecessary wear on mechanical components and most importantly protect users.

Interlocks in PLC Systems

PLC-based interlocks offer advanced control. This is because the PLC can process many signals at once and apply detailed rules.

Shortly, the PLC evaluates inputs, compares them with programmed logic. Then it decides whether to energize or disable an output (actuator).

Timers, counters, and multiple condition checks can be part of the logic. Modern PLCs can also display specific interlock causes, which helps technicians diagnose issues more quickly.

Safety PLCs extend this concept by providing certified safety functions for high-risk environments.

Designing Good Interlocks

A good interlock design should remain simple and clear. This helps operators to understand it without difficulty.

Too many conditions or overly complex logic chains often lead to confusion. They are also a major source of and errors.

The system defaults to a safe state if power is lost or a component fails. Technically, this means interlocks should always be fail-safe. Reliable sensors and, when necessary, redundant signals help strengthen the design.

Clear indicators and alarms should be included so operators can easily see the interlock status. Proper documentation is essential and should explain each step of the sequence.

Common Mistakes in Interlock Design

A common error is depending only on software, since it can malfunction or be overridden.

For critical functions hardware-backup is often necessary. Another mistake is complicated logic sequences or creating overly long that make troubleshooting difficult.

Inadequate documentation often causes technicians to override interlocks, as the reason for their activation is not obvious.

It is equally important for designers to evaluate failure scenarios so that a sensor malfunction shifts the system toward safety rather than risk. Maintenance of Interlocks

Interlocks require regular inspection to remain effective. Mechanical parts can become misaligned, loosen or wear out. Electrical contacts must be tested periodically because may degrade or fail over time.

Sensors require calibration because pressure switches, limit switches, and temperature sensors can drift.

PLC logic must also be reviewed, especially after changes to wiring or programming. Indicators and alarm systems need to be verified because operators depend on them to make safe decisions.

Conclusion

This article reviewed the purpose, operation, and importance of interlocks in electrical and mechanical systems.

It showed that in many mechanical and electrical systems interlocks are essential safety features.

They ensure safe operation by enforcing specific conditions before a device or process can continue. They prevent accidents.

They also reduce equipment damage. Interlocks provide structure and order to procedures.

This makes systems predictable. It also gives operators confidence. Interlocks appear everywhere, from simple home appliances to large industrial plants. They may be mechanical, electrical, electronic, or software-based.

Each type serves the same goal. They block unsafe actions. They allow safe ones. With proper design and maintenance, interlocks become a powerful layer of protection and reliability in modern engineering systems.

FAQ: What is an Interlock?

What is an interlock?

A safety feature that prevents a machine or process from operating unless specific conditions are met.

Why are interlocks used?

To avoid unsafe actions, protect equipment, and ensure operators follow safe sequences.

What types of interlocks exist?

Mechanical, electrical, electronic/PLC-based, and process-condition interlocks.

Where are interlocks commonly used?

In machinery guards, motor controls, breakers, process plants, elevators, and home appliances.

How does an interlock work?

It checks a condition (sensor, switch, status) and allows or blocks an action based on safety rules.

What happens if the condition is not met?

The interlock blocks the action and keeps the system in a safe state.

Can interlocks be bypassed?

Yes, if poorly designed. Modern standards require designs that reduce the chance of bypassing.

What standards apply to interlocks?

Common ones include ISO 14119 and related machine-safety standards.

Are interlocks part of protection systems?

Yes, they help prevent unsafe states before they occur.

Do PLCs use interlocks?

Yes. PLCs often implement interlock logic for complex sequences and machine safety.