Temperature is a basic physical quantity measured and controlled in almost every field. From managing home climate systems to handling complex chemical reactions, temperature sensors play a key role in safety, efficiency, and quality.

They work by converting heat energy into an electrical signal that can be interpreted. The range of available sensors can seem vast.

Nevertheless, knowing their main principles, pros, and limits helps in selecting the right one.

This article explores the most common types of temperature sensors, detailing how they function and where they are best applied. It also details of how to choose them and what their trending future.

Contact vs. non-contact sensing

Temperature sensors fall into two main groups: contact and non-contact. Contact types, such as thermocouples, thermistors and RTDs need to touch the object or medium they measure.

They sense their own temperature, assumed to match the target once thermal balance is reached.

On the other hand, non-contact sensors, like infrared thermometers, detect temperature remotely by reading the infrared energy emitted by an object.

Contact sensors

This section talks about the contact sensors.

Thermocouples

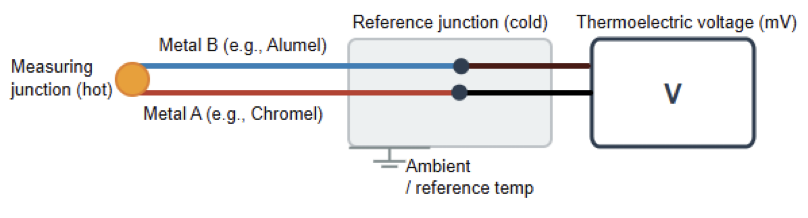

A thermocouple uses two different metal wires joined at one end. It works on the Seebeck effect.

The latter states that a voltage appears between two conductors when there is a temperature difference.

The magnitude of the voltage depends on the temperature difference between the measuring and reference junctions.

Working principle of thermocouples

When the junction of both metals is heated or cooled, a small thermoelectric voltage is produced.

This signal, in millivolts, must be read and converted to temperature. For accuracy, the reference junction temperature must be known and compensated for.

Modern devices do this electronically. The figure below illustrates a simple diagram of a thermocouple circuit showing the hot (measuring) junction and the cold (reference) junction connected to a voltmeter.

Types of thermocouples

Thermocouples are classified by material, which defines their range and traits. Common examples include:

• Type K: Chromel-Alumel, general-purpose, wide range.

• Type J: Iron-Constantan, common but narrower range.

• Type T: Copper-Constantan, good for humid or cryogenic use.

• Noble types (R, S, B): Made with platinum and rhodium for very high temperatures.

Thermistors

Thermistors are temperature-sensitive resistors made from semiconducting oxides. Unlike RTDs, they show a large, non-linear resistance change with temperature.

Working principle of thermistors

Two main kinds exist:

• Negative Temperature Coefficient (NTC): Resistance drops as temperature rises. Used for sensing. See the next figure.

• Positive Temperature Coefficient (PTC): Resistance increases with temperature. Used as resettable fuses or heaters.

Linearization

Because their response is highly non-linear, thermistors must be linearized to get precise temperatures. This is done using circuits or software, often through the Steinhart-Hart equation.

Advantages and disadvantages

Thermistors are very sensitive, quick to respond, and inexpensive. Their drawbacks are a limited range and fragility compared to thermocouples.

Resistance Temperature Detectors (RTDs)

RTDs measure temperature by tracking the resistance change of a metal. Platinum is the most common element due to its stable, repeatable behavior.

Nickel and copper are also used. As temperature rises, resistance increases in a nearly straight line.

Working principle of RTDs

An RTD passes a small constant current through the platinum element. The voltage drop is measured and converted to temperature using a calibration curve. A Pt100 RTD has 100 Ω at 0°C.

Construction

RTDs are built in several forms:

• Wire-wound: Metal wire wrapped on a core and sealed. Precise but costly.

• Thin-film: A thin platinum layer on a ceramic base. Smaller, faster, and cheaper.

• Coiled element: A small coil placed in a ceramic form, allowing expansion and high accuracy.

The figure below indicates a diagram illustrating the construction of a thin-film RTD, showing the ceramic substrate and the thin platinum path (meander).

Wiring configurations

RTDs use wiring setups to correct for lead resistance:

• 2-wire: Simplest, least accurate.

• 3-wire: Most used, compensates for lead resistance.

• 4-wire: Most accurate, fully cancels lead effects.

RTD vs. thermocouple

Generally, RTDs are more accurate and stable than thermocouples. Nevertheless, they have a narrower temperature range and slower response time. In addition, they are more expensive due to the use of platinum.

Bimetallic strip thermometers

Bimetallic thermometers rely on thermal expansion. A strip of two metals with different expansion rates bends when heated.

Working principle

One end is fixed while the other moves. As temperature shifts, the bend moves a pointer on a dial.

This simple and strong design is used in thermostats and dial thermometers. The following figure depicts a diagram showing a bimetallic strip bending when heated.

Notice that the metal with the higher expansion rate is on the outside of the curve.

Variations

To save space and increase sensitivity, the strip can be wound into a coil. This adds length and boosts movement and response.

Non-contact sensors

This section explains the non-contact sensors.

Infrared sensors

Infrared or pyrometric sensors measure temperature without touching the object. They sense the infrared radiation emitted by a surface.

Working principle of infrared sensors

Anything above absolute zero emits infrared energy. The sensor focuses this radiation onto a detector, often a thermopile. The detector converts it into an electric signal and shows the temperature.

Factors affecting accuracy

Accuracy depends on emissivity, a surface’s ability to emit radiation. Shiny materials have low emissivity and may cause errors. Some sensors allow emissivity adjustment to correct for this.

Advantages and disadvantages

Infrared sensors are great for moving, hot, or unsafe targets. They react fast and stay clean. Their limits include sensitivity to surface finish and ambient conditions.

Semiconductor-based sensors

Semiconductor temperature sensors are ICs that use the temperature-dependent traits of semiconductors. They are widely used in electronics for monitoring.

Working principle

Most use the voltage drop across a diode junction. By running two transistors at different current levels, the voltage difference shows absolute temperature. This is converted into a linear output.

Digital vs. analog output

They can output digital or analog signals. Digital types send direct readings via I²C or SPI. Analog versions give a voltage or current proportional to temperature.

Limitations

They are cheap and easy to integrate but have limited range and lower accuracy than thermocouples or RTDs. Response time can also be slower.

Choosing the right sensor for your application

Selecting a temperature sensor depends on several factors:

• Temperature range: Match the sensor’s range to expected conditions. Thermocouples suit extreme ranges; RTDs and thermistors fit moderate ones.

• Accuracy: RTDs and thermistors are more accurate within their ranges.

• Response time: Thermistors and thermocouples respond faster. Infrared sensors give instant readings.

• Durability: Thermocouples are rugged; thermistors are delicate.

• Cost: Thermistors are cheapest, RTDs are priciest, and semiconductor sensors balance cost and performance.

• Environment: Check for vibration, corrosion, and harsh conditions. Noble thermocouples resist heat and corrosion well.

The Future of Temperature Sensor

The future of temperature sensors is moving toward higher precision and smaller size. Wireless technology and non-contact methods are becoming more common.

New materials like graphene and other carbon-based nanomaterials will make sensors more flexible and sensitive.

Advances in digital signal processing will boost accuracy and automation. The market will grow rapidly, driven by demand from healthcare, industrial automation, and the Internet of Things (IoT).

Key takeaways: Temperature Sensor Types

This article showed the study of the different types, working principles, and uses of temperature sensors, how to choose, and their future.

It further proved that temperature sensors are vital for precise control and monitoring in many systems.

The right choice depends on needs like range, accuracy, speed, toughness, and cost. Knowing how each sensor works, from thermocouples and thermistors to RTDs and infrared types helps ensure performance and reliability.

Semiconductor sensors have added compact, low-cost options for electronics, widening the range of choices.

As technology evolves, temperature sensing remains key to progress and innovation.

FAQ: Temperature Sensor Types

What are the main types of temperature sensors?

The main types include:

- Thermocouple — two dissimilar metals producing a voltage.

- RTD (Resistance Temperature Detector) — metal resistance changes with temperature.

- Thermistor — semiconductor/metal-oxide resistor with large change in resistance.

- Semiconductor temperature sensor — integrated circuits using diodes or transistors.

- Infrared (noncontact) sensor — measures infrared radiation emitted by an object.

Why are there so many different types of temperature sensors?

Because different applications have different needs for: temperature range, accuracy, response time, environmental durability, contact vs non-contact measurement.

When should I use a thermocouple?

Use a thermocouple when you need a wide temperature range (including high extremes), ruggedness or minimal cost. They are less accurate but very versatile.

When is an RTD a better choice?

An RTD is better when you need higher accuracy, better stability and repeatability, and you operate in moderate temperature ranges.

What are the advantages and limitations of a thermistor?

Advantages: very high sensitivity in a narrow range, cost-effective. Limitations: nonlinear behavior, limited high-temperature range, more complex conversion.

What is a semiconductor temperature sensor and where is it used?

It is often an IC that uses temperature-sensitive voltage/current behavior of semiconductors. Used for integrated electronics, moderate temperature ranges, lower cost.

What is a non-contact (infrared) temperature sensor and when would I use it?

A non-contact sensor detects infrared radiation from an object’s surface, so it can measure without touching the object. Use it for moving, hazardous, or inaccessible targets.

How do I choose the right temperature sensor for my application?

Consider: temperature range, accuracy required, response time, durability/environment, cost, and whether contact or non-contact measurement is needed.

What is the difference between contact and non-contact temperature sensors?

Contact sensors must physically touch the object (e.g., thermocouples, RTDs). Non-contact sensors measure from a distance via emitted radiation (e.g., infrared).