A star-delta starter, also known as a Wye-Delta starter, is a popular way of reduced-voltage motor starter.

It is especially helpful when the objective is to reduce the high inrush current. This current appears during direct-on-line starting.

Instead of applying full line voltage immediately, the motor begins in a star connection. This lowers the voltage across each winding, and it limits the current. After the motor reaches a certain speed, the connection shifts to delta.

This allows the motor to run at its full rated power. The technique is reliable, cost-effective, and simple.

It is also widely used in many industrial applications. This article studies what a star-delta starter is, why it is used, and how it works in real industrial settings.

The Basic Idea

The star-delta starter is built around one main idea. The goal is to start a motor at reduced voltage to limit the mechanical and electrical stress that naturally occurs during startup.

When a motor starts, the rotor is stationary, and this causes the stator to experience very low impedance.

This results in extremely high starting current. By beginning in a star connection, each winding receives a lower phase voltage.

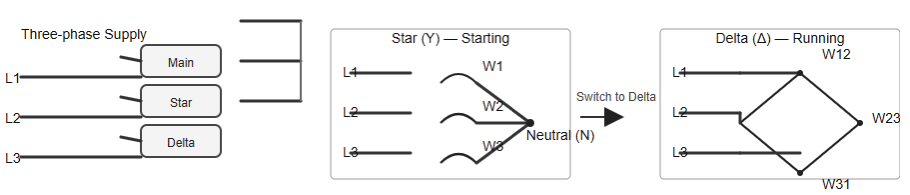

This keeps the current under control. It still provides enough torque to begin acceleration. The following figure shows a simplified schematic illustrating star and delta connections.

The Need for Reduced-Voltage Starting

Induction motors can draw six to eight times their rated current during startup. This surge only lasts a few seconds. However, it can cause voltage dips, light flickering, and tripping of protection devices.

Many electrical networks cannot handle this sudden load comfortably. The issue becomes worse when several machines share the same supply. Reduced-voltage starting methods like star-delta help the motor begin more gently.

They do this by lowering the current drawn from the grid during the first seconds of operation.

For loads such as fans and pumps, the reduced starting torque is still enough to set the rotor in motion. Similar situation when it comes to blowers.

Star Connection

Another option is a star connection. When a motor is connected in a star, the ends of its three windings are tied together at a single neutral point.

The other ends are connected to the three-phase supply. Because of this configuration, each winding receives line voltage divided by √3.

This arrangement significantly reduces the applied voltage. Lower voltage results in lower current. It also reduces the torque produced.

However, the motor still produces enough torque for light to medium loads. This is why the star connection is ideal for the initial acceleration phase.

Delta Connection

Once the motor accelerates to around 70–80% of its rated speed, it is ready for full voltage.

It then receives full line voltage through a delta connection. In this mode, each winding is linked between two phases.

This allows the motor to deliver its rated torque and power. The shift from star to delta is automatic.

It is controlled by the starter’s timing system. Delta is the normal running mode for most industrial motors.

Switching Mechanism

A star-delta starter uses three contactors. These are the main contractor, the star contactor, and the delta contactor.

When the operator presses START, the main and star contactors close. This connects the motor windings in a star.

A timer begins counting. It allows the motor to accelerate under reduced voltage. After the preset time expires, the star contactor opens. Then the delta contactor closes.

This completes the transition to full voltage. Interlocks ensure the star and delta contactors never engage at the same time. They prevent short circuits and equipment damage.

Sequence of Operation

The operation follows a predictable sequence. First, the main contactor energizes. This supplies power to the motor.

Immediately afterward, the star contactor closes. The motor begins in the star configuration with reduced voltage.

During this period, the motor gains speed gradually. When the timer finishes its delay, the star contactor drops out.

A short safety pause follows. Thereafter, the delta contactor closes. The motor then runs at full line voltage.

The switching must be precisely timed. Incorrect timing may produce torque shocks or transition problems.

Components of Star-Delta Starter

A complete starter contains several critical components. The main, star, and delta contactors carry the load and switch the windings. The overload relay protects the motor from excessive running current.

The timer controls the delay before switching. Interlocks prevent simultaneous engagement.

Additional components, such as control relays and auxiliary contacts, support the control logic.

A control transformer may also be included when needed. The following figure indicates a start-delta panel layout.

Why Interlocking Is Essential

Interlocking prevents dangerous overlap between the star and delta contactors. Mechanical interlocking uses a physical mechanism. It blocks one contactor when the other is active. Electrical interlocking uses auxiliary contacts.

They break or allow coil current depending on the state of the opposite contactor. Without interlocking, both contactors could close at the same time.

The process would create a phase-to-phase short. Such a short could destroy the contactors. It could also damage the motor.

Advantages of Using a Star-Delta Starter

Star-delta starters offer several strong benefits. They significantly lower the starting current. They also reduce mechanical stress on the motor shaft and bearings. Voltage drops in the electrical supply are minimized.

This helps stabilize the grid. The design is simple and inexpensive. It is cheaper than soft starters or VFDs. Maintenance is straightforward because most parts are electromechanical.

The figure below depicts the comparison of DOL, star-delta, and VFD in terms of costs.

Limitations and Downsides

Despite the advantages, the star-delta method has limitations. It provides only one fixed level of voltage reduction. The transition between star and delta is abrupt. This can create torque spikes.

Reduced starting torque makes the method unsuitable for heavy loads. Motors must also have six accessible terminals. Not all motors are built this way.

The method is not ideal when frequent starts are required. Contactors will wear out faster under those conditions.

Applications of Star-Delta

Star-delta starters are the best fit for loads that can accelerate easily under reduced torque.

Common examples include fans, centrifugal pumps, blowers, and compressors. Long conveyors with low friction also fit this category.

These loads do not need high initial torque. The reduced torque in star mode is still enough to start them. For heavy loads such as crushers or hoists, other starting methods are required.

Requirements for Star-Delta Operation

A star-delta starter requires a motor designed for delta operation at the supply voltage. It must also provide access to all six winding terminals.

Motors labeled “400V Delta / 690V Star” are usually a perfect fit for electrical systems running at 400 volts.

A vast number of motors consist of only three terminals. These cannot be switched externally.

Their internal winding configuration cannot be changed. Choosing the correct motor is essential.

The Transition Challenge

One drawback of the star-delta method is the momentary disconnection during switching. This short interruption can cause a current spike. It can also cause a torque dip. Engineers must select the transition delay carefully.

The motor must reach enough speed in star mode. Poor timing can lead to stress, voltage spikes, or even motor stalling.

Star-Delta vs Soft Starters

Soft starters use solid-state devices to ramp voltage smoothly. They offer controlled acceleration.

They avoid the mechanical and electrical shocks seen in star-delta transitions. Their settings are adjustable.

However, they cost more. They also require cooling because they generate heat. Star-delta is still attractive for simple and low-cost installations.

Star-Delta vs Variable-Frequency Drives

Variable-Frequency Drives (VFDs) offer the most advanced motor control. They adjust both voltage and frequency.

This method provides full torque even at low speeds. They provide soft start, speed control, protection, and energy savings.

The disadvantages are cost, complexity, and harmonics. Star-delta remains useful where speed control is not required. It is simple, rugged, and economical.

Panel Layout and Wiring Considerations

A star-delta panel is organized to keep components accessible. The main contactor is usually placed in the center.

The star and delta contactors are mounted beside it. The overload relay sits below the main contactor.

The timer is installed in the control wiring section. Good cable routing and labeling reduce errors. They also speed up maintenance.

Maintenance and Troubleshooting

Star-delta starters need periodic inspection. Contactors should be checked for wear or pitting.

Coils should be tested for proper operation. The timer must be verified to ensure the correct delay. Overload relays should be inspected and reset if necessary.

When faults occur, technicians often begin by checking the contactor sequence. Incorrect sequencing causes most failures.

Modern Enhancements and Hybrid Designs

Modern star-delta systems may include electronic timing modules. These provide more precise control.

Some designs combine electromechanical and solid-state components. This hybrid approach smooths the transition between star and delta.

It reduces mechanical wear. It also lowers electrical stress. Some systems include advanced protection and communication features. Such functionality makes them more suitable for modern automation environments.

Conclusion

This article reviewed the principles, components, operation sequence, applications, and limitations of the star-delta starter.

A star-delta starter remains a practical and trusted solution for many industries. It is simple. It is affordable.

And it is effective in reducing the starting current of three-phase motors. The method uses a star connection during startup.

This practice reduces voltage. It also reduces inrush current. After the motor accelerates, the system changes to delta.

Then the motor receives full line voltage. This allows the motor to deliver full torque and operate at its rated condition.

The approach works well when loads are light or medium during startup. It is also ideal when budgets are limited.

However, star-delta starters are not perfect. They create a momentary torque dip during transition.

They also do not offer smooth acceleration like modern electronic starters. Even so, the technique remains popular. Its reliability keeps it relevant.

Its low cost makes it attractive. Its simplicity guarantees its long-term use in numerous systems.

FAQ: What is a Star-Delta Starter, and How Does it Work?

What is a Star-Delta Starter?

A Star-Delta Starter is a reduced-voltage motor starter that starts in star mode and then transitions to delta mode.

Why is it used?

To cut down the high inrush current during motor startup.

How does it work?

The motor starts in star mode, accelerates, and then the timer switches it to delta mode.

What happens in star mode?

The motor receives reduced voltage and torque.

What happens in delta mode?

Motor receives full voltage and runs at rated power.

What are the advantages?

The advantages include a lower starting current, reduced stress, simplicity, and affordability.

What are the disadvantages?

The disadvantages include a low starting torque and a brief torque dip during the transition.

What components does it use?

It utilizes three contactors, a timer, and an overload relay.

When should it be used?

For motors with light or medium startup loads.

When shouldn’t it be used?

It should not be used for heavy loads or high-torque startup applications.

Does every motor support star-delta?

No. Only motors with six accessible terminals.

Is it better than a VFD?

No. VFD gives better control but costs more.