A PLC (Programmable Logic Controller) programmer is a professional in industrial automation.

They design, program, and maintain the rugged computers that control machines and manufacturing systems.

Their work is key to the smooth and reliable operation of modern industries. This article explains the role, skills, tools, and future of PLC programmers in automation. PLC programmers combine electrical, mechanical, and software knowledge.

They create the logic that automates everything from conveyor systems to chemical processing plants. Their goal is to make machines run efficiently, safely, and predictably.

This article explains how PLC programmers serve as the link between engineering and digital control.

It describes how they use programming logic to transform manual operations into automated processes that enhance productivity and safety.

It also highlights their importance in ensuring that industrial systems communicate effectively, adapt to new technologies, and maintain consistent performance in demanding environments.

The Role of a PLC Programmer

A PLC programmer develops the software that defines how machines behave. They transform operational requirements into automated logic.

This work supports many industries such as automotive, food, packaging, and energy.

Key responsibilities include:

Assessing client requirements

They meet with engineers and plant managers to define how a process should operate. This includes setting sequences, safety logic, and expected machine actions.

Designing and writing programs

They use specialized languages to build control logic that tells the PLC how to react to sensor inputs and control outputs like motors or valves.

Creating schematics

They interpret or produce diagrams that show wiring and component interaction. These documents are vital for programming, troubleshooting, and maintenance.

Testing and commissioning

They debug and test code to confirm that systems work correctly. This often involves on-site startup and validation of performance.

Providing support and maintenance

They handle software and hardware issues after installation. They also modify programs to improve performance or fit new production needs.

How a PLC Works

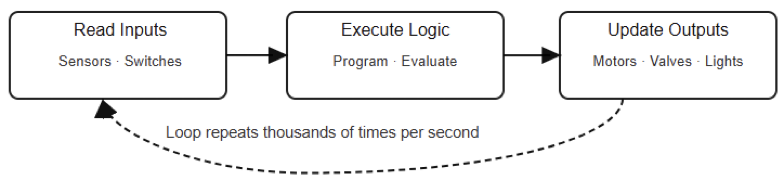

A PLC operates through a continuous scan cycle, which repeats thousands of times per second. Understanding this process is essential for every programmer.

The cycle includes three main steps:

- Read Inputs: The PLC checks all input devices, such as sensors or switches, and stores their status in memory.

- Execute Logic: It runs the program line by line to decide what outputs should activate.

- Update Outputs: The PLC sends signals to devices like motors or lights according to the results of the logic.

This rapid process creates real-time, reliable control of industrial systems. The figure below indicates a simplified PLC Scan Cycle showing “Read Inputs – Execute Logic – Update Outputs and Loop back.

The Languages of PLC Programming

The IEC 61131-3 standard defines five major PLC programming languages. Each one suits different types of applications.

While Ladder Logic remains the most familiar, others are becoming more common as systems grow more complex.

The five standard languages are:

Ladder Logic (LD)

A visual, easy-to-read language that looks like relay circuits. It is popular among electricians and ideal for sequential control.

Structured Text (ST)

A high-level text language similar to C or Pascal, good for math and data handling.

Function Block Diagram (FBD)

A graphical language using blocks connected by lines to represent signal flow. It’s often used in process industries.

Instruction List (IL)

A low-level, assembly-like language. It is less used today but still useful for optimizing performance.

Sequential Function Chart (SFC)

A graphical method to organize processes into steps and transitions, helpful for machines with defined sequences.

The next figure indicates examples of PLC Programming Languages, showing Ladder Logic, Structured Text, and Function Block Diagram.

Essential Skills for a PLC Programmer

A successful PLC programmer needs both technical and soft skills.

Technical skills include:

- Strong knowledge of at least one major PLC brand, such as Siemens, Allen-Bradley, or Schneider Electric.

- The ability to read and design electrical diagrams and understand control systems.

- Experience with HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) systems for operator interaction and data logging.

- Familiarity with communication networks like Modbus, Profibus, and Ethernet/IP.

- Understanding of hardware elements such as CPUs, I/O modules, and power supplies.

Soft skills include:

- Problem-solving: The ability to detect and fix complex faults quickly.

- Attention to detail: Even a minor error in logic can stop production.

- Communication: Clear interaction with engineers, operators, and managers.

- Adaptability: Staying current with evolving automation tools and techniques.

The Path to Becoming a PLC Programmer

There are several ways to enter this field, combining education and hands-on learning.

- Education: A degree or diploma in electrical or mechanical engineering helps. Many technical schools offer automation-focused programs.

- Experience: Real-world practice is essential. Internships, co-op training, or personal PLC projects provide valuable exposure.

- Certification: Credentials from companies like Rockwell or Siemens enhance credibility.

- Continuous learning: The technology evolves rapidly, so keeping up with updates, software tools, and new industry standards is vital.

The Future of PLC Programming

The world of automation is advancing quickly, and PLC programmers are adapting to new trends.

- Integration with IoT: PLCs are now part of larger networks through the Industrial Internet of Things (IIoT), improving monitoring and control.

- Industry 4.0: Smart factories depend on connected PLCs that enable autonomous decision-making.

- Cybersecurity: With greater connectivity comes the need for stronger protection against cyber threats.

- Artificial Intelligence and Machine Learning: These technologies will improve predictive maintenance and product quality.

- Wireless communication: Reduces wiring and increases flexibility in system design.

- User-friendly interfaces: Modern tools make programming more intuitive for engineers of different backgrounds.

Key Takeaways: What is a PLC Programmer?

This article explored PLC programmers as the driving force behind modern automation.

It examined their crucial role in designing, coding, and maintaining control systems that keep industrial processes running smoothly.

By integrating engineering principles with advanced software, PLC programmers ensure that automated operations remain efficient, adaptable, and safe. Hence, the work of a PLC programmer is essential to modern industry.

They convert operational needs into logical instructions that control automation systems with accuracy and safety.

Their mastery of programming languages and new technologies keeps production efficient and reliable.

As factories evolve toward smarter, connected systems, the role of PLC programmers continues to grow in importance.

They are the unseen force behind every automated process, ensuring precision, safety, and progress.

This article explored the key functions, tools, and future trends shaping the profession of PLC programming.

FAQ: What is a PLC Programmer?

What does a PLC Programmer do?

They design, write, test, and maintain software for programmable logic controllers in industrial settings.

What skills are needed to be a PLC Programmer?

Technical: programming languages like Ladder Logic, Structured Text; electrical/control systems; safety and hardware knowledge.

Soft: problem-solving, detail orientation, communication, adaptability.

What kind of education or training is required?

Often a degree or diploma in electrical, mechanical, automation, or related engineering field. Vocational training and PLC-specific certifications help.

Where do PLC Programmers work?

Factories, plants, industrial automation firms, system integrators. Also, in sectors like food & beverage, pharmaceuticals, energy, water treatment.

Why are PLC Programmers important?

They automate processes, reduce human error, ensure safety, improve efficiency, reduce downtime.

What tools/software do they use?

PLC programming software (Siemens STEP 7, Allen-Bradley RSLogix etc.), simulation tools, diagnostic and communication modules.

How does one advance in this career?

Gain experience, take on larger and more complex projects, get certified, stay updated with new technologies like Industry 4.0, IoT.