Programmable Logic Controllers (PLCs) are the brains of modern conveyor systems, replacing older, bulky relay logic that once dominated industrial automation.

Unlike simple relay panels, a PLC is a robust industrial computer that uses a customizable program to monitor inputs and control outputs, enabling precise, repeatable, and efficient automation.

From simple start-and-stop operations to complex sorting, counting, and product tracking, PLCs offer a reliable, flexible, and scalable solution for material handling across different industries.

Conveyor systems powered by PLCs are now found in manufacturing, warehousing, mining, logistics, food processing, and packaging plants.

Their adaptability ensures they can handle everything from light consumer goods to heavy industrial components.

This article explains the role of PLCs in conveyor, the core components for PLC to drive conveyors and PLC operation cycle.

It further details how to program a conveyor, the benefits of PLC controlled conveyors and the future of PLC in conveyors.

The Evolution of Conveyor Control

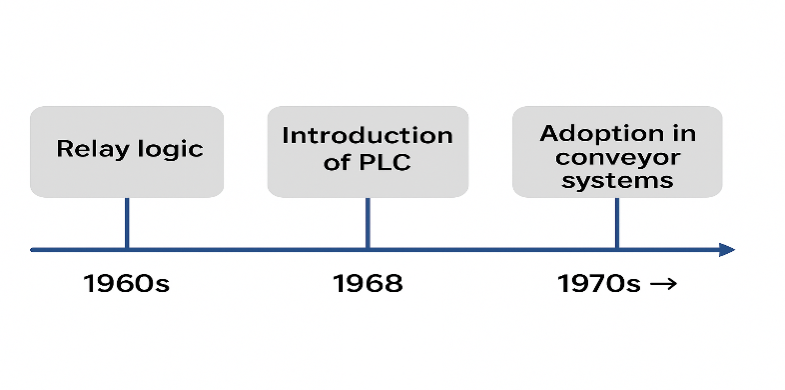

Before PLCs, conveyor systems were controlled by complex arrangements of relays, contactors, and timers.

This hardwired relay logic was not only bulky but also prone to frequent failure due to worn contacts, dust accumulation, or overheating.

It was incredibly difficult to modify or troubleshoot, especially when hundreds of relays were wired together in large panels.

Changing an operation or adding a new feature required extensive rewiring, which often led to long and costly periods of downtime.

The invention of the PLC in the late 1960s revolutionized industrial control. By using a software-based program, manufacturers could change or replicate operations simply by reprogramming the PLC, drastically reducing time and engineering costs.

PLCs brought unprecedented flexibility, faster troubleshooting, and greater reliability to conveyor control.

What once took days of rewiring could now be accomplished in minutes with a simple logic change.

The Core Components of a PLC-Driven Conveyor System

A PLC-controlled conveyor system relies on a seamless interaction between several components that work together as a closed-loop control system.

PLC Unit

The central processor runs the control program. It executes logic instructions, makes decisions based on input data, and sends commands to output devices.

Modern PLCs also support communication protocols like Ethernet/IP or Modbus for integration with higher-level systems.

Sensors

These devices provide real-time information to the PLC. Common types used in conveyors include:

Photoelectric sensors

Use a beam of light to detect the presence or absence of a product on the belt, widely used in packaging lines.

Proximity sensors

Detect objects without physical contact. Inductive models sense metals, while capacitive models can detect both metallic and non-metallic items like plastic or glass.

Limit switches

Triggered by physical contact with a product or diverter arm, often used in positioning.

Encoders

Measure the rotational speed and angular position of conveyor rollers, enabling precise control of product movement.

Load cells

Weigh items on the conveyor belt, ensuring quality control or accurate batching.

Motors and Variable Frequency Drives (VFDs)

An electric motor powers the conveyor belt. VFDs are often used to control the motor’s speed, allowing for smooth acceleration, controlled deceleration, energy savings, and precise speed adjustments during different stages of production.

Actuators

Devices that perform physical actions, controlled by the PLC. Examples include pneumatic cylinders for pushing or sorting products, solenoid valves for directing compressed air, or stepper motors for precision positioning in automated assembly lines.

Human-Machine Interface (HMI)

A touchscreen or display panel that allows operators to monitor the system’s status.

Operators can adjust conveyor speed, acknowledge alarms, view production statistics, and switch between manual or automatic modes.

Safety Devices

Components like emergency stop buttons, safety pull cords along conveyor lines, and safety gates are wired to the PLC to ensure safe operation.

Modern systems may use a dedicated Safety PLC or safety relays for critical functions, meeting international safety standards such as ISO 13849 or IEC 61508.

The PLC Operational Cycle

The PLC operates in a continuous loop called a scan cycle, which ensures fast and consistent responses to changing system conditions.

Input Scan

The PLC checks the status of all input devices, such as sensors, push buttons, and switches. This data is stored in memory for processing.

Program Execution

The PLC runs its stored program logic line by line. It processes the input data and makes logical decisions based on the defined instructions.

Output Scan

The PLC updates the status of all output devices, such as motors, actuators, and indicator lights, according to the program’s decisions.

Housekeeping

The PLC performs internal tasks such as communication with other PLCs, diagnostic checks, and self-monitoring.

This rapid, repetitive process enables real-time control of the conveyor system, with scan times often measured in milliseconds.

Programming a Basic Conveyor System

PLC programming languages have evolved over time to make system development easier and more powerful.

The most common is Ladder Logic, a graphical language that mimics the appearance of a relay logic diagram, making it easy for electricians and engineers to understand.

Other languages include Function Block Diagram (FBD) for modular design, Structured Text (ST) for advanced algorithms, and Sequential Function Chart (SFC) for step-by-step processes.

A simple “start-stop” conveyor system illustrates basic PLC programming principles:

- A normally open (NO) start button is wired to a digital input on the PLC.

- A normally closed (NC) stop button is wired to another digital input.

- The conveyor motor starter is wired to a digital output.

- The Ladder Logic program has a “rung” that latches the motor starter on when the start button is pressed. The motor is de-energized if the stop button is pressed or if a safety interlock is activated.

This simple design ensures reliable operation while protecting the conveyor from accidental restarts.

Advanced PLC Control Applications

Modern conveyor systems go far beyond simple start-stop functions, thanks to the flexibility and power of PLCs.

Automated Sorting

The PLC can use input from sensors, barcode scanners, or vision systems to direct products to different lanes.

In a waste sorting system, an AI-driven camera can identify recyclable materials, and the PLC can activate a diverter arm or air jet to push the product into the correct bin.

Variable Speed Control

By controlling a VFD, the PLC can adjust conveyor speed in real time. This is crucial for synchronizing multiple conveyor sections or for precise positioning of products before packaging or labeling.

Robotic Integration

In automated assembly lines, the PLC coordinates conveyor movement with robotic arms.

It ensures products arrive at the correct pick-up points exactly when the robot is ready.

Tracking and Monitoring

Using encoders, load cells, and RFID tags, the PLC can track products along the conveyor.

This enables functions such as product counting, batch control, weight verification, or rejection of defective items.

Predictive Maintenance

PLCs can collect vibration, temperature, and current data from motors and sensors to monitor equipment health.

This allows maintenance teams to anticipate failures before they occur, significantly reducing unexpected downtime.

Networking and SCADA Integration

Multiple PLCs can communicate with each other over industrial networks. They can also send data to a higher-level SCADA (Supervisory Control and Data Acquisition) system for plant-wide monitoring and decision-making.

The Benefits of PLC-Controlled Conveyors

The adoption of PLC technology offers a wide range of advantages over older relay-based methods.

Increased Efficiency and Throughput

PLCs operate with high speed and precision, minimizing errors, reducing downtime, and maximizing the number of products moved per hour.

Enhanced Flexibility and Scalability

PLCs can be reprogrammed quickly to accommodate new product lines or processes. Modular PLCs allow for easy expansion by adding additional I/O modules.

Improved Safety

PLCs can be integrated with safety interlocks, light curtains, emergency stops, and safety relays to ensure worker protection and prevent equipment damage.

Reduced Operational Costs

Automation reduces the need for manual labor, while simplified troubleshooting, remote monitoring, and predictive maintenance cut maintenance costs.

Better Data Collection and Analysis

PLCs provide valuable production and diagnostic data that can be used for process optimization, quality assurance, and continuous improvement.

Future Trends

The role of PLCs in conveyor systems continues to evolve with modern digital technologies.

Integration with AI

As seen in waste sorting and logistics, AI-driven vision systems are being integrated with PLCs to enhance accuracy and efficiency.

Edge Computing

PLCs with built-in edge computing capabilities can process large amounts of data locally, reducing latency and enabling smarter decision-making on the factory floor.

Enhanced Cybersecurity

As PLCs become more connected to networks and cloud platforms, cybersecurity is a growing priority.

Future systems will feature secure communication protocols, firewalls, and multi-level authentication.

Digital Twins

The PLC can be linked to a digital twin—a virtual model of the conveyor system. This allows engineers to test, simulate, and optimize control strategies before deploying them in the real world.

Conclusion

The present article detailed the role of PLCs in conveyor, the core components for PLC to drive conveyors and PLC operation cycle.

It also explained how to program a conveyor, the benefits of PLC controlled conveyors and the future of PLC in conveyors.

So, from the discussion we can add that, PLs have fundamentally transformed how conveyor systems operate.

They have replaced outdated relay logic with flexible, reliable, and powerful software-based control.

From managing simple belt movement to orchestrating complex sorting, tracking, and predictive maintenance, PLCs are at the heart of modern material handling.

Their ability to increase efficiency, enhance safety, and adapt to changing production requirements makes them an indispensable part of industrial automation.

As technology continues to advance, the integration of PLCs with AI, edge computing, and digital twins will drive even greater innovation in conveyor systems, ensuring smarter, faster, and safer factories for the future.

FAQ: PLC in Conveyor Systems

What are the advantages of using a PLC instead of traditional relay‐logic for conveyor control?

PLCs offer much more flexibility: logic can be changed, expanded or replicated via software rather than rewiring; They provide real‐time monitoring, diagnostics, and improved safety (interlocks, emergency stops) that relay systems typically lack or have in more complex/harder to maintain arrangements; PLCs can integrate better with modern systems (HMI, SCADA, cloud/edge computing) to enable remote monitoring and predictive maintenance.

What PLC programming languages are common, and which are best for conveyors?

The IEC 61131-3 standard defines several languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Sequential Function Chart (SFC), and Instruction List (IL); For many conveyor systems, Ladder Logic (LD) is often preferred since it’s intuitive for relay logic designers and maintenance staff; For more complex sequencing, tracking, or mathematical/logical processing, Structured Text (ST) or Function Block Diagram might be used.

How is PLC integrated with sensors, actuators, and other devices in a conveyor system?

Sensors (photoelectric, proximity, load cells, encoders, etc.) feed inputs to the PLC.

The PLC reads these sensors during its input scan to decide when to activate outputs; Outputs from the PLC can command motors (via starters or VFDs), actuators, indicator lights, diverters, gates, etc; Safety devices (emergency stops, safety gates) are usually wired in, sometimes via a safety PLC or safety-rated modules.

What kind of PLC scan cycle or timing issues affect conveyor systems?

The scan cycle is the core loop in which the PLC reads inputs, executes the user program logic, updates outputs, and performs internal housekeeping.

If the cycle time is too long, fast events (e.g. high‐speed sensors detecting an object) may be missed or delayed; Conveyor systems with high speed, lots of sensors and tight timing (for accurate stopping, diverter activation, etc.), require careful tuning of scan time and priority of tasks.

Can I use a single PLC for large conveyor systems, or do I need multiple PLCs?

In many systems, a single PLC is sufficient to manage a conveyor system, especially if the system is not extremely large or complex; Multiple PLCs are used when there are modular sections that are physically distant, for redundancy, easier maintenance, or when different subsystems need different performance or I/O counts.

What safety features are necessary when using PLCs in conveyor systems?

Emergency‐stop buttons, safety pull cords, safety gates, and interlock switches must be integrated.

These should be wired such that they override other logic; Safety PLCs or safety modules are used for functions where failure could seriously risk personnel or equipment. These are designed to standard safety categories/PL/SL levels.

How do PLCs handle varying conveyor speeds or synchronization between conveyor sections?

Variable Frequency Drives (VFDs) are often controlled by the PLC, allowing precise acceleration, deceleration, and speed synchronization; PLC logic may coordinate multiple sections so products transfer smoothly from one section to another without collisions or excessive gaps.

What is predictive maintenance in the context of PLC‐controlled conveyors, and how is it done?

PLCs can collect data: motor currents, vibration (if sensors added), runtime, number of starts/stops, errors; This data can be analyzed (locally or via cloud/edge) to predict component wear, detect abnormal behavior, and schedule maintenance before failures.

What are common problems people face when implementing PLCs on conveyors?

Underspecified sensors or choosing sensors that don’t suit the environment (e.g. dust, moisture, high vibration); Delays or errors due to poor logic timing or scan cycle too slow; Synchronization problems between conveyor sections, especially during changes in direction or speed; Safety interlocks not properly designed or tested, leading to false trips or unsafe behavior; Insufficient diagnostics or logging, making troubleshooting difficult.

How do costs compare (initial, maintenance, operational) when using PLCs vs older relay logic?

Upfront cost of PLC hardware (CPU, I/O modules, power supply), plus programming, integration, sometimes network/HMI/SCADA setup is higher than simple relay panels; But lifecycle cost savings tend to be significant: lower maintenance, easier upgrades, less downtime, more efficient operation.

How do I choose the right PLC size or model for my conveyor system?

Consider number of inputs/outputs needed (digital, analog), size/complexity of logic, speed requirements; Environmental factors: temperature, dust, moisture, electrical noise; Require capacity for expansion or extra features (networking, safety I/O, vision/camera input) if future growth is expected.

How is PLC connected/interfaced with modern technologies (vision systems, cloud, digital twins)?

PLCs can receive input from vision systems / barcode scanners / AI systems; process or forward that data to make decisions (e.g., diverters, reject stations);

Connectivity to edge/cloud allows remote monitoring, analytics, and model‐based control; Digital Twins (virtual models) can mirror the physical conveyor system; PLC data (status, sensor readings) feed the twin to simulate, troubleshoot, predict behavior under different conditions.