The rapidly evolving world of industrial automation, sensors play a critical role in bridging the gap between the physical and digital realms.

From a robotic arm detecting the exact position of an object to conveyor belt ensuring accurate material flow.

Furthermore, an autonomous vehicle avoiding collisions. All this because the sensors are at the heart of decision-making.

Among the many sensor technologies used for distance measurement and object detection, the ultrasonic sensors have proven to be a versatile and cost-effective solution.

This article explains how ultrasonic sensors work, explores their applications in automation industrial, and provides their advantages and disadvantages.

Furthermore, it compares ultrasonic sensors with other distance-sensing technologies.

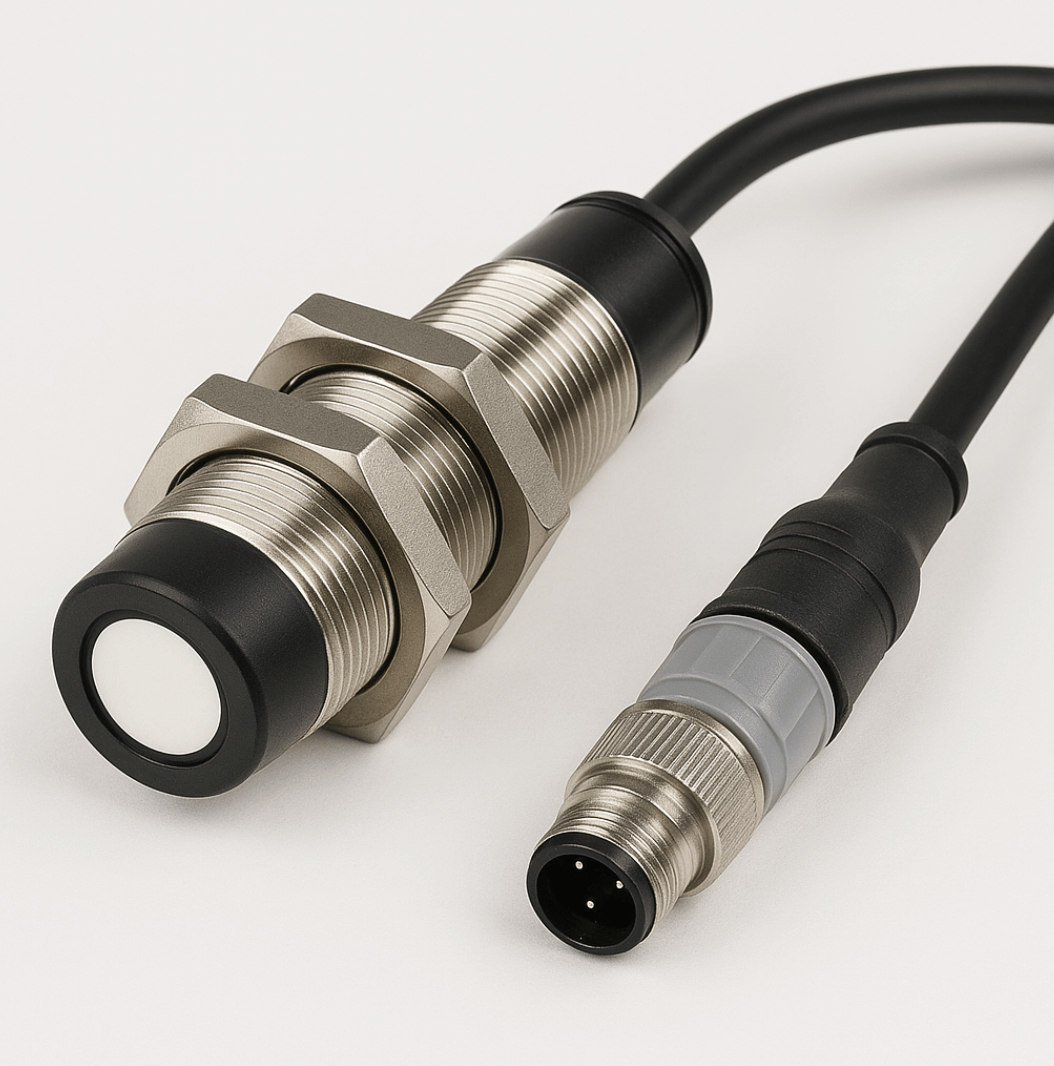

What Is an Ultrasonic Sensor?

An ultrasonic sensor is a device that measures the distance to an object by using sound waves.

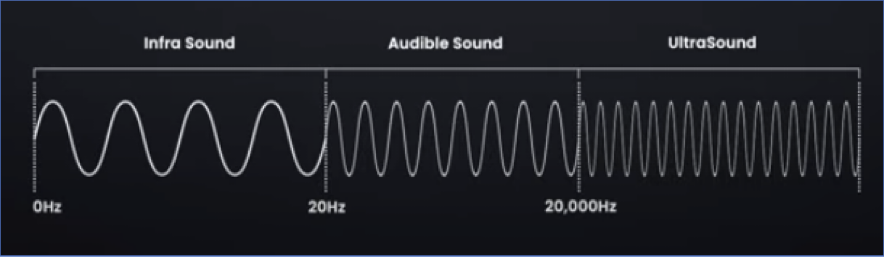

This task is done at frequencies higher than the audible range of humans, which is above 20 kHz, as it can seen in the figure below.

Infra – Ultrasound wave

Most of industrial ultrasonic sensors operate between 25 kHz and 70 kHz, though some specialized ones can go higher.

How does Ultrasonic Sensor Work?

The principle is based on echo-location, similar to how bats and dolphins navigate:

- The sensor emits a short ultrasonic pulse called trigger.

- The sound wave travels through the air until it hits an object.

- The wave reflects back to the sensor (echo).

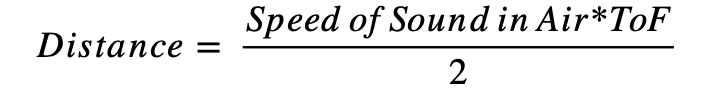

- The sensor calculates the time of flight (ToF) of the sound wave.

From the information of the above, the following basic formula is deduced:

The division by 2 accounts for the round trip (going to the object and returning).

Working Principle in Automation World

In an automation system, ultrasonic sensors typically consist of transducer, control circuit and the outputs:

- Transducer: Is in charge of converting an electrical signal into ultrasonic sound waves and vice versa.

- Control Circuit: Generates the pulse signal (trigger) and processes the received echo.

- Output Stage: Provides an analog or digital output for the automation controller such as PLC, microcontroller, or industrial PC.

Process Flow in Automation

From an automation point of view, the whole process of ultrasonic measurement works as explained below

- Triggering: The automation controller commands the sensor to emit a pulse.

- Propagation: The sound wave travels at approximately 343 m/s in air.

- Echo Detection: The sensor detects the reflected signal.

- Signal Processing: The time difference between sending and receiving is converted into distance.

- Decision Making: The automation system uses this distance data for tasks such as object positioning, counting, or safety control.

Applications of Ultrasonic Sensors in Automation

- Object Detection on Conveyor Belts: Detecting the presence or absence of packages and counting objects regardless of color or transparency.

- Liquid Level Measurement: Monitoring tank levels in process industries (chemicals, food, water treatment).

- Robotics and AGVs (Automated Guided Vehicles)

- Collision avoidance and obstacle detection.

- Packaging and Bottling Lines

- Checking the fill level of bottles (especially transparent materials where optical sensors struggle).

- Ensuring caps or lids are properly placed.

- Automotive Automation: Parking assistance and blind-spot monitoring.

- Industrial automotive robots using ultrasonic feedback.

- People and Object Counting: Entry/exit monitoring in automated systems.

- Smart building applications (lighting control, HVAC).

Advantages (Pros) of Ultrasonic Sensors

- Non-Contact Measurement & Simple Integration

- No physical contact needed, avoiding wear and contamination.

- Insensitive to Object Color and Transparency

- Works equally well on shiny, transparent, or dark surfaces, unlike optical sensors.

- Good Range Versatility: Can detect objects from a few centimeters to several meters away.

- Cost-Effective: Cheaper than laser rangefinders or 3D vision systems.

- Ruggedness: Can work in dusty, smoky, or poorly lit environments where cameras or IR sensors fail.

- Provides analog (voltage/current) or digital (switching) outputs directly compatible with PLCs.

Limitations (Cons) of Ultrasonic Sensors

- Environmental Sensitivity: Sound speed changes with temperature, humidity, and air pressure, affecting accuracy.

- Limited Resolution: Accuracy is typically within a few millimeters, not suitable for high-precision tasks.

- Slow Response Time: Since sound travels slower than light, measurement cycle times are longer compared to laser or IR sensors.

- Interference and Crosstalk: Multiple ultrasonic sensors operating close together can interfere with each other.

- Angle Dependence: Works best when objects are perpendicular to the sensor. Slanted or sound-absorbing surfaces reduce detection reliability.

Comparison with Other Distance Sensors

In this chapter we address the comparison of our sensor in stud against other sensors that use the same technology

Ultrasonic vs Infrared (IR) Sensors

IR sensors use reflected infrared light to detect distance, but Ultrasonic works regardless of color or transparency, not affected by ambient light. Unfortunately, Ultrasonic have slower response and lower resolution

Ultrasonic vs Laser Rangefinders (LIDAR)

Laser rangefinders measure distance using time of flight of light or phase shift, but Ultrasonic are cheaper, more rugged in dusty/dirty conditions. Although Ultrasonic have lower precision, shorter range, slower measurement.

Ultrasonic vs Vision Systems (Cameras + AI)

Vision systems provide rich data (shape, color, dimensions), while Ultrasonic are simple, inexpensive, and unaffected by lighting conditions.

On the other hand, Ultrasonic provides only distance information, no shape or color recognition.

Ultrasonic vs Capacitive/Inductive Proximity Sensors

Capacitive sensors detect changes in dielectric properties; inductive sensors detect metal objects.

On the other hand, Ultrasonic can detect any material (metal, plastic, glass, liquid). Although, Ultrasonic are larger size, slower response.

Future of Ultrasonic Sensors in Automation

With Industry 4.0 and IIoT (Industrial Internet of Things), ultrasonic sensors are evolving. Have started to include smart ultrasonic sensors with built-in temperature compensation to reduce environmental errors.

Network connectivity (EtherCAT, IO-Link, Modbus) for seamless integration in smart factories.

Process of miniaturization allowing their use in compact robotic systems. Also, hybrid sensing where ultrasonic sensors are combined with cameras or laser scanners for robust multi-sensor systems.

Conclusion

This article addressed about Ultrasonic sensors that use sound wave (echo-location) to obtain their measurement.

It also showed the applications of the later sensor together with the advantages and disadvantages.

Furthermore, the comparison with other types of sensors was demonstrated as well as future of Ultrasound was discussed.

After the above discussion, we can agree that Ultrasound sensors are one of the most versatile and cost-effective distance sensing solutions in industrial automation.

Their ability to detect objects regardless of color, transparency, or lighting conditions makes them indispensable in many applications, from conveyor belt monitoring to robotic navigation and liquid level measurement.

However, like any technology, they come with limitations: slower response, lower accuracy compared to optical systems, and environmental dependencies. The choice of sensor ultimately depends on the specific automation requirement.

In many cases, ultrasonic sensors serve as the perfect balance between cost, reliability, and performance, particularly when paired with other sensor technologies.

FAQ: How Does an Ultrasonic Sensor Work?

What is an ultrasonic sensor?

Ultrasound sensor is a device that is used to measure the distance. This sensor uses sound wave to detect how far the object is, just like bats and dolphins.

How does it operate?

It operates just like dolphin or bats, the send the wave and wait for it to reflect– back (echoing). Then they measure this delay time that is how they know how far is the object.

What’s the distance calculation formula?

Assume ToF is the that measure since the device send the wave until it echoed back, then

4. What components are involved?

It includes transducer, the component in charge of converting sound wave to electrical signal. A controller that processes the signal an send it to output.

What are the advantages?

Non-contact measurement, low coast, reliability, simple integration among others.