Programmable Logic Controllers (PLCs) are the heart of industrial automation. They control machines with precision, processes, and even entire plants, from small packaging machines to huge automotive lines. They ensure reliable operation.

Different PLC brands dominate different markets which varies regionally. Each brand has its own style, strengths, and weaknesses and different trade-offs.

For beginners, it can be confusing to understand why there are so many options.

In this article, we will discuss the most common PLC brands, their uniqueness and where are they used, examples are included. By the end, you will have a clear view of the global PLC landscape.

What is a PLC?

A PLC is a digital computer made for industrial use. It reads signals from inputs such as sensors and switches.

It processes these signals using a special program, and then controls outputs like lights, valves, or motors.

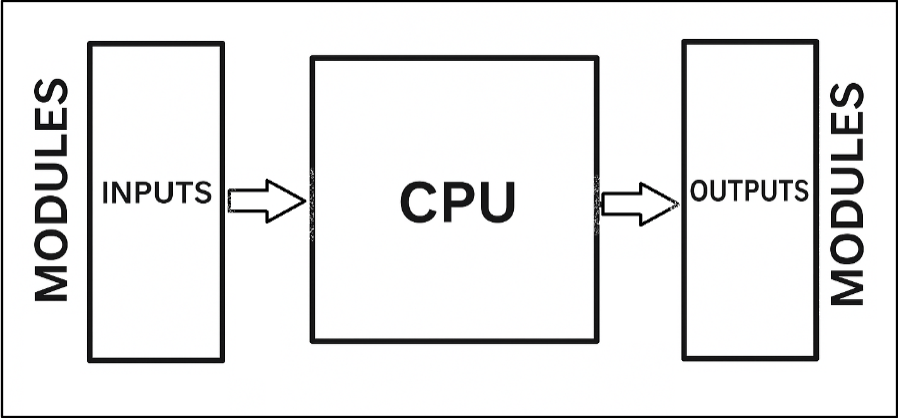

Schematically, the structure of a PLC looks like what is shown in the following diagram:

From the above structure shortly, the inputs bring information to the CPU. Furthermore, the CPU makes decisions after manipulating the information brought by the inputs.

Finally, outputs (actuators) take action. This basic structure is the same for all brands. What changes is the hardware, software, and philosophy of design.

Common PLC Brands

The well-known brands include: Siemens, Allen-Bradley (Rockwell Automation), Mitsubishi, Schneider Electric Omron and ABB.

Other known PLC brands are Delta Electronics, Honeywell, Keyence, Bosch Rexroth, and Toshiba. In this article we will discuss about the most famous ones.

Siemens

Siemens is one of the largest PLC brands worldwide. The most popular family today is the S7 series. Its main line is called SIMATIC.

Brief History

In the Year 1847, Siemens was established in Berlin under the name Telegraphen-Bauanstalt von Siemens & Halske, created by Werner von Siemens and Johann Georg Halske as a telegraph manufacturing company.

Over the years, it rapidly evolved into a worldwide leader in electrical engineering, branching out into power generation, transportation, and telecommunications.

By 1966, the modern Siemens AG came into existence through the merger of three Siemens firms, and today the company stands as a global technology giant with headquarters in Munich and Berlin.

Key Features

- Strong presence in Europe and Asia.

- Many models: S7-1200, S7-1500, and legacy S7-300/400.

- Powerful software IDE: TIA Portal for programming.

- Robust communication protocol.

- Integrated safety and motion control.

- Industry 4.0 support

Siemens PLCs are modular. You can add safety modules, analog modules and communication cards.

Their systems are robust and scalable. The software environment can feel complex for beginners. But once you learn it, you get access to very advanced functions.

Major Areas

Siemens is strong in

- Process industries.

- Factory automation for controlling production lines.

- Packaging machines

- Robotic systems.

- HVAC and security systems

- Chemical.

- Automotive.

Allen-Bradley (Rockwell Automation)

Allen-Bradley is the leader in North America. It is owned by Rockwell Automation. Their PLCs are famous in the U.S. and often found in large plants.

Brief History

Allen-Bradley was originally founded in 1903 as the Compression Rheostat Company by Dr. Stanton Allen and Lynde Bradley.

In 1910, it officially became the Allen-Bradley Company after creating controllers and resistors designed for both industrial and commercial applications.

These products gained major importance during the radio expansion of the 1920s and later in WWII, where demand surged.

Its continuous innovation in industrial automation, particularly in the advancement of PLCs, eventually led to its acquisition by Rockwell Automation in 1985, where today Allen-Bradley remains a core brand within the company.

Key Features

- Main families: MicroLogix, CompactLogix, ControlLogix.

- Uses RSLogix 5000 and Studio 5000 software.

- Strong integration with HMIs and drives.

- Programming flexibility.

- Redundancy.

- Built-in diagnostics and safety.

Allen-Bradley products are designed with user-friendly hardware. They have easy wiring, clear labeling, and rugged design. They are also known for high prices compared to other brands.

Major Areas

- Oil and gas.

- Automotive.

- food production.

- Manufacturing process.

- Transportation systems.

- Material handling.

- Building automation.

- Water and wate-water.

In the U.S. Allen-Bradley is often the default choice.

Mitsubishi Electric

Mitsubishi is a well-known brand in Asia. It offers reliable and cost-effective PLCs. The two most popular lines are FX series and Q series.

Brief History

Mitsubishi traces its origins back to 1870, when YataroIwasaki founded it as a shipping business.

Over time, it grew into a large, diversified industrial group known in Japan as a zaibatsu.

After WWII, the Allied occupation ordered the dissolution of the zaibatsu, which resulted in the creation of independent companies.

Today, firms such as MitsubishiCorporation, MitsubishiHeavyIndustries, and Mitsubishi Electric still carry the iconic three–diamondlogo and share a common legacy, though they operate separately without a central governing body.

Key Features

- Compact PLCs with strong motion control support.

- Programming software: GX Works.

- Good integration with Mitsubishi robots and drives.

- Wide product range.

- High-speed processing.

- Strong networking.

Their FX series is widely used in packaging and small machines and Q series is modular and used in larger systems.

Mitsubishi stands out for motion and robotics. Factories that use Mitsubishi robots often also use Mitsubishi PLCs.

Major Areas

- Process industries

- Utilities

- Building automation.

- Automotive industry.

- Electronics and semiconductors.

- Industrial automation.

- Manufacturing.

Schneider Electric

Schneider Electric produces the Modicon line of PLCs. This is historically important, since Modicon invented the first PLC in 1969.

Brief History

The story of Schneider Electric dates back to 1836, when the Schneiderbrothers established Schneider& Cie, an iron and steel enterprise in France.

During the late 19th and early 20th centuries, the company expanded into a major player in heavy industry.

After WWII, it redirected its strategy toward the fast-growing electrical equipment and automation sectors.

By the 1960s, Schneider had positioned itself as a specialist in electrical equipment. A pivotal step came in 1981 with the acquisition of Modicon, the inventor of the PLC.

The 2000 merger with Square D further extended its reach into North America. In 2007, Schneider strengthened its role inpower distribution and data centers by acquiring APC (American Power Conversion).

Key Features

- Famous series: M221, M241, and M580.

- Uses EcoStruxure Machine Expert software.

- Good energy management integration.

- Robustness.

- Flexible programming.

- Built-in cybersecurity.

Their PLCs are strong in power monitoring and smart grid applications.

Major Areas

- Water treatment and electrical distribution.

- Power and Energy

- Manufacturing and machinery

- Process industries

- Building automation

Omron

Omron is a Japanese brand with a global footprint. It is known for its mid-size PLCs and sensors. The CJ series and NX series are common choices.

Brief History

Omron was founded in 1933 in Osaka, Japan, by KazumaTateishi as Tateishi Electric Works, initially producing timer switches for X-ray photography.

In 1945, the company relocated to Kyoto, and by 1948 it was incorporated as Tateishi Electric Corporation.

The Omron brand was launched in 1959, signaling a new wave of innovation.

Notable achievements included introducing the world’s first contactless proximity switch in 1960 and developing the first online cash machinein1971.

Later, the company officially adopted the name Omron Corporation, derived from its founding district in Kyoto, to highlight both its globalexpansion and its mission of advancing society through technology.

Key Features

- Easy integration with Omron sensors.

- Good networking options: EtherCAT, Ethernet/IP.

- Programming software: CX-Programmer and Sysmac Studio.

- High-speed processing.

- Durability and scalability

- Safety and security

.

Their PLCs are often paired with vision systems for quality inspection.

Major Areas

- Automation of packaging, food, and logistics.

- Electrical components.

- Equipment and systems.

- Medical devices.

ABB

ABB is a Swiss-Swedish company. It is better known for drives, motors, and robotics. But ABB also makes solid PLCs.

Brief History

ABB was created in 1988 through the merger of ASEA from Sweden and Brown, Boveri & Cie from Switzerland, both established in the late 19th century and recognized as pioneers in electrical engineering.

Since then, ABB has grown into a global leader in electrification and automation. Among its major achievements are the invention of the 3-phase power system.

Also, the introduction of the world’s first commercial high-voltage shore-to-ship power connection.

With deep roots in innovation from its predecessor companies, ABB has continued to shape progress in power generation, robotics, and digital technologies.

Key Features

- Popular series: AC500.

- Strong in process automation and utilities.

- Supports many communication protocols (PROFINET, Modbus, CANopen).

- Safety and integration.

- Motion control capabilities.

- Modular and scalable design.

The AC500 series is modular and scalable. It fits well into large energy and infrastructure projects.

Major Areas

- Infrastructure and transportation.

- Marine and offshore.

- Process industries.

- Power and utilities.

- Water and wastewater.

Delta Electronics

Delta is a Taiwanese company. It is known for affordable automation products. Its PLCs are growing in popularity in Asia and developing markets.

Brief History

Delta Electronics was established in Taiwan in 1971 by Bruce Cheng, beginning with the production of TV deflection coils and electronic components.

The company quickly expanded by focusing on high-efficiency switching power supplies, which helped it rise as a worldwide leader in power electronics.

Over the years, it extended its global footprint with numerous R&D centers and manufacturing facilities across different regions.

Today, Delta is recognized as a leading provider of power and thermal managementsolutions, emphasizing energy efficiency and sustainability.

Its product portfolio now spans industrial automation, networking, display technologies, and other advanced applications.

Key Features

- Main family: DVP series.

- Simple, compact, and low-cost.

- Easy connection with Delta HMIs and drives.

- Wide I/O options.

- Advanced motion control.

- Energy efficiency.

Delta is popular for small to medium machines. Many OEMs use them for cost-sensitive projects.

Major Areas

- Textile and printing.

- HVAC and building control.

- Electronics assembly.

- Material handling.

- Packaging machine.

Keyence

Keyence is famous for sensors and vision systems. But they also provide compact PLCs. Their main line is the KV series.

Brief History

Keyence was founded in 1974 by Takemitsu Takizaki in Osaka, Japan, beginning with the development of photoelectric sensors for manufacturing applications.

By 1982, the company had broadened its product range to include barcode readers and laser markers.

It entered the North American market in 1990 and was later listed on the Tokyo Stock Exchange in 1997.

Today, Keyence stands as a global leader in industrial automation, recognized for its cutting-edge sensors, machine vision systems, microscopes, and precision measuring instruments, all distributed through its worldwide direct sales network.

Key Features

- Series: KV-X and KV-8000

- Strong integration with vision inspection.

- Very compact designs.

- Fast scan times for small automation tasks.

- Ultra-high-speed motion control.

- High-performance CPU.

Major Areas

- Packaging labeling.

- High-speed inspection systems.

- Electronics manufacturing.

- Automated testing stations.

- Sorting and logistics.

Panasonic

Panasonic also produces PLCs, though less common globally. They are mainly used in Asia.

Brief History

Panasonic began in 1918 as Matsushita Electric Housewares Manufacturing Works, founded by Kōnosuke Matsushita to make lamp sockets and plugs.

Over time, the company expanded into a broad portfolio of consumer and industrial electronics, including irons, radios, televisions, and stereo systems.

It was incorporated in 1935 and introduced the “Panasonic” brand for its audio products in 1955.

Later, in 2008, the company officially changed its name to Panasonic Corporation, and in 2022, it transitioned to Panasonic Holdings Corporation under a new holding company framework.

Key Features

- FP series is their main line.

- Compact and suited for small machines.

- Good cost-performance ratio.

- High-speed motion control.

- Robust IEC 61131-3 software.

- Compactness and scalability.

Panasonic PLCs integrate well with their sensors and servo drives.

Major Areas

- Assembly automation.

- Electronics manufacturing.

- Packaging equipment.

- Building automation.

- Textile and printing.

Which PLC Brand to Use

Choosing a brand depends on several factors:

- Region

Availability and support vary by country.

In the U.S., Allen-Bradley dominates.

In Europe, Siemens is common.

In Asia, Mitsubishi and Omron are strong. - Industry

Automotive plants often use Siemens or Allen-Bradley.

Packaging companies may prefer Omron or Mitsubishi.

Energy utilities may use ABB or Schneider. - Integration

If a plant already uses a brand of drives or robots, the same brand of PLC may be easier to integrate. - Budget

Delta and Panasonic are more cost-effective.

Siemens and Allen-Bradley are premium but powerful.

The Future of PLC Brands

The PLC world is evolving. Trends like IIoT, cloud integration, and edge computing are shaping the future.

Major brands now focus on connectivity and data analysis.

- Siemens promotes digital twins and Industry 4.0.

- Allen-Bradley pushes connected enterprise solutions.

- Omron and Keyence focus on vision and AI integration.

Despite changes, the core role of PLCs remains. They must be reliable, rugged, and real-time.

Conclusion

This article explored the leading PLC brands, highlighting what makes each unique and where they are most commonly used.

By the end, we gained a clear picture of the global PLC market, recognizing that PLCs come in a wide variety of brands and models.

Siemens is the dominant player in Europe, Allen-Bradley holds strong in North America, while Mitsubishi, Omron, and others stand out in Asia.

Brands like Delta, Panasonic, ABB, Schneider, and Keyence also play significant roles worldwide.

When it comes to selecting a PLC, every brand offers distinct advantages. The ideal choice often depends on the region, industry requirements, and system integration needs.

At their core, however, all PLCs perform the same essential function: they take inputs, process logic, and control outputs.

The underlying principle is universal understanding the differences simply help engineers make better, more informed decisions.

FAQ: Common PLC Brands Explained

Which PLC brand is the most widely used?

According to market share, Siemens’ SIMATIC PLCs are the most commonly used, followed by Rockwell.

How do I choose the right PLC brand for my application?

You should consider factors like regional support, industry requirements, software compatibility, and scalability.

Are there significant differences in programming software among PLC brands?

Yes, each brand offers unique programming environments. Siemens uses STEP7, Rockwell Automation offers Studio 5000, and Omron provides Sysmac Studio

Can PLCs from different brands communicate with each other?

Yes, many modern PLCs support standard communication protocols like Modbus, Ethernet/IP, and Profinet, allowing for interoperability between different brands.