Programmable Logic Controllers (PLCs), are everywhere in the industrial automation.

They control industrial processes, machines, production lines, and entire plants. They have done so for decades.

Historically, PLCs were standalone devices. They operated on-site, so their data stayed locally but, industries want data everywhere.

The rise of cloud computing changed this. Now, cloud-connected PLCs are transforming manufacturing.

They are a core part of Industry 4.0. This new generation of PLCs connects industrial systems to the cloud.

This connectivity unlocks many new possibilities. This shift represents a major change because it moves operations beyond traditional factory walls.

This article explores what cloud-connected PLCs are, how they work, and why they matter. We will also look at benefits, challenges, use cases, and the future of this technology.

PLC in Short

A PLC is an industrial computer that controls machines and processes. It reads inputs, processes logic, and activates outputs.

Inputs can be sensors, switches, or transmitters. Outputs can be motors, valves, or relays.

The PLC follows a program. Most programs use ladder logic or function block diagrams.

PLCs are reliable, robust, and designed for harsh environments. That is why they are used in factories, oil rigs, water plants, and energy systems.

Traditional to Cloud-Connected PLC

Traditional PLCs were powerful but they had a larger number of limitations. They lacked deep analytics and their data was trapped locally, which means remote access was difficult.

Sharing data with enterprise systems was a chore, this created a divide. Operational Technology (OT) and Information Technology (IT) were separate, fortunately, cloud-connected PLCs bridge this gap.

They act as edge devices by processing some data locally. Next, they send relevant data to the cloud. This streamlines the flow of information

What is the Cloud?

The cloud is not a single place, instead it is a network of servers. These servers store data, run applications, and provide services.

Cloud computing allows remote storage and analysis. It provides scalability, flexibility, and accessibility.

Companies use cloud platforms like AWS, Azure, and Google Cloud. Industrial platforms also exist, such as Siemens MindSphere and PTC ThingWorx. The cloud is everywhere that is why it is transforming automation.

Cloud-Connected PLCs Explained

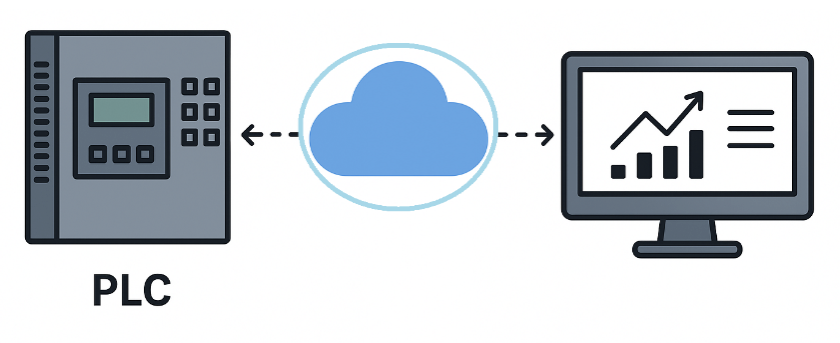

A cloud-connected PLC is a PLC that communicates with the cloud. It collects machine data and sends it to cloud servers.

This connection can be direct because some PLCs have built-in cloud support. They can send data natively using protocols like MQQT and OPC-UA, while others connect through gateways.

The cloud then processes the data. It can then store, analyze, or visualize it, or even send commands back to the PLC.

This situation creates a two-way link as shown in the diagram below. The machine is no longer isolated, it is part of a global system instead.

Why Connect PLCs to the Cloud?

Industries need more than control, and they also need insights. They want predictive maintenance, energy optimization, and global monitoring.

Cloud-connected PLCs make this possible since they allow decision-makers to see real-time data.

For example, a plant manager in Tanzania can monitor machines in Mexico. A service engineer can detect faults before they happen. So, this can prove that cloud-connected PLCs create smarter factories.

Key Features of Cloud-Connected PLCs

- Visualization: Dashboards show trends, graphs, and alerts.

- Analytics: Cloud software runs AI and machine learning models.

- Data Logging: Machine data is stored in the cloud.

- Integration: Cloud platforms connect with ERP, MES, and SCADA systems.

- Remote Access: Engineers can log into the PLC from anywhere.

Benefits of Cloud-Connected PLCs

Remote Monitoring

Operators do not need to be on-site. They can monitor machines from a laptop or smartphone. This saves time and reduces travel.

Predictive Maintenance

Machine data predicts failures. The cloud runs algorithms to detect early signs of wear. This reduces downtime.

Scalability

One PLC or one thousand. The cloud can handle it. Companies can expand operations without major changes.

Lower Costs

Cloud platforms reduce the need for local servers. Maintenance costs are lower.

Better Collaboration

Different teams can access the same data. Engineers, managers, and executives work together more effectively.

Challenges of Cloud-Connected PLCs

Cybersecurity

Connecting PLCs to the cloud increases risks. Hackers may target machines. Strong encryption and firewalls are critical.

Connectivity

Factories in remote areas may lack reliable internet. Without stable connections, cloud integration suffers.

Latency

Cloud data transfer takes time. For time-critical processes, this can be an issue.

Cost of Transition

Upgrading old PLCs to support cloud can be expensive. Some need gateways or replacements.

Training

Operators and engineers must learn new skills. Cloud systems require IT and OT collaboration.

Use Cases of Cloud-Connected PLCs

Manufacturing

Factories can track production in real time. Machine performance and energy use are visible in dashboards.

Energy

Power plants use cloud-connected PLCs for monitoring turbines and generators. Renewable energy farms use them for wind and solar optimization.

Water Treatment

Water plants monitor pumps, valves, and chemical dosing. Remote access allows central control.

Oil and Gas

Pipelines and drilling sites often span large areas. Cloud-connected PLCs provide visibility from a central hub.

Building Automation

HVAC, lighting, and security systems can be controlled remotely. Data helps reduce energy costs.

How Do PLCs Connect to the Cloud?

There are different methods.

Direct Connection

Some PLCs have cloud-ready firmware. They send data directly to platforms like AWS IoT.

IoT Gateways

A gateway collects PLC data and forwards it. This is common with older PLCs.

Edge Devices

Edge devices preprocess data before sending it to the cloud. This reduces bandwidth use.

SCADA Integration

Existing SCADA systems can bridge the gap between PLCs and cloud servers.

Security in Cloud-Connected PLCs

Security is a major concern cloud-connected technology. To achieve it, the following best practices must be attained:

- Encryption: Protects data in transit.

- Authentication: Only authorized users can access systems.

- Firewalls: Block unauthorized traffic.

- Network Segmentation: Isolates critical systems.

- Regular Updates: Keeps firmware safe from vulnerabilities.

Companies must balance connectivity with safety.

The Future of Cloud-Connected PLCs

Cloud adoption in industry is still growing. In the future, cloud-connected PLCs will be standard. We expect to see:

- More AI Integration: Cloud AI will optimize entire factories.

- Digital Twins: Virtual models of machines will simulate performance.

- 5G Networks: High-speed connections will reduce latency.

- Edge-Cloud Hybrids: Edge devices will handle local control. The cloud will handle big data analysis.

Conclusion

This article addressed cloud-connected PLCs. It detailed what are they, how they work, and why they matter.

It also showed the benefits, challenges, use cases, and the future of this technology.

So from the above we can say that the PLCs transformed industry decades ago, and the cloud is transforming them again today.

Cloud-connected PLCs bring visibility, efficiency, and intelligence. They reduce downtime, improve collaboration, and cut costs.

Challenges exist, but the benefits are clear. Cybersecurity, training, and connectivity must be addressed.

The future of automation is connected, and cloud-connected PLCs are not just a trend. They are the foundation of Industry 4.0.

Factories are no longer isolated. Machines are no longer silent. Data flows freely, and decisions are smarter. We are already in the age of cloud-connected PLCs.

FAQ: Cloud-Connected PLCs

How does cloud-connected plc work

By transmitting operational and control data from a manufacturing or industrial automation environment to a cloud platform for real-time monitoring, data analysis, and remote management.

Do cloud-connected PLCs replace SCADA?

No. SCADA systems still play a key role. Cloud platforms extend SCADA with global access.

Are cloud-connected PLCs safe?

Yes, if proper cybersecurity measures are in place.

Can old PLCs connect to the cloud?

Yes, through gateways or edge devices.

Do cloud-connected PLCs need constant internet?

Not always. Some store data locally and sync when internet returns.

What industries benefit most?

Manufacturing, energy, oil and gas, and utilities see the biggest benefits.