Programmable Logic Controllers (PLCs) are the heart of modern industrial automation.

They monitor inputs, and through outputs, they bring systems to life. But what happens when you download your program, set everything up, run the PLC and nothing comes output not working?

This problem is one of the most common headaches for engineers, technicians, and even students learning PLCs.

It is headache cause could be almost anywhere, in the program, in the hardware, in the wiring, or even in the external power supply.

So, this article explores the different reasons a PLC output may not respond, how to approach troubleshooting without, and how to prevent these issues from happening again.

Understanding PLC Outputs

To understand why an output isn’t working, we first need to understand what a PLC output actually is.

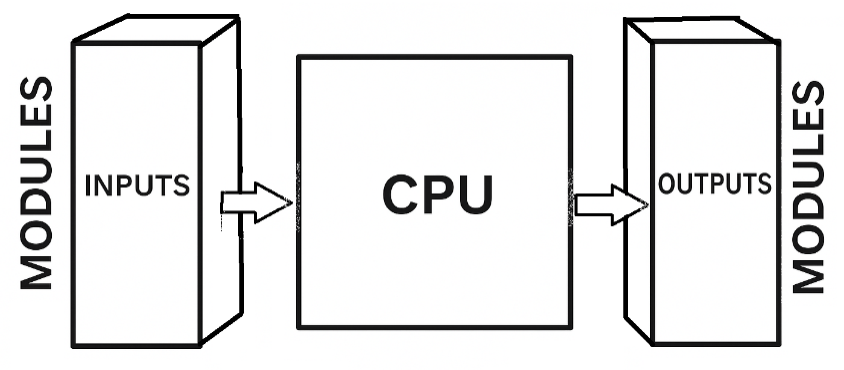

An output is the way a PLC communicates with the outside world. If the input side is like our human senses, the outputs are the hands and voice that make things happen.

Depending on the application, outputs can be switching a relay, turning a motor on, or energizing a solenoid.

Types of PLC Outputs

Different PLCs have different output modules, and this matters when troubleshooting.

Relay Outputs

Think of them as little switches inside the PLC. They’re versatile because they can handle both AC and DC loads, but they’re relatively slow.

Transistor Outputs

These are fast and reliable for DC applications, commonly used when precision is needed

TRIAC Outputs

These are designed for AC loads such as lamps, heaters, and solenoids. They’re slower than transistors but ideal for AC switching.

Each type has strengths and weaknesses. Knowing which one you’re using is essential. A common mistake is connecting the wrong type of load to the wrong output module.

How PLC Output Problems Show Up

A PLC output that isn’t working doesn’t always fail in the same way. Sometimes it’s obvious, other times it’s subtle. Here are common symptoms:

- The PLC software shows the output is ON, but the field device doesn’t respond.

- The output never turns ON, even though the program conditions seem right.

- The output works but behaves erratically, flickering or dropping out.

- The output seems frozen, stuck either ON or OFF.

Each symptom is like a clue that points you closer to the real cause.

Why Isn’t My PLC Output Working?

Now let’s look at the most common culprits, explained in plain language.

The Program Isn’t Doing What You Think

The number one cause isn’t hardware — it’s the logic itself. Maybe the conditions in your rung don’t actually turn on the output, or maybe another part of the program is switching it off again.

In some cases, the program may require the machine to be in “Auto” mode, but you’re testing it in “Manual.”

What to do

Go online with the PLC and watch the logic in real time. If the output coil isn’t energizing in the software, the issue is with your code, not the hardware.

The Output Has Been Forced

Most PLC software allows inputs and outputs to be forced ON or OFF for testing. If someone forced an output OFF before and forgot to clear it, no amount of correct logic will bring it back.

What to do

Always check if any outputs are forced. Clear them before running the program.

Power Supply Problems

Outputs usually require an external power supply for example, a 24 VDC transistor output needs that 24 VDC source to energize the load. If that supply is missing, disconnected, or incorrectly wired, the output won’t work.

What to do

Measure the voltage at the PLC’s output terminal with a multimeter. If no voltage is present, trace the wiring back to the power supply.

Protection Devices Have Tripped

Many PLC output modules are protected by fuses or circuit breakers. If a short circuit or overcurrent occurred, the fuse may have blown, silently cutting off the output.

What to do

Inspect the module for fuses or check the control panel for tripped breakers. Replace or reset as needed, but also investigate why the fuse blew in the first place.

Wiring Mistakes

Incorrect wiring is one of the simplest yet most common reasons for output problems. Maybe the common terminal wasn’t connected, maybe the polarity is reversed, or maybe a wire has come loose.

What to do

Trace the wiring carefully. Confirm with a continuity tester that the path from PLC to device is intact. Don’t overlook simple things like loose screws or corroded terminals.

The Load Device Itself Has Failed

Sometimes the PLC is working perfectly, but the motor, valve, or lamp is faulty. For example, a solenoid coil could be burned out, or a lamp filament could be broken.

What to do

Test the device independently by applying power directly to it. If it doesn’t respond, replace it.

The Output Module Has Failed

Just like any other electronic device, PLC modules can fail. Surges, overheating, or overloading can damage them.

Symptoms include outputs that never energize, outputs that are stuck ON, or modules that smell burnt.

What to do

If your PLC has spare channels, try moving the output to another one. If that works, the module channel is bad. If not, you may need to replace the entire module.

Wrong Output Type for the Load

It is a classic mistake: connecting an AC load to a DC output or vice versa. A transistor output will never drive an AC lamp, no matter how perfect your wiring is.

What to do

Double-check that the load matches the output type (relay, transistor, or TRIAC).

Electrical Noise or Interference

In noisy industrial environments, electromagnetic interference (EMI) can cause strange behavior. Outputs may chatter, flicker, or respond inconsistently.

What to do

Improve grounding, use shielded cables, and add suppression devices like RC snubbers or diodes.

PLC CPU or System Faults

Finally, though rare, the PLC’s brain itself may have issues. A hardware fault in the CPU or a major error in the system could stop outputs from updating.

What to do

Check diagnostic LEDs, review error codes, and, if necessary, perform a restart.

A Logical Approach to Troubleshooting

When you face a dead output, the worst thing you can do is panic and start changing everything at once. A structured approach saves time and prevents mistakes.

- Start with the program: Is the coil actually ON in the software?

- Check for forces: Make sure the output isn’t locked out.

- Look at indicators: Most PLC output modules have LEDs that show if they’re active.

- Measure with a meter: Is voltage present at the terminal?

- Trace the wiring: Is the connection to the load solid?

- Test the load: Does it work with an independent power source?

- Inspect protection devices: Any blown fuses or tripped breakers?

- Try another channel or module: To rule out hardware failure.

- Review system diagnostics: Are there CPU or module error codes?

This step-by-step process narrows down the possibilities quickly and logically.

Preventing Output Problems Before They Happen

Troubleshooting is necessary, but prevention is better. Here are best practices to avoid output issues in the first place:

- Choose the right module for your load — don’t overload channels or use the wrong type.

- Wire correctly and neatly, following manufacturer diagrams.

- Use protective devices such as fuses, breakers, and surge suppressors.

- Maintain equipment regularly, tightening terminals and checking loads.

- Write clean, documented code so logic errors are less likely.

- Test devices periodically so you catch failing components before they cause downtime.

Key takeaways: Why Is My PLC Output Not Working?

In this article, we addressed the causes, troubleshooting steps, and preventive measures to solve output-related issues in PLCs. Because a non-working PLC output is not a mystery.

With a clear understanding of PLC hardware and a structured troubleshooting approach, you can bring systems back online quickly and prevent downtime in the future. When a PLC output is not working, it can bring entire systems to a halt.

Fortunately, most problems can be traced to logical errors, wiring issues, power supply faults, or failed field devices.

By systematically checking program logic, module indicators, wiring, power, and load, you can pinpoint the issue efficiently.

FAQ: Why Is My PLC Output Not Working?

The output LED is ON but the device doesn’t move—what next?

Revise a blown fuse, broken wire, or bad device

There’s no voltage at the output—could it be a missing supply/common?

Check if there is power the power block, if yes then could be different reasons. One of them may be the output was forced OFF. In this case run your PLC in online mode

Could safety circuits or interlocks be blocking outputs?

Yes, in this case check what causes them to be triggered

Do wiring mistakes cause “no output”?

Absolutely yes, it might be causing for safety circuit to be triggered

Could environmental or power issues be affecting outputs?

Yes, especially if you are located in area with high amount of electromagnetic interference (EMI).