A motor starter is a simple device that controls an electric motor. It is used to safely turn the motor on and off and protect it during operation.

A contactor and an overload relay are combined within a single unit to form a motor starter.

While the overload relay acts as a safety mechanism, the contactor is the one that connects power to the motor. Starters are essential components in a large number of industrial applications. These include conveyors, fans, and manufacturing equipment, among others.

They are designed to provide reliability and safety. Faults from overcurrent, power surges, or mechanical faults can be mitigated by the use of starters.

For electrical engineers and technicians, it is crucial to understand how a motor starter works.

This article reviews what motor starters are, how they work, and their types and applications.

Basic Components of a Motor Starter

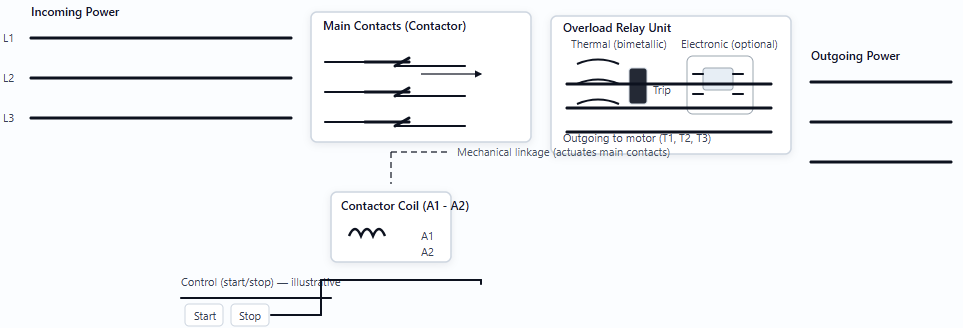

A motor starter is really just a team of a few key parts working together in perfect sync. It is composed mainly of two core components: a contactor and a safety feature called an overload protective relay.

Sometimes it may contain an extra part, such as a built-in fuse and a circuit breaker. This configuration is referred to as a combination starter. The contactor is basically a tough, heavy-duty electrical switch designed for robust, frequent switching of high currents.

It uses a little magnetic coil to work. When you send power to that coil, it acts like a magnet, pulling the main switch contacts closed and letting electricity zoom to the motor.

If you cut the power to the coil, a spring instantly pops those contacts open, effectively stopping the motor. The overload relay plays a crucial role as your motor’s personal safety guard.

Its single job is to constantly watch how much power the motor is pulling in. The relay “trips” if the motor unexpectedly tries to draw too much power for an extended period (perhaps due to a jam). That action cuts the control power, instantly telling the main contactor to shut down everything and safely stop the motor.

How a Motor Starter Works

The operation of a motor starter is a sequence of electrical actions. A user pushes a “Start” button to send a low-voltage signal to the starter’s control circuit.

This control power then energizes the contactor coil. The magnetic force pulls the main power contacts closed instantly.

High-voltage power then flows from the main supply lines through the closed contacts. Furthermore, it passes all the way to the overload relay’s current sensors and finally out to the motor windings. The motor begins to run.

To stop the motor, the user pushes a “Stop” button. This action interrupts the control circuit power.

The contactor coil becomes de-energized, causing the main power contacts to spring open. This stops the flow of electricity to the motor, which causes it to coast to a stop.

When a fault occurs, such as the motor jamming or a bearing seizing, the motor draws excessive current.

The overload relay detects this high current. After a short delay (designed to allow for normal starting surges), the overload trips.

It opens a set of auxiliary contacts in the control circuit, forcing the contactor to drop out and cutting power to the motor.

Motor Inrush Current

Electric motors require a large surge of current when they first start up. This is called inrush current or locked-rotor current. It can be several times higher than the motor’s normal running current.

A motor starter is designed to handle this massive initial current safely. A basic starter applies the full line voltage immediately. This procedure provides high starting torque but generates a large current spike.

The overload relay has a built-in time delay mechanism. This delay allows the motor to accelerate to speed without nuisance tripping from the normal inrush current. Once running, the current drops to the normal full-load amperage (FLA).

Types of Motor Starters

Not all applications require full voltage starting. Different kinds of motor starters are available to suit specific needs.

Direct Online (DOL) Starters

This is the most common type. It applies full line voltage to the motor terminals immediately.

They are simple, reliable, and cheap. They are best for small to medium motors where the sudden start is acceptable.

Reduced Voltage Starters

These are used for large motors. They limit the starting current surge and reduce mechanical stress on the machinery.

Common types include wye-delta (star-delta) starters, primary resistor starters, and autotransformer starters.

These methods apply a lower voltage initially, gradually increasing it until the motor reaches full speed.

Soft Starters

These are electronic reduced-voltage starters. They use solid-state components such as IGBTs and SCRs to smoothly ramp up the voltage.

This results in a very smooth start and stop sequence. They offer highly precise control over acceleration and deceleration times.

Variable Frequency Drives (VFDs)

VFDs are the most advanced option when it comes to a motor’s start control. They don’t just start and stop the motor.

They control the motor’s speed throughout its operation by changing both the voltage and the frequency of the power supplied. VFDs also include built-in motor protection.

Applications of Motor Starters

Motor starters are ubiquitous in industrial settings. They are used wherever an electric motor needs-controlled operation.

- Pumps and Fans: Starters ensure smooth operation and protection in HVAC and water systems.

- Conveyor systems use starters for reliable start/stop cycles.

- Machine tools and mixers rely on them for power and safety.

Starters are found in every manufacturing process, managing motors that drive production. The appropriate type of starter is selected based on the motor-size, load type, and the required starting smoothness.

Combination Starters

A combination starter integrates the components needed to start the motor with a dedicated disconnect mechanism, all housed within a single enclosure. This disconnect can be a switch, a fuse block, a circuit breaker, or another type of switch.

This design offers enhanced safety and convenience. It ensures that all power to the starter can be completely locked out for maintenance or repair work. This layout meets many industrial safety regulations.

Conclusion

This article explores what motor starters are, how they work, and their types and applications.

A motor starter is far more than just an on/off switch. It is a vital control and safety device for electric motors.

By combining contactors for power control and overload relays for protection, it ensures reliable and safe industrial operations.

Whether a simple Direct Online starter or a sophisticated Variable Frequency Drive, the right motor starter is essential for the longevity of the motor and the safety of the operating personnel.

FAQ: What is a Motor Starter?

What is a motor starter?

A motor starter is a device that switches a motor on or off and safeguards it against overloading.

Why is a motor starter needed?

Motors draw very high current at startup; the starter limits damage and provides protection.

What are the main parts?

The main parts are a contactor, which switches ON/OFF, and an overload relay, which protects against excess current.

How does it work?

The start signal energizes the contactor coil, which closes the contacts and allows the motor to run.

If an overload occurs, the relay will trip, opening the contactor and stopping the motor.

Does every motor need a starter?

Small motors sometimes don’t, but protection is still recommended.

What types of starters exist?

There are several types of starters available, including manual starters, DOL, star-delta, soft starters, and VFDs.

What protection does it provide?

Overload, phase loss/single phasing protection, and (with fuses/breakers) short-circuit protection.

Is a starter the same as a motor controller?

No. A controller manages logic; a starter provides switching and protection.