In industrial automation systems, there is a fundamental concept known as time-based control.

Many industrial processes rely on precise timing. This helps to ensure correct, consistent performance, safe operation, and sequencing.

Motors often require delayed starts to limit inrush current, valves must open and close in a defined order, and safety systems frequently depend on timing logic to avoid false trips or equipment damage.

Timers provide the mechanism to implement these time-dependent actions in control systems.

They are widely used in motor control circuits, relay-based panels, and programmable logic controllers (PLCs). Also, they are found in embedded automation devices.

This article presents a comprehensive explanation of the main types of timers used in industrial automation, describing their operating principles, typical applications, and practical considerations

Need for Timers in Industrial Automation

In industrial automation, a timer is one of the control elements. It works by changing its output state after a specified period of time.

Unlike sensors, timers do not measure physical quantities such as flow, pressure, or temperature.

Instead, they operate based on elapsed time, which begins when a defined input condition becomes true.

This input is usually a digital signal, such as a contact closure, a PLC logic bit, or the output of another control function.

Actions within a process can be well coordinated by engineers with the help of timers.

They must ensure that not only do events occur at the correct moment, but also in the correct order. Without timers, the stability and safety of many automation systems would be degraded.

For instance, starting multiple motors simultaneously could overload the electrical supply. Likewise, overheating may occur when stopping cooling fans immediately after a machine shuts down.

By introducing controlled delays and time windows, timers improve reliability and protect equipment. They also enhance overall process efficiency.

Classification by Operating Mechanism

In modern industrial settings, timers are broadly categorized into two physical forms: hardware-based relays and software-based instructions.

Mechanical and Electromechanical Timers

Physical components are utilized in these types of timers. These physical components could be like motors, gears, and even springs. While increasingly rare in new high-tech installations, they are still used today.

Their extreme durability makes them gain value. In high-vibration or high-heat environments, electronics might fail. This is where the value of mechanical and electrotechnical timers comes in.

Electronic and Digital Timers

Utilizing microcontrollers and quartz crystal oscillators, these provide much higher precision (often ±0.1% accuracy).

They typically feature digital displays for easy configuration. Also, it can handle multiple complex timing modes in a single unit.

Classification by Functions

The “type” of timer is most often defined by how its output reacts to an input signal. There are four dominant logic functions used currently in industrial automation:

On-Delay Timer (TON)

The On-Delay timer is the most frequently used instruction in PLC programming.

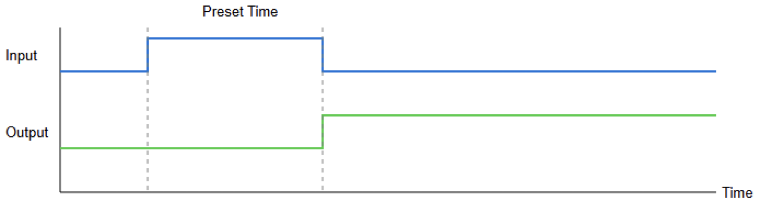

Operation

When the input signal (trigger) is activated (ON), the timer begins counting. During this time, the output remains OFF. Then, if the preset time has elapsed, the output turns ON. Sequential motor starting.

To prevent massive current surges, a series of TON timers can be used to start multiple motors one by one rather than all at once.

Off-Delay Timer (TOF)

An off-delay timer works in the reverse of an on-delay timer regarding its trigger.

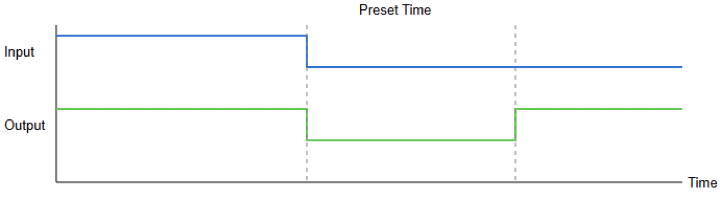

Operation

The output turns ON immediately when the input is activated. Meaning, when the input signal is OFF, the timer begins its countdown soon.

This is similar to saying, when the input falls from high to low. The output remains ON until the time expires, then it turns OFF.

Post-operation cooling. For instance, an industrial fan might be programmed with a TOF to continue running for three minutes. During this time, the machine has been powered down to dissipate heat.

Retentive On-Delay Timer (RTO / TONR)

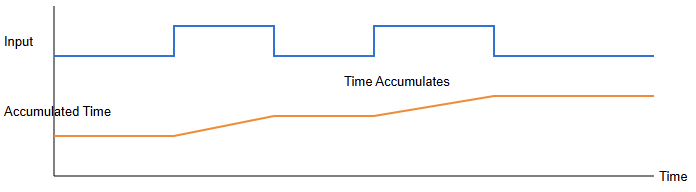

Standard timers reset their “accumulated time” to zero if the input signal is lost before the preset time is reached. A retentive timer does not.

Operation

It tracks the total time an input has been active. If the signal is interrupted, it holds the value and resumes counting.

It starts from that point when the signal returns. It requires a separate Reset instruction to clear the time.

Maintenance tracking. RTOs are used to track the total runtime of a machine to trigger a maintenance alert after 1,000 hours of actual operation.

Non-Retentive Timers

Non-retentive timers are timers that reset automatically when their input signal turns OFF. Any accumulated time is immediately reset.

After that, the timer starts from zero when the input is reactivated. Most standard on-delay and off-delay timers fall into this category.

Non-retentive timers are suitable for repetitive processes where time history is not important.

This means they are also useful for predictable processes. Their simplicity makes them easy to implement and troubleshoot.

They are commonly used in conveyor systems, basic sequencing logic, and simple interlocking applications.

Because they do not store time values, they also reduce memory usage in PLC-based systems.

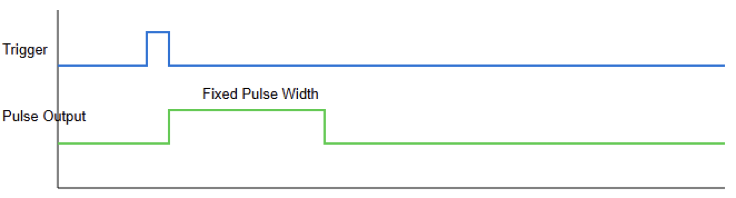

Pulse or “One-Shot” Timer (TP)

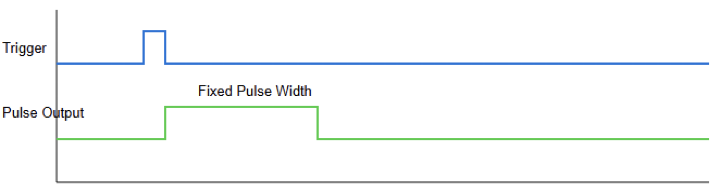

Operation

Once triggered by a brief pulse, the output stays ON for a fixed duration regardless of whether the input stays on or turns off. Packaging lines. A sensor detecting a box might trigger a TP to activate a glue sprayer for exactly 500 milliseconds.

Interval Timers

An interval timer activates its output for a fixed period immediately after the input turns ON. When the input becomes true, the output turns ON.

Then the timer begins counting. Once the preset interval expires, the output turns OFF. This occurs even if the input remains ON.

This behavior differs from that of an on-delay timer, where the output turns ON only after the delay period. Interval timers are useful when a controlled-duration action is required.

Common applications include dosing systems, where a valve must remain open for a precise amount of time. Also, protection systems, where equipment should only operate for a limited duration.

This helps to prevent overheating or mechanical stress. Interval timers are also used in spray, fill, and purge operations.

Cyclic Timers

Cyclic timers are also known as flasher timers. They work by generating repetitive ON and OFF signals.

Once enabled, the timer alternates between an ON period and an OFF period. These durations can be equal or independently adjustable.

The cycle continues as long as the enable signal remains active. Cyclic timers are used in applications requiring periodic or intermittent operation. Examples include flashing warning lights and operating pumps.

This can be done intermittently to maintain pressure, controlling agitators in mixing tanks. Also, generating clock signals for sequential logic.

Their repetitive nature makes them especially useful for signaling and warning applications.

Real-Time Clock Timers

While other timers use elapsed time, real-time clock (RTC) timers operate based on actual date and time.

They use an internal clock, often supported by a battery backup. This helps to maintain accurate time during power outages.

RTC timers allow control actions to be scheduled at specific times. It could be dates or days of the week, too.

The main application of these timers is commonly in building automation control. Also, energy management systems and infrastructure control.

Advanced and Specialized Timers

Beyond basic logic, specific industrial needs have led to specialized timing devices:

Astronomical Timers

These use geographic coordinates to calculate sunrise and sunset times, automatically adjusting schedules throughout the year. They are currently standard for automated factory perimeter lighting.

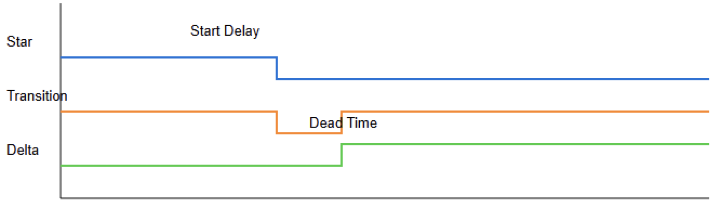

Star-Delta Timers

Specifically designed for motor starters, they transition a motor from a “star” configuration with low starting current. After a set delay, the motor switches to a “Delta” configuration for full running power.

IoT & Cloud-Integrated Timers

Emerging as a major trend in the near future, these timers are saviors for engineers. They are suitable for monitoring and adjusting timing parameters remotely.

It can be done via smartphones or centralized SCADA systems. Also, enabling AI-driven predictive maintenance.

Conclusion

This article provides a comprehensive explanation of the main types of timers used in industrial automation. It explained their operating principles, typical applications, and practical considerations.

Timers are essential building blocks in industrial automation systems. They enable precise control of delays and sequences.

They also support time-limited operations that are critical for safe and efficient process control.

Different types of timers are designed to address different control requirements.

Some provide simple on-delay and off-delay functions. Others support advanced retentive, cyclic, and real-time scheduling applications.

Understanding how each timer type operates allows engineers and technicians to design clearer and more reliable control logic. It also helps them avoid common implementation errors.

By selecting the appropriate timer for each application, automation systems can achieve improved performance and reduced equipment stress. This also leads to greater operational reliability.

Frequently Asked Questions

What is a timer in industrial automation?

A timer is a control function that changes its output based on elapsed time.

Why are timers used in automation systems?

Timers control delays, sequences, and time-dependent operations to improve safety and reliability.

What are the most common PLC timer types?

The most common types are TON (On-Delay), TOF (Off-Delay), and RTO (Retentive) timers.

What is a Timer On Delay (TON)?

A TON delays turning ON the output after the input becomes true.

What is a Timer Off Delay (TOF)?

A TOF keeps the output ON for a set time after the input turns off.

What is a Retentive Timer (RTO)?

An RTO retains accumulated time when the input turns off and resumes later.

What is the difference between retentive and non-retentive timers?

Retentive timers store elapsed time, while non-retentive timers reset automatically.

What is a pulse timer?

A pulse timer generates a fixed-duration output when triggered.

What is an interval timer?

An interval timer turns the output ON immediately and OFF after a preset time.

What is a cyclic or flasher timer?

A cyclic timer repeatedly switches the output ON and OFF.