A SCADA (Supervisory Control and Data Acquisition) system is a critical industrial control system.

It monitors and controls industrial processes in real time. It combines hardware and software components that give operators centralized visibility and control over operations.

These systems are essential across industries such as energy, oil and gas, manufacturing, and water management. They optimize efficiency, ensure safety, and support data-driven decisions.

By collecting data from many field devices, SCADA systems process and display information. This allows operators to take necessary actions from a central location.

This article explains how a SCADA system works. It breaks down its components and shows the flow of data from the field to the control room.

Evolution and Modern SCADA

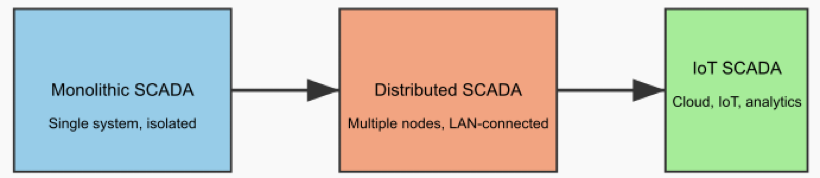

SCADA technology has evolved greatly over time. Early systems were monolithic and isolated. The second generation introduced distributed systems connected by local area networks (LANs).

Third-generation systems adopted open protocols and networking technologies. Today’s SCADA integrates IoT devices, cloud computing, and advanced analytics. This provides scalability and remote access.

Operators can monitor and control processes from anywhere in the world. Cloud-based SCADA offers greater flexibility and massive data storage.

However, the shift to open and networked systems brings cybersecurity challenges. Modern SCADA solutions must prioritize strong security measures.

The Architecture of a SCADA System

A SCADA system is not a single product. It is a framework of interconnected components working together.

It usually has a multi-layered architecture, often described as a pyramid. The base layer includes sensors and other field devices.

The next layer contains local control units such as PLCs and RTUs. These controllers collect and process data from the field. The information is then sent to a supervisory computer at a central location.

This central system uses software to process and display data on an HMI. Finally, communication networks connect all components together. This structure ensures reliable and efficient data flow and control.

Data Acquisition from Field Devices

The process begins with field devices. They are the eyes and ears of the SCADA system.

Field devices include sensors, gauges, meters, and actuators. They are spread across industrial plants or large areas.

Sensors measure physical parameters such as temperature, pressure, flow, voltage, or current. Actuators perform physical actions. They can open valves, start motors, or adjust machine settings.

This raw, real-time data is essential for monitoring the process. Without these devices, the SCADA system would be blind.

The Role of PLCs and RTUs

Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs) form the brain of the local control layer.

Both are microcomputers designed for harsh industrial environments. PLCs are used for local, real-time control inside factories.

RTUs handle control at remote sites or over large areas. Both collect data from field devices and convert analog signals into digital ones. They also execute control commands using predefined logic.

PLCs and RTUs act as bridges. They link the physical world of sensors with the digital world of central control.

Communication Networks

The communication network is the nervous system of the SCADA architecture.

It connects PLCs and RTUs to the central supervisory computers.

Communication may be wired or wireless. Wired connections often use Ethernet for speed and reliability.

Wireless links use radio, cellular, or satellite connections for remote areas. Communication protocols define how devices exchange data. Common ones include Modbus, DNP3, and IEC 60870-5.

Modern SCADA systems use TCP/IP for network-based communication. The network must be both robust and secure. This ensures data integrity and timely delivery.

The Master Terminal Unit (MTU) or SCADA Server

The Master Terminal Unit (MTU) is the central command center. It consists of one or more computers running SCADA software. The MTU gathers data from all connected RTUs and PLCs. It acts as a server that processes and archives this data.

The stored information supports historical trending and reporting. The MTU also handles alarm management. It compares incoming data with predefined limits. If a parameter goes out of range, the system triggers an alarm.

The MTU can also send control commands back to the field. This happens automatically or when an operator issues instructions.

The Human-Machine Interface (HMI)

The Human-Machine Interface (HMI) is how operators interact with the SCADA system. It provides a visual display of the entire process. HMIs present information using graphics, charts, and mimic diagrams.

An operator can quickly see the status of all equipment. For example, a pump icon might change color when it is running. Operators can issue commands using a mouse, keyboard, or touchscreen.

This allows them to start a pump or adjust flow remotely. The HMI is essential for quick decision-making and troubleshooting.

Data Processing and Analysis

SCADA systems manage large amounts of data. The data from field devices is timestamped and stored. This historical data is extremely valuable for analysis.

It allows operators to spot trends and predict potential issues.

They can perform predictive maintenance before failures occur. Reports generated from this data also support regulatory compliance. Modern SCADA systems use advanced analytics and artificial intelligence.

These tools help optimize performance and forecast future problems. The data processing layer turns raw numbers into actionable insights.

Control Operations

SCADA systems provide both supervisory and automated control. Supervisory control involves human operators. They use the HMI to issue commands based on displayed data. Automated control is managed by PLCs or RTUs.

These devices react automatically to specific conditions. For example, if temperature rises above a limit, a PLC might start a cooling fan.

This dual system ensures flexibility and reliability. Automation handles routine tasks and emergencies. Human operators focus on major issues and strategic planning.

Alarm and Event Management

Alarm management is a core function of SCADA. Operators must be alerted when something abnormal occurs. The SCADA server constantly monitors all incoming data.

If a value exceeds a predefined limit, the system triggers an alarm.

Alarms can be audible or visual. They may also have different priority levels. The system records all events, including operator actions. These logs are vital for troubleshooting and post-incident analysis.

Modern systems can also send alerts via email or text messages. This ensures quick operator response.

Integration with Other Systems

Modern SCADA systems rarely operate alone. They often integrate with higher-level enterprise systems such as MES and ERP.

This integration connects operational technology (OT) with information technology (IT).

It allows data to move smoothly across all levels of the organization. For example, SCADA production data can feed into an ERP system for inventory tracking.

When linked with MES, it can improve scheduling and quality control. This connectivity increases efficiency and data visibility.

Key Takeways: How Does a SCADA System Work?

This article studied how the SCADA system works by It breaking down its components and detailed the flow of data from the field to the control room. So, in short SCADA system is a complex technology made up of many components.

It enables remote supervision and control of industrial processes. The system gathers data from field devices such as sensors and actuators. PLCs and RTUs collect and process this data.

It then travels over communication networks to the central supervisory system. Here, the SCADA software displays the data on an HMI. Operators can monitor the process, receive alarms, and issue control commands.

Historical data is analyzed to generate reports and insights. With the rise of IoT and networked systems, SCADA continues to evolve. It remains vital for maintaining safety, efficiency, and real-time control in modern industries.

FAQ: How Does a SCADA System Work?

What is SCADA?

A system that monitors and controls industrial processes in real time.

What are the main components?

- Field devices (sensors, actuators)

- Controllers (PLCs, RTUs)

- Communication networks

- Central system with SCADA software and HMI

How does SCADA work?

Field devices collect data. Controllers process it and send it to the central system. Operators view and control processes via the HMI.

What are its key functions?

- Real-time monitoring

- Supervisory and automated control

- Data logging and trend analysis

- Remote access to processes

Which industries use SCADA?

Energy, oil & gas, water, manufacturing, and infrastructure.

How has SCADA evolved?

From isolated systems to networked, IoT-enabled, cloud-connected systems.

What are common risks?

Cybersecurity threats, integration challenges, and ensuring reliable data flow.

Can SCADA integrate with other systems?

Yes, with ERP and MES systems for better efficiency and data sharing.