In modern industrial automation, reliable communication between devices is essential.

Every process, from a simple sensor reading to a largescale production line, depends on seamless data exchange between controllers, sensors, and actuators.

Two of the most widely used Ethernet-based protocols are EtherNet/IP and Modbus TCP.

At first glance, they appear similar since both use standard Ethernet networks for communication.

However, beneath this shared foundation, they differ significantly in how they structure, transmit, and manage data.

This article details the key differences between EtherNet/IP and Modbus TCP, explaining their architectures, communication methods, performance, and best application areas.

It aims to help engineers, integrators, and system designers choose the right protocol for their specific needs based on speed, complexity, interoperability, and security.

Overview and Background

Ethernet-based communication has become the backbone of industrial control systems.

It provides high speed data exchange, easy scalability, and the ability to integrate multiple layers from field devices to enterprise networks on a single platform.

Both Modbus TCP and EtherNet/IP take advantage of these benefits but in different ways.

Modbus TCP is valued for its simplicity and openness. It builds upon the traditional Modbus protocol and adapts it to modern Ethernet networks.

WhileEtherNet/IP, on the other hand, is feature-rich and powerful. It brings advanced capabilities from the Common Industrial Protocol (CIP), enabling real-time control, motion coordination, and system wide integration.

Understanding how each protocol works is essential to designing reliable automation systems that balance cost, performance, and scalability.

Architecture and Data Model

In this section we will review an architecture and data model of each of these communication protocols.

Modbus TCP

Modbus TCP is one of the easiest industrial communication protocols to implement.

It is an open standard that encapsulates the traditional Modbus RTU frame inside a TCP/IP packet.

So, this allows it to function over Ethernet without major modifications.

Key features:

- Based on a client-server (or master-slave) communication model.

- The client initiates a request; the server processes it and sends a response.

- Data is represented in simple tables known as registers and coils.

Common data types:

- Coils: Discrete on/off values used for digital outputs.

- Input Status: Read only discrete inputs.

- Holding Registers: 16-bit read/write registers used for analog values or process data.

- Input Registers: 16-bit read-only registers used for sensor input data.

Each device on a Modbus TCP network is identified by a unique IP address. For systems connected through gateways to Modbus RTU networks, a Unit Identifier is used to route messages to the correct device.

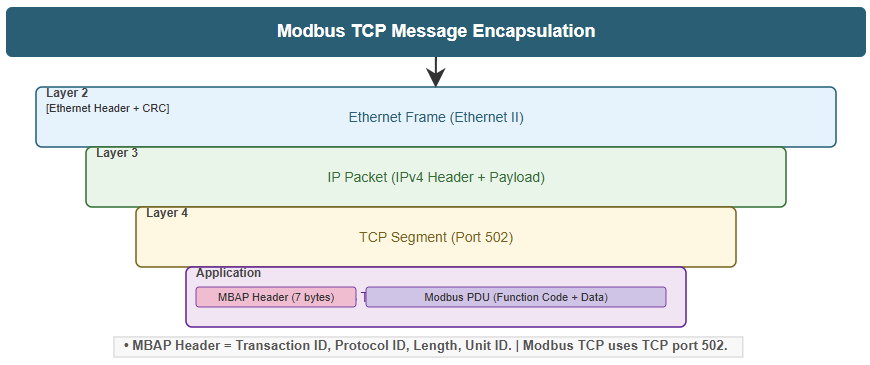

A Modbus TCP message includes:

- A 7-byte MBAPheader (Modbus Application Protocol header).

- The Protocol Data Unit (PDU), which contains the function code and data.

- The entire message is encapsulated inside a TCP/IP frame and transmitted via Ethernet.

This simple and consistent structure makes Modbus TCP highly transparent, easy to debug, and compatible with many devices and software tools.

EtherNet/IP

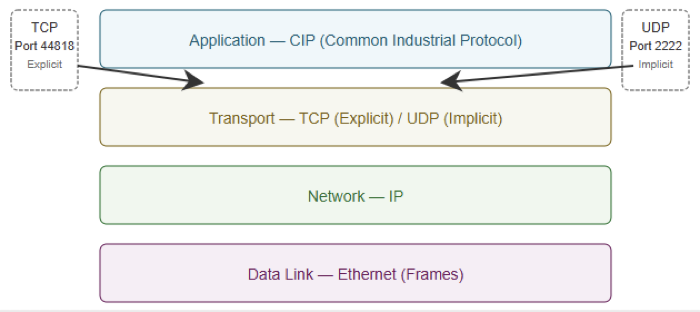

EtherNet/IP (Ethernet Industrial Protocol) is more sophisticated. It adapts the Common Industrial Protocol (CIP) to Ethernet, providing a consistent way to model data, manage devices, and control real-time operations.

Unlike Modbus TCP’s table based design, EtherNet/IP is object-oriented. Devices organize their data into logical objects, each containing multiple attributes that represent different parameters or values.

Communication models:

- ExplicitMessaging (Client/Server): Used for configuration, diagnostics, and non-time-critical data. Operates over TCP for reliable delivery.

- ImplicitMessaging (Producer/Consumer): Used for real-time I/O data exchange. Operates over UDP for high-speed, cyclic, multicast communication.

Addressing:

- Devices are identified by IP addresses.

- Specific data is accessed through a CIP path, which points to the object and attribute to be read or written.

Port usage:

- TCP port 44818 for explicit messaging.

- UDP port 2222 for implicit messaging.

Because of its object-oriented structure, EtherNet/IP supports complex applications such as synchronized motion control, advanced diagnostics, and flexible system integration.

Key Differences Between EtherNet/IP and Modbus TCP

While both protocols share Ethernet as a physical medium, their operation and capabilities differ considerably.

Main distinctions

Data Model

EtherNet/IP: Object-oriented using CIP; Modbus TCP: Simple, table based registers and coils.

Communication Style

EtherNet/IP: Producer/Consumer (implicit) and Client/Server (explicit); Modbus TCP: Client/Server only.

Real-Time Performance

EtherNet/IP: Excellent real-time behavior using UDP implicit messaging; Modbus TCP: Limited real-time capability; sequential requests can slow communication.

Addressing

EtherNet/IP: IP address plus CIP path; Modbus TCP: IP address plus Unit Identifier.

Openness

EtherNet/IP: Managed by ODVA, which may require vendor certification; Modbus TCP: Completely open and royalty-free.

Complexity

EtherNet/IP: More complex configuration and setup; Modbus TCP: Very easy to implement.

Security

EtherNet/IP: Supports CIP Security (authentication, encryption, and access control); Modbus TCP: Lacks built-in security, depends on network firewalls or VPNs.

Troubleshooting

EtherNet/IP: Requires specialized diagnostic tools; Modbus TCP: Easier to analyze and debug with standard tools.

Flexibility and Use Case

EtherNet/IP: Best for complex, large-scale systems and motion control; Modbus TCP: Ideal for simple monitoring and legacy equipment.

Performance and Reliability

Speed and Determinism

Real-time performance is one of the main criteria for choosing between these protocols.

Modbus TCP

Relies on TCP, which guarantees reliable delivery but can introduce variable delays.

Each client must wait for a response before sending a new request, which increases scan time as more devices are added.

Suitable for non-time-critical monitoring but not for synchronized control.

EtherNet/IP

Achieves faster and more deterministic performance through implicit messaging.

UDP allows multicast communication, enabling one device to send updates to many consumers simultaneously.

This model reduces network load and increases efficiency for real-time control.

Traffic can also be prioritized using Quality of Service (QoS) to maintain predictable timing.

Reliability and Error Handling

Both rely on Ethernet and TCP/IP layers for basic reliability.

However, EtherNet/IP adds extra diagnostic and error-handling capabilities.

Modbus TCP:

- Simplicity means fewer error management features.

- TCP ensures packet delivery, but application-level fault handling is minimal.

EtherNet/IP:

- Includes mechanisms for connection supervision, timeouts, and controlled disconnections.

- Explicit messages can terminate safely if errors occur.

- Implicit connections can detect timeouts and re-establish communication automatically.

Security Considerations

As industrial systems become more connected, cybersecurity is critical.

Modbus TCP:

- Designed in the 1990s when network threats were minimal.

- Does not include built-in authentication, authorization, or encryption.

- Vulnerable to attacks if exposed to public networks.

- Recommended protection includes network segmentation, VPNs, and firewalls.

EtherNet/IP:

- Incorporates CIP Security, which aligns with modern industrial cybersecurity standards.

- Features include:

- Authentication: Verifies the identity of communicating devices.

- Encryption: Secures the data transmitted between devices.

- Access Control: Restricts communication to approved connections.

- These features make EtherNet/IP suitable for applications where security and data integrity are mandatory.

Implementation and Configuration

Modbus TCP

One of Modbus TCP’s greatest strengths is its simplicity.

It can be configured within hours by engineers familiar with TCP/IP networks.

Typical setup steps include: Assigning IP addresses to devices, mapping registers for reading and writing data and finally, defining the function codes required by the client.

Because of its simplicity, Modbus TCP is ideal for small or medium-sized projects, quick prototyping, and systems where minimal configuration time is preferred.

EtherNet/IP

EtherNet/IP offers much greater flexibility but requires more effort to configure.

It involves defining objects, services, and I/O connections within the CIP framework.

Specialized tools from vendors such as Rockwell Automation are often used to configure and diagnose networks.

While the initial setup takes longer, the reward is advanced performance, scalability, and tight integration between devices.

Hardware and Interoperability

Both protocols use standard Ethernet hardware such as switches, routers, and network interface cards.

However, their interoperability and hardware requirements differ slightly.

Modbus TCP:

- Uses standard, low-cost Ethernet components.

- Widely supported across vendors and compatible with older Modbus RTU devices via gateways.

- Excellent for mixed environments that include legacy systems.

EtherNet/IP:

- Also based on Ethernet, but devices may require more processing power to handle CIP messaging and real-time tasks.

- Certified by ODVA, ensuring consistency and interoperability between manufacturers.

- Preferred in systems built around Rockwell Automation or similar high-end control environments.

Choosing the Right Protocol

The decision between EtherNet/IP and Modbus TCP depends on project needs, device compatibility, and performance expectations.

Choose Modbus TCP when:

- You are integrating legacy or simple devices.

- The system involves basic data acquisition or monitoring.

- Cost and ease of implementation are top priorities.

- Real-time performance is not critical.

- You need a protocol that works across many vendors with minimal setup.

Choose EtherNet/IP when:

- The application demands high-speed or synchronized control.

- The network involves robotics, motion systems, or large-scale automation.

- You need strong security and diagnostic features.

- You require seamless integration across multiple system levels using CIP.

- Long-term scalability and performance are essential.

Key Takeaways: The Difference between Ethernet IP and Modbus TCP

This article detailed how both EtherNet/IP and Modbus TCP play vital roles in modern industrial communication.

They share Ethernet as a common platform but serve different purposes depending on system complexity and performance needs.

Modbus TCP stands out for its simplicity, openness, and low cost. It is well suited for basic monitoring, energy management, and legacy system integration.

Its straightforward structure makes it easy to implement, maintain, and troubleshoot with minimal technical effort.

EtherNet/IP excels in speed, flexibility, and security. Its object-oriented model, support for real-time communication, and advanced protection features make it ideal for high-end automation, motion control, and large distributed systems.

Choosing between the two depends on balancing performance, complexity, security, and budget.

For small or cost-sensitive projects, Modbus TCP offers a reliable and simple solution.

On the other hand, for large, performance critical environments, EtherNet/IP provides the power, scalability, and precision required by modern industries.

FAQ: The Difference between Ethernet IP and Modbus TCP

What is EtherNet/IP?

EtherNet/IP adapts the Common Industrial Protocol (CIP) to Ethernet, supporting object-oriented data and real-time control.

What is Modbus TCP?

Modbus TCP wraps the Modbus protocol in a TCP/IP packet, enabling Modbus messaging over Ethernet.

Which protocol supports real-time control better?

EtherNet/IP, via its UDP-based implicit messaging, provides more deterministic performance.

Which is simpler to implement?

Modbus TCP is simpler, with fewer layers and a straightforward request/response model.

What about security?

EtherNet/IP supports CIP Security (authentication, encryption), while Modbus TCP lacks built-in security.

How do they address data?

EtherNet/IP uses IP + CIP path to reach objects/attributes. Modbus TCP uses IP + Unit Identifier to map to registers.

Are both open standards?

Modbus TCP is fully open and royalty-free. EtherNet/IP is governed by ODVA and may require compliance or certification.

When should I choose Modbus TCP?

Use Modbus TCP for simple data acquisition, legacy device support, or when cost and ease matter more than performance.

When is EtherNet/IP preferred?

Choose EtherNet/IP for high-speed control, synchronized operations, and complex automation with security needs.