Redundancy in industrial automation refers to the use of backup or standby systems.

These systems automatically take control when the main system experiences a fault or failure. This approach ensures continuous operation and prevents expensive downtime.

It is essential for industries requiring uninterrupted production, such as oil and gas, pharmaceuticals, and power generation.

By designing systems with redundancy, organizations can enhance reliability and maintain safety. They can also reduce financial and operational risks.

This article explores how redundancy improves system performance, the different redundancy architectures used, and its overall importance in maintaining efficient industrial processes.

The importance of redundancy

Industrial operations are expensive. Any production halt can result in substantial financial loss. In certain industries, a single process interruption can destroy the entire product.

This results in wasted raw materials and labor. For instance, in the pharmaceutical industry, if a critical chemical reaction stops mid-process, the entire batch can be rendered unusable.

This can happen due to contamination or instability. Similarly, in semiconductor fabrication, an unexpected halt can ruin hundreds of chips. This leads to substantial financial loss and delayed production schedules.

Other processes, such as steel or glass manufacturing, may require several hours or even days to restart. For example, reheating a steel furnace to the correct operational temperature is time intensive.

It also consumes large amounts of energy. This makes it vital to avoid unexpected stoppages.

Such stoppages could impact productivity, energy efficiency, and safety. Redundancy eliminates single points of failure.

These are specific components whose malfunction can halt the entire system. Backup systems allow operations to continue. They take over if a primary component fails. This helps maintain production and ensures worker safety.

Redundancy is not just about hardware. It also extends to software, networks, and communication protocols. This ensures a complete safety net for industrial processes.

Types of redundancy architecture

Redundancy can be implemented at various levels and in several ways. The right approach depends on the criticality of the process. In addition, system complexity, and cost considerations.

Understanding the types of redundancy is essential for designing reliable automation systems.

Hot standby redundancy

- Represents the highest level of redundancy in industrial automation.

- Designed for processes where even a millisecond of downtime is unacceptable. Examples include power generation, chemical processing, or oil refining.

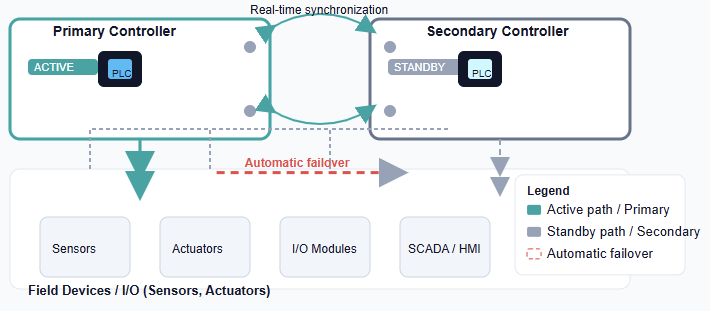

- Both primary and backup systems operate simultaneously. They remain fully synchronized in real-time.

- If the primary system fails, the backup immediately assumes control. There is no interruption to the process.

- Switchover is seamless, ensuring uninterrupted operation.

- This setup may require advanced synchronization software, specialized failover mechanisms, and highly trained operators.

Hot standby is often preferred in mission critical environments. In nuclear power plants, controller redundancy is used to protect critical systems. It ensures these safety systems continue operating even if a primary controller fails.

This prevents catastrophic events. Similarly, in high speed manufacturing lines, hot standby PLCs allow production to continue without losses due to unexpected failures. The next diagram shows hot standby redundancy.

Warm standby redundancy

- Suitable for systems where a brief interruption is acceptable.

- The backup system is partially active. It may be powered on but not fully synchronized.

- When the primary system fails, the backup takes a short time to assume control.

- An arbitration mechanism is typically required to manage the switchover.

- The transition introduces minor downtime. This is often acceptable in less time-sensitive processes.

For example, in water treatment plants, warm standby systems are used for pumps or chemical dosing controllers. A momentary outage may occur during switchover. However, it does not compromise overall process safety or water quality.

Warm standby balances cost and reliability. It requires less infrastructure than hot standby while still providing protection against failures.

Cold standby redundancy

- The most basic and cost-effective form of redundancy.

- Used in processes where temporary downtime is not critical.

- A pre-configured spare component is available but requires manual intervention by an operator.

- The switchover takes longer than hot or warm standby systems. It may involve physically connecting components or activating backup software.

Cold standby is often found in smaller facilities or non-critical production lines. For instance, in small scale packaging or assembly operations, a spare PLC or drive is available but inactive. It remains unused until it is needed.

While less expensive, cold standby relies heavily on human response. This introduces potential delays or errors during critical failures.

Areas of redundancy in industrial automation

Redundancy is not limited to a single component. It can be applied across various parts of an industrial system. This enhances overall reliability and resilience. Common areas include controllers, networks, power systems, I/O modules, and supervisory systems.

Controller redundancy

- Controllers are the “brains” of automation systems. They execute logic to manage processes.

- Failure of a controller can halt an entire production line or process.

- Redundancy is achieved by using multiple controllers. One acts as primary and the others as backups.

- Hot standby is typically preferred for critical controllers. This ensures instant switchover in case of failure.

Controller redundancy is essential in industries like oil and gas. Automated pipeline management systems continuously monitor flow, pressure, and leaks.

Backup controllers ensure that monitoring and control continue even during hardware failures. This prevents accidents and operational disruptions.

Network redundancy

Industrial networks connect sensors, controllers, actuators, and supervisory systems. Redundant networks create multiple communication paths. If one link fails, data continues to flow through alternate paths.

Self-healing ring topologies are commonly used. For example, in smart factories, production lines rely on networked robots and conveyor systems. A redundant network ensures that even if a single switch or cable fails, the production line continues.

This prevents costly stoppages. Network redundancy also supports remote monitoring and predictive maintenance.

Operators can respond to potential issues before they escalate. The following figure depicts self-healing ring network.

Power system redundancy

Continuous power supply is vital in automation. Redundant power setups include dual supplies for critical controllers or devices.

They also include UPS systems for short-term support. Standby generators provide extended power in case of longer outages.

In semiconductor or pharmaceutical manufacturing, even brief power loss can damage products.

It can also require discarding the entire batch. Redundant power ensures continuous operation. This protects both production quality and safety.

I/O redundancy

I/O modules connect controllers with field devices such as sensors, actuators, and valves. Redundant I/O ensures that backup modules automatically take over if primary modules fail. This guarantees that critical field operations continue without interruption.

For instance, in a chemical processing plant, redundant I/O ensures continuous monitoring and control of temperature, pressure, and flow. This prevents unsafe operating conditions and environmental hazards.

SCADA and HMI redundancy

SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface) systems are essential for real-time monitoring and control. Redundant SCADA architectures involve primary and standby servers.

They remain synchronized at all times. If the primary server fails, the backup immediately assumes control. Operators maintain full access and visibility.

This redundancy is vital in energy distribution. Continuous monitoring of grid conditions is critical.

It also supports remote operations. Personnel can respond to alarms or adjust parameters without interruption.

Benefits of implementing redundancy

Redundancy offers several key advantages. It enhances reliability and availability because backup systems minimize downtime and keep production running continuously.

It also improves safety. Redundant systems help prevent accidents and protect equipment in hazardous environments. Redundancy supports business continuity. Production can continue even if hardware or software fails, which helps avoid financial losses.

It provides maintenance flexibility. Systems can be serviced or upgraded without stopping operations.

Additionally, redundancy protects critical process data. Backup systems ensure that important information is preserved during failures.

The combination of these benefits makes redundancy essential. This is especially true in industries where uptime directly affects revenue, safety, and regulatory compliance.

Challenges and considerations

Implementing redundancy also comes with challenges. One major factor is higher cost. Additional hardware, software, and infrastructure increase the upfront investment required.

System complexity is another concern. More components mean careful integration, monitoring, and testing are needed to ensure everything works correctly.

Maintenance requirements are also higher. Redundant systems must be regularly tested to confirm they function properly when needed.

Software compatibility can be an issue. Automation software must fully support redundancy and failover mechanisms for the system to work as intended.

There is also the risk of residual single points of failure. Careful system design is necessary to ensure all critical components are backed up.

Despite these challenges, the benefits usually outweigh the costs. Industries that deal with high value or hazardous processes gain significant risk reduction and improved operational reliability by implementing redundancy.

Use Cases

Redundancy is widely applied across sectors.

- Oil and gas: Redundant servers manage pipeline monitoring, leak detection, and process control. Failures are mitigated instantly without interrupting operations.

- Automotive manufacturing: Backup PLCs prevent costly line stoppages. This helps maintain just-in-time production schedules.

- Power generation: Redundant controllers, networks, and power systems ensure uninterrupted electricity production. This prevents blackouts and supports grid stability.

- Pharmaceuticals: Redundant SCADA and I/O systems protect sensitive production processes. They also ensure compliance with stringent regulatory standards.

These real-world applications demonstrate how redundancy reduces risk, protects assets, and maintains operational excellence.

Conclusion

This article detailed how redundancy in industrial automation strengthens system reliability and availability. It does this by duplicating critical components and eliminating single points of failure.

Redundancy can be implemented in controllers, networks, power systems, I/O modules, and supervisory systems.

Hot, warm, or cold standby strategies are chosen based on process importance, cost, and acceptable downtime.

Implementing redundancy increases system complexity and upfront costs. However, the benefits in terms of safety, uninterrupted operations, and business continuity are substantial.

As industrial automation technology continues to evolve, redundancy will remain a foundational principle.

It ensures resilient, fault-tolerant systems that can withstand failures and maintain operational excellence.

FAQ: What is Redundancy in Industrial Automation?

What does “redundancy” mean in the context of industrial automation?

Redundancy means having backup systems that take over if the main system fails. It ensures continuous operation and reliability.

Why is redundancy important in industrial automation?

It prevents costly downtime and protects against production loss. It also improves safety in critical processes.

What are the common types or levels of redundancy used?

Hot standby runs a full backup in parallel. Warm standby partially activates the backup. Cold standby requires manual activation of a spare component.

Where in an automation system is redundancy typically applied?

It is used in controllers, networks, power supplies, I/O modules, and SCADA/HMI systems. This keeps processes running if one part fails.

What are the main benefits of implementing redundancy?

It increases uptime, ensures safety, allows maintenance without stopping production, and protects data and equipment.

What challenges or tradeoffs come with implementing redundancy?

Redundancy adds cost, complexity, and maintenance needs. Careful design is needed to avoid remaining single points of failure.

How can one decide what level of redundancy to implement?

The choice depends on process criticality, acceptable downtime, cost, and complexity. High-criticality systems usually use hot standby; less critical systems may use warm or cold standby.