Process control automation is a fundamental discipline. It is used in modern industrial operations.

It focuses on regulating and maintaining process variables. These variables remain within desired limits. This ensures efficient, safe, and consistent production.

Industries such as oil and gas rely on automation. Pharmaceuticals and manufacturing use automated control systems.

Power generation and water treatment also depend on it. These systems reduce human intervention and improve reliability.

Automation becomes possible by the addition of sensors, controllers, actuators, and software, it enables continuous monitoring and real-time adjustments.

These systems help industries achieve higher productivity. They also improve product quality and safety standards. Operational risks and downtime are significantly minimized.

This article studies the fundamentals of process control automation. It also examines components, strategies, and system architectures.

Communication methods and industrial applications are discussed. In addition, challenges, benefits, and finally, future trends are also explored.

What is process control automation?

Process control automation refers to automated process management. It uses control systems and advanced technologies.

These processes involve variables such as temperature and pressure. Flow rate, level, speed, and chemical composition are included.

The primary goal is maintaining predefined setpoints. This occurs despite disturbances or changing conditions.

Automation replaces or assists manual control methods. It uses programmed logic and feedback mechanisms.

Operators define desired outcomes for the process. The control system executes corrective actions automatically.

Continuous human involvement is not required. This approach increases accuracy and repeatability.

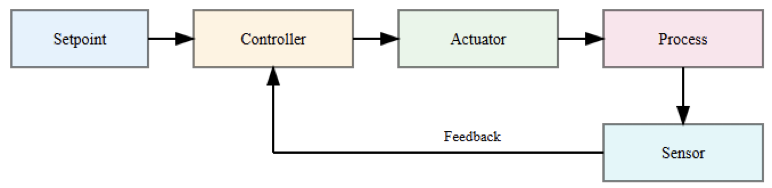

It also improves overall system stability. The following figure illustrates a basic block diagram of a process control system. It includes a process, sensor, controller, and actuator.

Key Components of Process Control Automation

Sensors and Transmitters

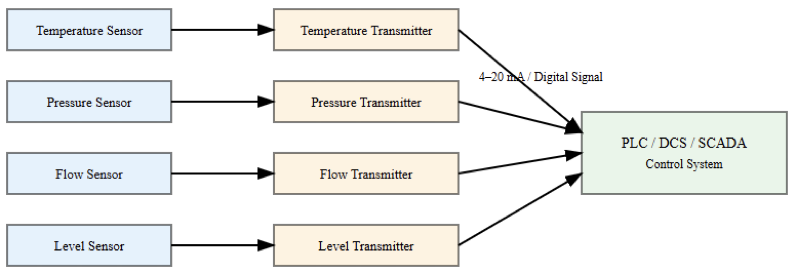

Sensors are the foundation of control systems. They detect physical process parameters. These parameters include temperature, pressure, flow, and level. Transmitters convert raw measurements into electrical signals.

These signals are standardized for controllers. Common formats include 4–20 mA signals. Digital communication protocols are also used.

Accurate sensing ensures reliable feedback. This is critical for stable control performance.

Common industrial sensors include thermocouples and RTDs. Pressure transducers and flow meters are also used.

Level switches are commonly applied. The figure below shows a typical diagram of industrial sensors connected to transmitters.

Controllers

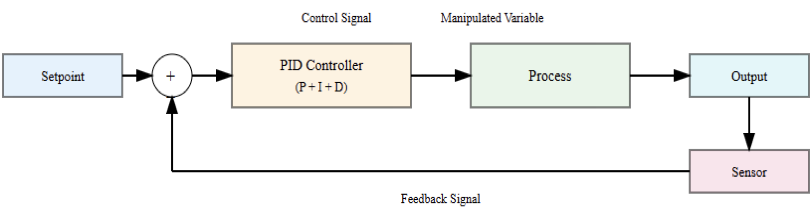

Controllers process input signals from sensors. They compare signals with desired setpoints. Based on this comparison, control action is determined.

The most widely used control algorithm is PID. It represents proportional, integral, and derivative actions.

Controllers may be implemented in PLCs. They may also be implemented in DCS platforms. Standalone controllers are another option.

Their role is central to process stability, and efficiency is also maintained. The next figure depicts a diagram of the PID controller structure with a feedback loop.

Actuators and Final Control Elements

Actuators execute actions determined by controllers. These actions physically influence the process. They adjust valves, motors, dampers, or heaters.

Final control elements convert signals into motion, where electrical or pneumatic signals are commonly used.

Examples include control valves and VFDs. Solenoids and motorized dampers are also common.

Proper actuator selection ensures smooth operation, and responsive process control is achieved.

Types of Process Control Strategies

Open-Loop Control

Feedback is not necessary when open-loop control is used. The system operates without output measurement. The controller sends predefined commands. Actual process output is not measured.

This method is straightforward and economical. However, its accuracy is limited. Disturbances cannot be compensated. This technique suits non-critical processes. High precision is not required.

Closed-Loop Control

Closed-loop control uses sensor feedback. The process is continuously adjusted.

The controller compares the output with the setpoint. Deviations are corrected automatically.

This strategy is widely used in industry. It offers reliability and adaptability. PID control is the most common method. It is widely applied in process industries.

Advanced Control Strategies

Advanced control techniques include advanced process control (APC) methods. These include predictive and adaptive control. Fuzzy logic control is also used. These methods handle complex processes effectively.

Multivariable systems benefit greatly. Traditional PID control is often insufficient. This is why APC is applied in large-scale processes. Optimization and constraint handling are critical.

Process Control Automation Architectures

PLC-Based Systems

PLC-based automation is widely used. It supports discrete and batch processes. PLCs are robust and fast, and they operate well in harsh environments. They are commonly used in packaging systems.

Assembly lines rely on PLCs, and material handling systems also use PLC control. PLCs communicate through I/O modules.

Sensors and actuators are directly connected. Control logic is programmed using ladder diagrams. Function blocks are also used.

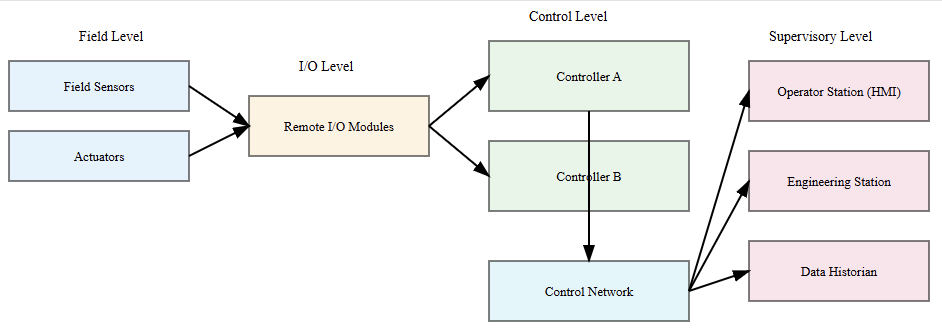

Distributed Control Systems

They are famously known as DCS. The DCS architectures support continuous processes. Refineries and chemical plants use them.

Control functions are distributed across controllers. These controllers communicate via networks.

DCS provides high system availability, and redundancy is built into the architecture. Centralized monitoring is achieved, and operator workstations are used.

The upcoming figure demonstrates DCS architecture. It shows distributed controllers and operator stations.

SCADA Systems

SCADA systems focus on supervisory control. Monitoring is performed over large areas. They are commonly used in utilities.

Pipelines and water treatment plants also use SCADA. SCADA systems collect remote data.

Field devices transmit operational information. Operators view data through graphical interfaces.

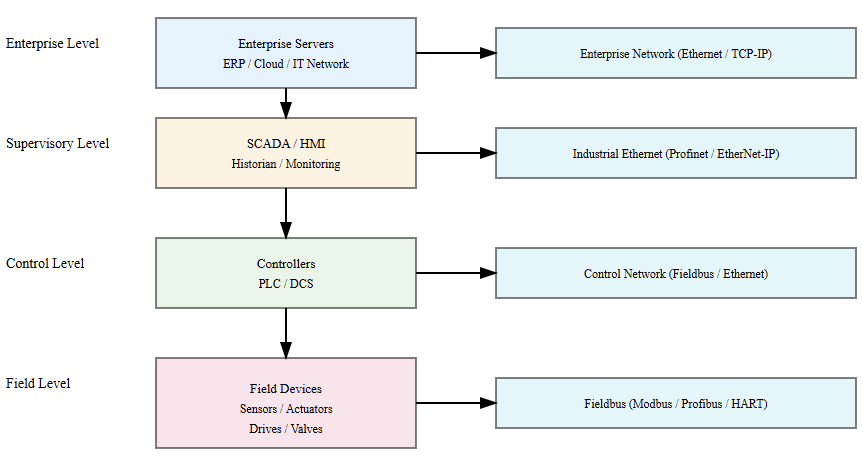

Role of Communication Protocols

Communication protocols enable data exchange. Devices communicate efficiently across systems.

These include field devices and controllers. Supervisory systems are also connected. Common protocols include Modbus and Profibus.

HART and EtherNet/IP are widely used, and OPC UA is increasingly adopted. Modern systems rely on industrial Ethernet.

Wireless communication is also growing, and real-time monitoring and diagnostics are supported.

Benefits of Process Control Automation

Process control automation offers many advantages. Industries benefit significantly. Process consistency and quality are improved.

Human error is reduced, and automation enhances operational safety. Operator exposure to hazards is minimized.

Energy efficiency is improved through optimization. Control strategies are continuously refined.

Predictive maintenance becomes possible. Real-time diagnostics are provided, and operating costs are reduced. Plant reliability is increased.

Challenges in Process Control Automation

Despite benefits, challenges remain. Automation systems can be complex. System integration is often difficult.

Multiple vendors increase complexity. Cybersecurity risks have increased. Network connectivity exposes vulnerabilities.

Initial investment costs may be high. Skilled personnel are required. Design, tuning, and maintenance demand expertise. Poor tuning can cause instability. Performance may be reduced.

Applications of Process Control Automation

Process control automation is widely applied. Many industries depend on it. Oil and gas processes use automated control.

Pressure and flow are regulated, and temperature is controlled during refining. Power plants use automation extensively.

Boilers and turbines are controlled. Generators operate under automated systems. Strict quality compliance is ensured in pharmaceutical production because automation plays a key role. Water treatment plants use automated filtration. Dosing and distribution are controlled.

Future Trends in Process Control Automation

The future is driven by digitalization. A key role is played by Industry 4.0, and IoT integration enables remote monitoring.

Advanced data analytics are applied. Artificial intelligence is increasingly used. Machine learning supports predictive control.

Fault detection capabilities are enhanced, plus cloud-based systems are gaining popularity.

Digital twins support simulation and optimization. Efficiency and flexibility will improve. Decision-making will be enhanced.

Key Takeaways: What is process control automation?

This article studied process control automation concepts. Components and applications were examined. Process control automation ensures reliable operation.

Safety and efficiency are improved, plus common devices: sensors, controllers, and actuators work together.

Communication networks enable coordination. Precise control and consistent quality are achieved.

Challenges such as cybersecurity remain. System complexity must be managed. Continued innovation helps overcome these issues

Industries are growing smarter and more connected. Automation continues to drive progress. Productivity and sustainability will continue to improve.

FAQ: What is process control automation?

What is process control automation?

It is the automatic control of industrial processes.

Why is process control automation used?

To improve safety, efficiency, and consistency.

What does it control?

Variables like temperature, pressure, flow, and level.

Where is it commonly applied?

In oil and gas, power, water, and manufacturing.

What are the main components?

Sensors, controllers, actuators, and software.

How does it work?

It measures, compares, and adjusts process variables.

What control method is most common?

Closed-loop control using PID algorithms.

Which systems are used?

PLC, DCS, SCADA, and HMI systems.