Pneumatic piston actuators remain the backbone of industrial movement due to their resilience and speed.

They are commonly used to convert compressed air into controlled mechanical motion. This motion is usually linear.

It is applied to tasks such as operating valves and moving machine parts. It also supports repetitive actions on production lines. Pneumatic piston actuators are widely chosen, simply because of their simple design.

Also, because of their reliable performance. They are preferred where speed, safety, and consistency are important.

They also have extraordinary performance in demanding environments. These include dusty, humid, or potentially explosive areas.

Understanding their operation is critical. This is for all engineers and technicians working with automated systems.

This article explains what pneumatic piston actuators are. It also explains how they work, their components, and typical applications.

What is a pneumatic piston actuator?

A pneumatic piston actuator is a mechanical device that generates linear motion. It uses compressed air as its energy source. It consists of a cylindrical body. Inside this cylinder is where pressure is applied.

Then, if this condition is satisfied, a piston moves back and forth. Afterwards, the compressed air enters the cylinder.

This exerts a force on the piston surface. As a result, a force that moves the piston in a straight line is created.

This movement is transmitted through a piston rod. The rod drives an external mechanism.

These actuators are often referred to as pneumatic cylinders. They are widely used in automation systems.

They are suitable for moderate force and fast response. They also support repetitive motion.

Their straightforward construction makes them easy to install and maintain. This simplicity explains their widespread industrial use.

Basic Operating Principle

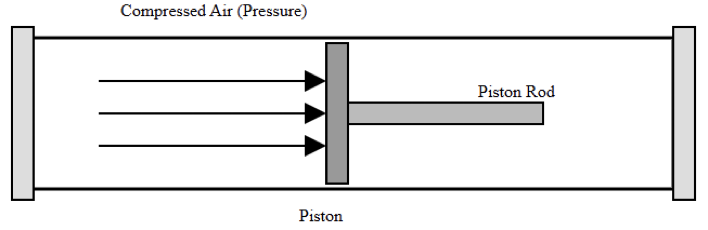

The operation of a pneumatic piston actuator is based on a simple relationship. It depends on three factors.

These factors are first, air pressure; second, surface area; and last, force. Pressure is created on one side.

This pressure creates a force on the piston when compressed air enters the cylinder. The force and the piston’s effective area are proportional. Once this force exceeds friction and external load, the piston begins to move.

The movement direction depends on which side receives compressed air. Directional control valves manage this airflow.

The piston extends or retracts because it is allowed by these valves. Simultaneously, air flows out through the opposite side.

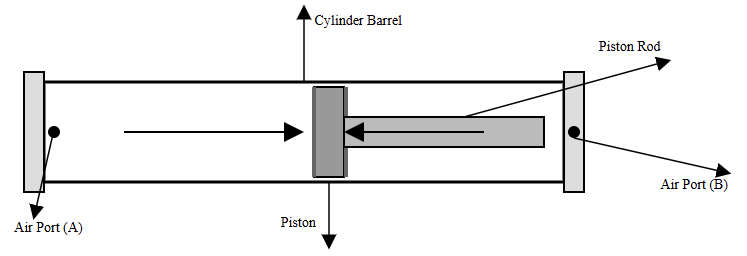

This exhaust enables smooth and controlled motion. This principle allows pneumatic actuators to deliver fast and repeatable movement. The following figure illustrates air pressure acting on a piston within a cylinder.

Main Components of a Pneumatic Piston Actuator

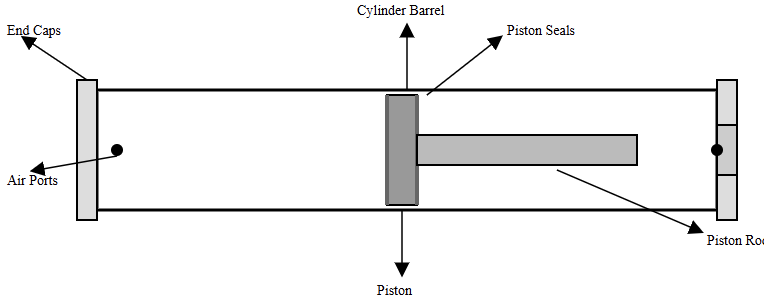

A pneumatic piston actuator has a number of key components. These parts work together to produce reliable motion.

The cylinder barrel forms the main body. It is designed for the piston to move smoothly in it. For this reason, it has a smooth internal surface.

Aluminum or steel is typically used for the construction of the barrel. They use these materials because they ensure strength and durability.

Furthermore, inside the cylinder, there are two chamber spaces. These chambers are within the piston.

Seals around the piston prevent air leakage. They also maintain pressure efficiency. An illustration of how air pressure acts on a piston within a cylinder is shown in the figure below. It transfers motion to the external load. End caps close both cylinder ends.

They contain air ports, seals, and rod guides. Together, these components ensure long service life.

The next figure depicts a cross-sectional diagram. This diagram shows a pneumatic piston actuator with labeled components.

How a Pneumatic Piston Actuator Works

A control valve is used to supply compressed air in a typical double-acting system. Air entering one chamber causes the piston to extend as air from the opposite chamber is released. To reverse the movement, the valve changes position.

Air then enters the opposite chamber. This causes the piston to retract. Flow control valves are often added to regulate piston speed. They control the exhaust airflow. Position sensors may also be installed.

These sensors detect piston location. Feedback is sent to a PLC or controller. This integration enables precise sequencing and automation.

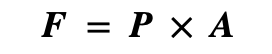

How it Works: Mathematically

The operation relies on a pressure difference across the piston. Compressed air enters through an inlet port. It exerts pressure on the piston surface, and the force generated can be calculated as shown below

Motion soon begins once the above-mentioned force exceeds load resistance and friction.

The piston and rod travel along the cylinder axis, while used air is discharged through an exhaust port. This continuous air exchange enables controlled linear motion.

Types of Pneumatic Piston Actuators

Pneumatic piston actuators are generally classified into two main types. These are single-acting and double-acting actuators.

The selection depends on application requirements. Force, control, precision, and safety are key factors.

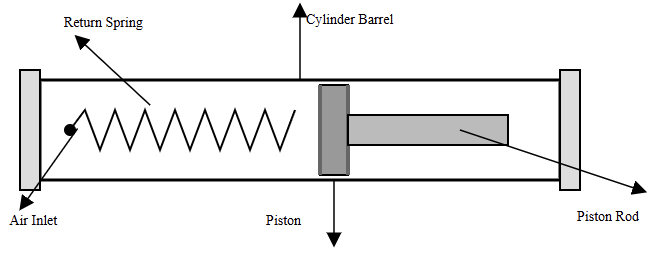

Single-Acting Pneumatic Actuator

Only one direction of movement is produced in a single-acting pneumatic actuator. Compressed air provides the driving force. A mechanical spring returns the piston when air is removed.

This design is compact and simple. It is suitable for fail-safe applications. However, usable force is limited.

Part of the force works against the spring. The upcoming diagram indicates a single-acting cylinder showing an internal return spring.

Double-Acting Pneumatic Actuator

Unlike a single-acting one, a double-acting pneumatic actuator moves the piston in both directions.

Compressed air drives extension and retraction. No return spring is required. Air alternates between both chambers.

This design provides a higher force. It also improves speed control and positioning accuracy.

Double-acting actuators are widely used in industry because of the aforementioned reasons.

Force, Stroke, and Speed Characteristics

The force produced depends on air pressure and piston area. Increasing either parameter increases the output force.

Stroke length is the distance the piston travels. It is determined by cylinder design and application needs.

Actuator speed depends on airflow rate and load conditions. Excessive speed can cause mechanical shock.

Flow control devices help prevent this issue. Proper calculation of force, stroke, and speed ensures reliable performance.

Common Applications

Pneumatic piston actuators are used across many industries. In manufacturing, they handle material movement.

They also perform clamping and positioning tasks. In process industries, they operate control valves. These valves regulate fluid flow.

They are common in packaging equipment. In addition, food and beverage plants rely on them.

Automotive assembly lines also use them extensively. Their safe operation suits hazardous environments.

Furthermore, chemical plants and oil facilities benefit from this capability. In smart factories using IoT-enabled actuators.

This is crucial for real-time monitoring of air usage and performance. Lastly, in material handling for driving gates on conveyor belts. This is useful for sorting parcels in logistics hubs.

Advantages and Limitations

Simplicity in construction and speed in response. These are the very crucial uniqueness of pneumatic piston actuators.

They require relatively low maintenance. They are cost-effective, and they perform well in clean environments.

Without a doubt, they also work reliably in harsh environmental conditions. Using compressed air eliminates electrical sparks.

However, air compressibility reduces positioning accuracy. It leads to the limitation of high-precision applications.

Energy efficiency is also lower, plus compression losses are unavoidable. Pneumatic actuators remain widely used despite the mentioned cons. Their benefits often outweigh their limitations.

Conclusion

The present article addresses what pneumatic piston actuators actually are. Furthermore, it studied how they work, their main parts, and components. And finally, the typical applications were analyzed.

The importance of pneumatic piston actuators in industrial automation is fantastic. They provide reliable linear motion using compressed air.

Their ability to convert simple compressed air into a powerful mechanical force ensures they are both reliable and versatile

Their operation is based on simple physical principles. At the same time, they offer flexible design options.

Single-acting and double-acting types support different requirements. Engineers can select designs based on safety and force needs.

Precision may be limited in some cases. Not bad to double-check the optimal, may not be the best.

Nevertheless, speed and durability make them indispensable. And most importantly, the reliability.

A clear understanding of these actuators improves system design and automation performance.

Frequently Asked Questions

What is a pneumatic piston actuator?

A pneumatic piston actuator is a device that uses compressed air to create mechanical motion.

What motion do these actuators provide?

Most piston actuators provide linear motion, meaning the piston moves straight back and forth.

However, the output motion can be converted to rotation using mechanisms like rack-and-pinion or vane systems when needed.

What are the air ports on a double-acting cylinder?

Air ports are the inlet/outlet holes on each end of the cylinder. Pressurized air enters through these ports to push the piston one way or the other.

Why are springs used in single-acting actuators?

In single-acting actuators, air only powers the piston in one direction. A mechanical spring returns the piston to its original position when the air pressure is released. This provides a simple fail-safe return motion.

What forces determine the output of a pneumatic actuator?

The force generated equals air pressure × piston area. Higher air pressure or a larger piston surface produces more force to move loads.

What are common applications for these actuators?

Pneumatic piston actuators are widely used to control valves, operate conveyors, clamp parts, and move machine components in industries such as manufacturing, water treatment, and process control.

What are the advantages of pneumatic piston actuators?

They are simple, fast, and reliable. They use clean compressed air, have few moving parts, and are easy to maintain. They also work well in harsh or hazardous environments.

What are the limitations of pneumatic piston actuators?

Their positioning accuracy is lower than that of electric actuators due to air compressibility.

They also require a supply of compressed air, and energy efficiency is reduced because of air compression losses.

How does air pressure affect actuator performance?

Higher air pressure increases force and can improve speed and responsiveness. However, system design must also consider seals, valve control, and load requirements to avoid leakage and ensure consistent performance.