The demand for precise fluid management is crucial in many applications. For instance, the basic one is water. So, accurately measuring water levels is essential in many engineering systems.

Applications may vary from simple household water tanks to industrial processes. Traditional methods include float switches and pressure sensors.

However, these methods may suffer from wear or mechanical failure. Capacitive water level sensors offer a reliable alternative.

They operate without moving parts. They provide continuous measurement. They are also suitable for harsh environments.

Capacitive water level sensors are widely used today. They appear in water treatment, HVAC, agriculture, and consumer electronics. Their popularity comes from simplicity and durability.

This article explains what a capacitive water level sensor is. It also describes how it works. Construction, operating principles, advantages, limitations, and applications are discussed in detail.

Capacitive Water Level Sensor: Definition

A capacitive water level sensor is a device used to detect the liquid level. It works by measuring changes in capacitance.

These changes occur as the water level varies. The sensor does not require direct contact with the liquid.

In many designs, the sensing element is placed outside the container. The working principle of the sensor is the conductive nature of water. Compared to air, water contains a higher dielectric constant.

As the water level rises or falls, the effective capacitance changes. This change is processed by electronics. The result is a level indication. The output may be analog or digital.

Key Components

- Sensing Electrode: The primary probe that interacts with the medium.

- Reference Electrode: Forms the second plate of the capacitive system and can be implemented as a rod or as the container itself.

- Insulating Coating: This part is often made of polytetrafluoroethylene (PTFE) or glass. Its main purpose is to prevent short-circuiting situations. The process takes place when measuring conductive liquids like salt water.

- Signal Processing Unit: Amplifiers and filters are used to convert the capacitance data into a standardized output.

Basic Concept of Capacitance

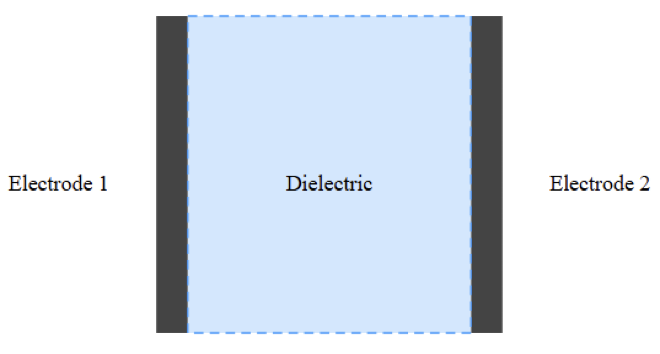

Capacitance is the ability to store electrical charge. It exists between two conductive surfaces (a parallel plate capacitor). These surfaces are separated by an insulating material. This material is called a dielectric.

Capacitance depends on three factors. These are plate area, separation distance, and dielectric constant. The basic formula is

Where:

C: Capacitance

ϵ: The dielectric constant.

A: The surface area of the plates.

d: The gap between the plates

The capacitance changes directly proportional to the change in dielectric. This is due to the fact that water has a high dielectric constant. Air has a much lower one. This difference forms the basis of capacitive sensing.

Principle of a Capacitive Water Level Sensor

The sensor forms a capacitor. One electrode is the sensing element, while the other may be a reference electrode or ground.

The space between them includes the container wall and liquid. When the container is empty, air dominates the dielectric. So, the capacitance is low.

As water rises, air is replaced by water. The effective dielectric constant increases, and capacitance rises accordingly. The sensor electronics measure this change.

The measured value is converted into a signal. This signal represents the water level. The relationship is continuous. This allows for level measurement rather than simple detection.

Sensor Construction and Design

Capacitive water level sensors use simple structures. The sensing electrode may be a metal strip or foil. It can be mounted externally. In non-contact designs, the electrode sits outside the tank wall.

The tank wall acts as part of the dielectric. Plastic or glass containers work well. Metal containers require insulation. Some sensors use coaxial designs. Others use parallel plates.

The electronics are usually integrated. They include an oscillator or capacitance-to-digital converter.

Signal conditioning circuits process the raw measurement. Temperature compensation may also be included.

Types of Capacitive Water Level Sensors

Capacitive sensors can be classified by design. Contact and non-contact types are common. Contact capacitive sensors place electrodes inside the liquid. They provide high sensitivity.

However, they may be affected by contamination. Corrosion is also a concern. Non-contact capacitive sensors mount externally. They never touch the water. This improves durability and hygiene.

These sensors are common in drinking water systems. Sensors can also be point-level or continuous-level.

Point-level sensors detect specific heights, while continuous sensors provide full-level measurement.

Signal Processing and Output

The capacitance change is very small. Hence, accurate electronics are required. Many sensors use oscillators since capacitance affects oscillation frequency.

This frequency shift is measured. Other designs use charge-discharge timing. The time constant changes with capacitance.

Digital converters process the signal. A simple microcontroller may be used. The final output, most of the time, is analog.

Common outputs include 0–10 V or 4–20 mA. Digital outputs are also available, such as I²C, UART, or switching signals.

Calibration of Capacitive Water Level Sensors

Calibration ensures accurate measurement. It aligns sensor output with the actual water level.

Calibration may be factory-set, or it may also be field-adjustable. Typically, empty and full levels are recorded. Intermediate points may be added.

Software-based calibration is common. Some sensors support auto-calibration. Calibration compensates for tank material and accounts for wall thickness. Temperature effects can also be corrected.

Advantages of Capacitive Water Level Sensors

Capacitive sensors have no moving parts. This improves reliability because mechanical wear is eliminated. They support continuous measurement. Accuracy is generally good. Sensitivity can be adjusted.

Non-contact designs improve hygiene, and installation is simple. External mounting avoids tank modification. Maintenance requirements are low. Power consumption is also minimal.

Limitations and Challenges

Capacitive sensors detect variations in dielectric constant. Water composition affects performance, such as conductivity and impurities. Temperature variations influence the dielectric constant, so compensation may be required.

In addition, the tank material also affects the measurement. Thick or metallic walls can cause errors.

Also, foam and condensation may introduce noise. Hence, careful design is necessary. Proper calibration is critical.

Applications of Capacitive Water Level Sensors

Capacitive water level sensors are widely used. Water tanks are a common application. They are used in residential and commercial systems. In industrial processes, they monitor liquid levels. Examples include chemical tanks and cooling systems.

They are also used in HVAC equipment as well as agricultural irrigation systems. Consumer appliances also rely on them. For instance, include water dispensers and coffee machines.

Shortly,

- Industrial Automation: Precise control of liquids in pharmaceutical reactors. Also, in food processing, to ensure batch consistency.

- Smart Home Appliances: Integrated into coffee makers and dishwashers. Also, in floor scrubbers, to provide compact, leak-resistant level sensing.

- Environmental Monitoring: Early effect of a flood can be predicted if rivers and reservoirs are continuously monitored. Also, to aid sustainable water resource management.

- Agriculture: Applied in smart irrigation systems to help optimize water usage by relying on real-time water storage data.

Comparison with Other Level Measurement Methods

Float switches are simple but mechanical. This means they wear out over time, and accuracy is limited. Ultrasonic sensors are non-contact since they depend on sound waves. Foam and vapor can interfere.

Pressure sensors measure hydrostatic pressure. But they require contact. Density changes affect accuracy.

Capacitive sensors offer a balance. They are compact and reliable. So, they suit many applications.

Installation Considerations

Proper installation improves accuracy. Sensor placement matters. Such that external sensors must align with the water level range.

Tank material must be evaluated. For instance, plastic walls are ideal. Metal tanks need insulation layers.

Also, environmental factors should be considered. Moisture and temperature matter. In addition, electrical noise should be minimized.

Maintenance and Reliability

One advantage here is that maintenance requirements are minimal. Non-contact sensors require almost none. Periodic calibration may be needed. Electronics should be protected.

Enclosures must suit the environment. Long-term stability is generally good. With correct design, the lifespan is long. Reliability is high in static applications.

Future Developments

Capacitive sensing continues to evolve. Integration with IoT platforms is increasing. Smart sensors provide diagnostics. Improved algorithms enhance accuracy. Adaptive calibration is becoming common.

Multi-level detection is also advancing. Energy-efficient designs are in focus. Wireless connectivity is growing. Capacitive sensors remain relevant.

Conclusion

This article addressed capacitive water level sensors and their operation. The basic principle of capacitance was explained.

Sensor construction and signal processing were described. Types and applications were reviewed.

Advantages and limitations were discussed clearly. Capacitive water level sensors provide reliable measurement. They operate without moving parts. Non-contact designs improve durability and hygiene.

While calibration and material considerations are important, the benefits are significant. As industries adopt smarter systems, capacitive water level sensors continue to play an important role in accurate and efficient level measurement.

Frequently Asked Questions

What is a capacitive water level sensor?

It is a sensor that detects water level by measuring changes in capacitance caused by liquid between electrodes.

How does a capacitive water level sensor work?

Two electrodes form a capacitor. As water replaces air between them, the dielectric changes, increasing capacitance, which the electronics convert to a level signal.

Can these sensors be used without touching the liquid?

Yes. Some designs detect the level through the container wall, enabling non-contact sensing.

What kinds of outputs do they provide?

Outputs vary and can include analog signals like 4–20 mA or digital communications, depending on the model.

Are capacitive sensors reliable in harsh environments?

They are solid-state with no moving parts and can be sealed for durability, but calibration may be needed for variable liquids.