Calibration ensures precision in measuring tools. This process requires a specific device. That device is known as a calibrator.

It serves as a standard reference. Every industry relies on accurate data. Calibrators provide that essential certainty.

A calibrator is a high-precision instrument. It generates or measures physical values. These values include voltage and pressure. It can also simulate temperature signals. Technicians use it to verify tools.

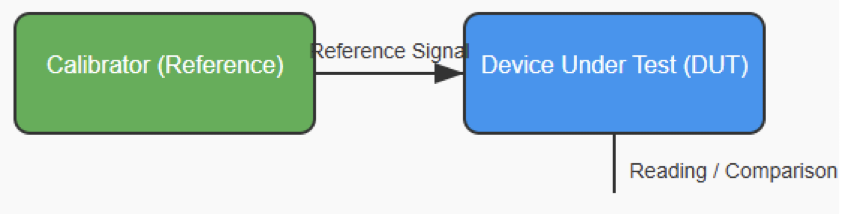

They compare a device under test. The calibrator provides the known value. This identifies errors in the tool.

Adjustments are made to ensure accuracy. Plus, regular calibration prevents costly operational errors.

It maintains safety in critical systems. Global standards define these calibration procedures. This article studies the role, types, and applications of calibrators.

What is a Calibrator?

A calibrator acts as a master. It holds a very high accuracy. It tests other measuring instruments.

Most tools drift over time. Environmental factors cause these small shifts. A calibrator detects these tiny changes. It provides a stable reference point.

You can find them in labs. You also see them in factories. They come in many different forms.

Some are handheld for fieldwork. Others sit on laboratory benches. Every calibrator must be calibrated itself.

This creates a chain of traceability. This chain leads to national standards. The following figure shows a diagram showing the comparison between a Calibrator (Reference) and a Device Under Test (DUT)

How Calibrators Work

The process begins with a signal. The calibrator generates a known output. For example, it produces ten volts.

The technician connects the target tool. The tool reads the generated signal. If the tool shows ten volts, it is accurate.

If it shows nine, it fails. The technician then adjusts the tool. This brings it back to specification. Some calibrators work by measuring instead.

They receive a signal from sensors. The calibrator displays the true value. It acts as the ultimate judge.

Precision components inside make this possible. High-quality resistors and chips are used.

Types of Calibrators

There are several types of calibrators. Each serves a specific physical property.

Electrical Calibrators

These handle voltage and current signals. They often test multimeters and scopes. They can simulate complex electrical waveforms. In electronics manufacturing, one of the most important features is precision.

Pressure Calibrators

These tools manage gas or liquid. They test gauges and pressure sensors. They often include a manual pump. Technicians apply specific pressure levels manually. Digital sensors record the exact force.

The upcoming figure illustrates a schematic of a pressure calibrator connected to a Bourdon tube gauge.

Temperature Calibrators

Temperature is critical in many processes. These devices simulate thermocouples or RTDs. Some use a “dry well” design.

A dry well heats a metal block. The sensor is placed inside it. The calibrator controls the block’s heat.

Multifunction Calibrators

Some units do many tasks at once. They handle volts, ohms, and pressure. These are popular for field technicians. One tool replaces several heavy boxes. They save time during site inspections.

Importance of Calibrators

Calibrators maintain the integrity and performance of measurement systems. The very important benefits are briefly explained below:

Accuracy and Precision

Without thinking that much, ensure instruments provide correct readings.

Safety

Helps avoid dangerous mistakes in essential operations

Compliance

Helps meet standards like IEC, ANSI, or ISO.

Cost Efficiency

Avoids losses due to faulty measurements or defective products.

Process Optimization

Ensures instruments in automation provide reliable feedback for control systems.

For example, in industrial automation, a flow transmitter’s incorrect reading can cause underfilling or overfilling. Calibrators ensure these devices operate within acceptable limits.

Types of Calibration Techniques

Calibration techniques vary by instrument and required accuracy:

Comparison Method

Compare the instrument reading directly with a standard.

Substitution Method

Replace the instrument under test with a standard to check accuracy.

Null Method

Adjust the instrument until the difference is zero.

Traceability

Traceability links measurements to NIST standards. Every calibrator has a pedigree. This history proves its inherent accuracy. Without traceability, calibration is just guesswork. It ensures global measurement consistency.

A meter in Japan matches one in London. This allows for international trade stability. Hence, as mentioned above, calibrators must be accurate.

This is ensured by traceable calibration. Calibration standards verify and adjust calibrators periodically.

- Traceability: Measurements link to national or international standards.

- Reference Instruments: Highly precise instruments validate the calibrator.

- Certification: Provides documented proof of accuracy.

Without traceable standards, calibration loses reliability. Instrument readings may drift without detection.

Applications of Calibrators

Industries rely on calibrators for precision:

- Industrial Automation: They verify flow and pressure sensors. This ensures consistent manufacturing quality control.

- Laboratories: They calibrate pH and temperature tools. Scientists need these for reliable experimental results.

- Aerospace and Defense: Aircraft and spacecraft require absolute accuracy. Calibrators keep navigation systems working safely.

- Energy Sector: Power plants monitor grid stability constantly. Accurate sensors prevent dangerous electrical failures.

- Healthcare: Medical monitors must read vital signs correctly. Calibrators ensure infusion pumps deliver medicine safely.

Drifting of Tools

Electronic components age over time. Heat causes parts to expand slightly. Humidity can affect sensitive circuit boards. Rough handling also causes physical shifts. Even gravity can impact some scales.

These factors lead to “measurement drift.” The tool slowly loses its accuracy. Regular calibration cycles catch this drift. It ensures the tool stays reliable.

How to Choose a Useful Calibrator

Determine your required level of accuracy. The calibrator must be more precise, and usually, a four-to-one ratio is used. This means it is four times better. Consider the environment of your work.

Labs need high-precision benchtop units. Fieldwork requires rugged, portable designs. Look for easy-to-read digital displays, and consider that the battery life is also very important.

Maintaining Calibrators

No doubt that the reliability of calibrators must be maintained. To achieve this, taking proper care is not an option.

Performing regular calibration helps ensure their accuracy. This is achieved by calibrating the devices on a scheduled basis.

As we know, environmental conditions affect everything in our daily lives. In this case, the performance calibrators are not an exception.

This is to say, calibrators should not be exposed to extreme weather conditions. For instance, high temperatures.

High humidity may also reduce their accuracy. Strong vibrations may compromise their precision.

The further the protection will be obtained if the proper storage is used. Remember to keep all calibrators within the cases.

This must be done whenever the calibrators are not in use. High risk of damage is reduced, plus it ensures their longevity.

Routine checks are equally important. Battery status, display functionality, and connections should be verified regularly.

This ensures the device operates correctly. Do not neglect these care practices because it can lead to inaccurate readings.

Such errors can negatively impact production and compromise safety. They can also reduce the overall reliability of measurement systems.

Key Takeaways: What is a Calibrator?

This article reviewed the importance and function of calibrators. Precision is the foundation of technology.

We cannot build without accurate measurements. The calibrator makes this precision possible. It acts as the guardian of truth.

From medicine to space, it matters. It eliminates doubt in scientific data. Every technician needs a reliable calibrator.

It ensures that “one inch” is “one inch.” Without them, modern industry would fail. They represent the gold standard of quality.

Investing in calibration is investing in safety. It is the heartbeat of modern metrology. Accurate tools lead to better products.

Always trust a certified calibration source. Protect your data with regular checks. This ensures a future of excellence.

FAQ: What is a Calibrator?

What is a calibrator?

A calibrator is a device that provides a known reference to check other instruments.

Why use a calibrator?

It ensures measurement instruments are accurate and reliable.

What is calibration?

Calibration compares an instrument’s reading to a known standard.

What is a Device Under Test (DUT)?

It’s the instrument being checked against the calibrator.

Should a calibrator be more accurate than the DUT?

Yes, usually at least four times more accurate.

What values can calibrators generate?

Voltage, current, pressure, temperature, or other signals.

How is calibration documented?

Results are recorded in a calibration certificate.

What if errors are found?

The instrument is adjusted to match the reference.