A Safety Integrity Level (SIL) is a measure that defines how reliable and effective a safety-critical system is. It helps to evaluate how well a system can prevent or control hazards.

SIL applies to electrical, electronic, and programmable systems that perform essential safety functions.

The concept is based on functionalsafety, which ensures systems behave correctly even when failures occur.

Its goal is to keep risks within acceptable limits. Defined by the IEC 61508 standard, SIL has fourlevels, from SIL 1 (basic integrity) to SIL 4 (highest reliability).

This article explores the meaning, determination, and application of SIL. It explains how SIL supports functional safety, how levels are assigned, and why certification is important for safe and reliable industrial systems.

What is Functional Safety?

Functional safety is a key part of overall safety engineering. It focuses on preventing hazards that may result from failures in control or protection systems.

Unlike mechanical safety, which relies on barriers or physical design, functional safety ensures that electronic systems detect faults.

They then respond to and correct these faults automatically to maintain safe operation.

It applies to electrical and electronic control systems, including PLCs, sensors, and actuators.

Functional safety ensures that if a failure occurs, such as a sensor or logic malfunction, the system reacts promptly.

Its response is designed to avoid or reduce danger. The main goal is to lower risk to a tolerable level.

This is achieved through safety functions that are designed, tested, and maintained according to recognized standards.

These functions, known as Safety Instrumented Functions (SIFs), are essential for implementing functional safety in modern industrial systems.

Safety Instrumented Functions (SIFs)

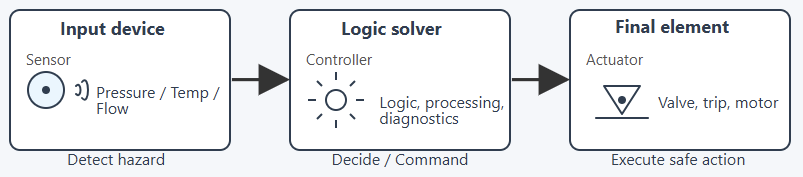

A Safety Instrumented Function (SIF) is a specific safety task carried out by a Safety Instrumented System (SIS). Each SIF is composed of three main elements:

Input device (sensor)

Continuously monitors a process variable, such as pressure, temperature, or flow rate.

Logic solver (controller)

Interprets signals from the sensors and determines whether a hazardous condition exists.

Final element (actuator)

Performs the corrective action to bring the system into a safe state, such as shutting a valve or stopping a motor.

These elements work together to detect hazardous events and respond before they escalate. For example, in a chemical plant, a pressure sensor may detect an abnormal rise in pressure.

The logic solver processes this signal and commands a valve (the final element) to open, releasing pressure safely.

SIFs are fundamental building blocks of functional safety. They transform potential hazards into manageable events through automation and control logic.

The next figure indicates a simple diagram of a Safety Instrumented Function (SIF), showing the flow from an input device (sensor), logic solver (controller), and final element (actuator).

The Meaning of SIL Levels

Each Safety Integrity Level corresponds to a defined probability of failure. The higher the SIL, the lower the likelihood that a safety function will fail when demanded.

- SIL 1: Used in applications with relatively low risk. It provides basic protection but requires minimal redundancy and diagnostic coverage.

- SIL 2: Applied where the risk is moderate, demanding stricter design, testing, and verification.

- SIL 3: Reserved for high-risk environments such as oil and gas, chemical, or nuclear plants, where failure could have severe consequences.

- SIL 4: The highest integrity level, used in extremely critical processes such as aerospace systems, railway signaling, or nuclear reactor control.

Each level represents an order of magnitude decrease in the probability of dangerous failure. Therefore, achieving a higher SIL requires more rigorous design, documentation, testing, and maintenance practices.

How SIL is Determined

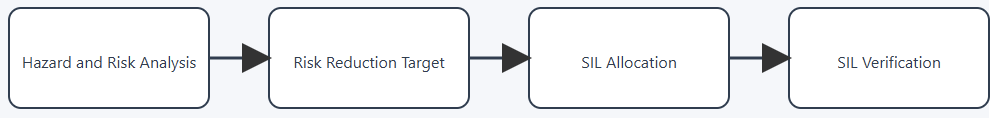

Determining the appropriate SIL for a safety function is not arbitrary, it follows a structured risk analysis process. The typical steps include:

- Hazard and Risk Analysis (H&RA): Identify all potential hazards and estimate the likelihood and consequence of each event.

- Risk Reduction Target: Compare the initial (unmitigated) risk with the tolerable risk to determine how much risk reduction is required.

- SIL Allocation: Assign a SIL level that provides the necessary risk reduction, often through methods like Layer of Protection Analysis (LOPA).

- SIL Verification: Ensure through calculation, testing, and analysis that the system design can actually meet the target SIL.

The following figure illustrates flowchart showing SIL determination: from Hazard and Risk Analysis, Risk Reduction Target. SIL Allocation, to SIL Verification.)

This process ensures that the safety measures are proportionate to the level of risk, balancing safety performance, cost, and practicality.

Achieving SIL Compliance

To achieveaspecific SIL, a system must meet strict criteria defined by IEC 61508. Compliance involves two key aspects:

Systematic Integrity

Addresses failures caused by design mistakes, programming errors, or incorrect procedures. This is managed through qualityassurance, designreviews, and functionaltesting.

Hardware Safety Integrity

Deals with random hardware failures using statistical methods such as Probability of Failure on Demand (PFD) or Probability of Dangerous Failure per Hour (PFH).

Ultimately, the lowest achieved integrity level among all components determines the system’s overall SIL.

Therefore, each part hardware, software, and process must consistently meet its assigned reliability targets.

Common Pitfalls and Misconceptions

Despite its structured approach, SIL is often misunderstood or misapplied. Some common misconceptions include:

- SIL applies to a function, not a device: It is incorrect to label a single sensor or controller as “SIL 3 certified” without considering the complete safety function it performs.

- Higher SIL isn’t always better: Over specifying SIL can unnecessarily increase cost and complexity without proportionate safety benefits.

- SIL applies to electronic systems only: Purely mechanical or procedural safety systems are not evaluated using SIL.

Understanding these distinctions helps avoid costly design errors and ensures that safety measures remain both effective and efficient.

The Importance of SIL Certification

SIL certification provides independent verification that a product or system complies with IEC 61508 requirements.

Certification bodies evaluate designprocesses, testingmethods, and documentation.

They also review lifecycle management to ensure that safety is integrated at every stage. Manufacturers often seek SIL certification to demonstrateproductreliability. End users may also require it contractually to ensure regulatorycompliance and operationalconfidence.

Certification not only validatestheproduct but also enhances market credibility. It helps build customertrust and shows a strong commitment to safety and quality.

Industry and Applications

SIL is applied across many industries where safety is critical:

- Process industries (oil, gas, and chemical): Used in emergency shutdown systems, fire and gas detection, and pressure relief systems.

- Railway systems: Applied to signaling, train control, and collision avoidance systems.

- Machinery safety: Governed by the IEC 62061 standard, ensuring safe operation of automated machinery.

- Automotive industry: Uses a parallel concept known as Automotive Safety Integrity Level (ASIL) under ISO 26262 to ensure vehicle functional safety.

Each industry tailors SIL application to its unique risks, but all share the same goal: minimizing the probability of dangerous failures.

Key takeaways: What does SIL Mean?

This article studied the concept, determination, and application of Safety Integrity Levels (SIL) within the context of functional safety. SIL provides a standardized and quantifiable measure of reliability for safety functions.

It helps engineers design systems that manage risk effectively. By applying SIL principles, industries can ensure that safety critical systems operate predictably, even under fault conditions.

Compliance with standards like IEC 61508 safeguards human life and assets. It also supports environmental protection and maintains operational continuity.

In modern industrial automation, understanding and using SIL correctly is a sign of responsible engineering. It ensures every safety function is justified, tested, and maintained to perform as intended.

So, SIL is not just a measure of integrity; it is a cornerstone of safe, reliable, and sustainable industrial design.

FAQ: What does SIL Mean?

What does SIL mean?

SIL stands for Safety Integrity Level. It is a discrete level (from 1 to 4) used to indicate how reliable a specific safetyinstrumented function (SIF) must be in reducing risk.

How many SIL levels are there and what do they signify?

There are four levels: SIL 1, SIL 2, SIL 3 and SIL 4. SIL 1 is the lowest integrity level (less strict requirements) and SIL 4 is the highest (most stringent requirements).

When is SIL applied?

SIL is applied to safetyinstrumented functions in systems that include electrical, electronic or programmable electronic components (E/E/PE). It is not applied to purely mechanical safety functions.

How is a SIL level determined?

A SIL level is determined through risk assessment, using methods such as hazard & risk analysis (H&RA), layer of protection analysis (LOPA) or risk graphs.

The process compares unmitigated risk to a tolerable risk and assigns a SIL that offers the required risk reduction.

Does a component (sensor, valve, controller) itself have a SIL rating?

No. A component can be “SIL capable” (i.e., suitable for use in a system meeting a particular SIL), but the SIL rating applies to the safety function as a whole, not to individual parts alone.

Why does achieving higher SIL cost more?

Higher SIL means stricter requirements for hardware reliability, diagnostic coverage, redundancy, systematic integrity (process and software quality) and verification throughout lifecycle. All of this adds complexity and cost.

What are the key metrics used in SIL evaluation?

Key metrics include Probability of Failure on Demand (PFD) or Probability of Dangerous Failure per Hour (PFH) for hardware safety integrity, as well as meeting systematic capability requirements in design, development and maintenance.

Is SIL certification needed?

Yes, often. Independent certification provides assurance that a system or product meets the safety‐integrity requirements of the relevant standard (e.g., IEC 61508) and can be used as part of a safety function at a given SIL level.