A PLC stands for Programmable Logic Controller, is a specialized industrial computer.

It is designed to operate machinery and control processes in harsh environments.

Factories, power plants, and production lines rely on PLCs to automate repetitive and complex tasks.

These devices were developed to replace large, cumbersome relay based systems. PLCs execute programmed instructions based on their inputs. They then control outputs like motors, valves, and other actuators.

This allows high reliability, flexible control, and simple reprogramming. From assembly lines to traffic lights, PLCs are essential. They collect data, execute logic, and interface with other systems.

The result is improved efficiency, safety, and precision in industrial operations worldwide.

This article explores the meaning, evolution, architecture, functions, and applications of PLCs, as well as their role in modern Industry 4.0 environments.

Brief History of PLCs

Before PLCs existed, industrial automation relied heavily on electromechanical relays.

Each manufacturing process required complex wiring. Whenever a process changed, engineers had to rewire large control panels.

This was expensive and time consuming. The automotive industry faced a particular challenge because production lines needed frequent retooling for new car models.

In 1968, General Motors requested a new type of controller. It had to be electronic, programmable, and adaptable. Engineer Dick Morley and his team responded by creating the Modicon 084.

The name “Modicon” came from “modular digital controller.” This device replaced hardware based relay logic with software driven control. It marked the beginning of modern industrial automation.

Factories could now reprogram controllers without physically rewiring circuits. This innovation laid the foundation for the automated factories we see today.

The Basic Architecture of a PLC

A PLC is essentially a specialized computer built for industrial environments. It can withstand high temperatures, dust, vibration, and electrical noise.

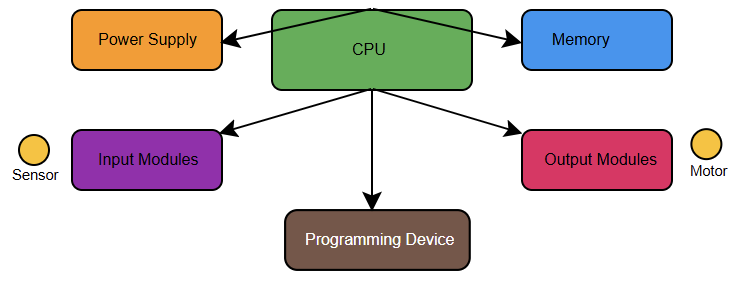

While companies like Siemens, Allen-Bradley, and Mitsubishi have proprietary designs, PLCs share a common architecture. The following figure illustrates a conceptual PLC System Architecture.

- CPU connected to power supply, memory, and I/O modules.

- I/O modules interface with sensors (inputs) and actuators (outputs).

- A programming device connects to the CPU to upload code.

The architecture is simple but robust. Each component plays a vital role in controlling industrial processes.

Core Components of a PLC

PLC core components are:

Central Processing Unit (CPU)

The CPU is the brain of the PLC. It executes control programs, performs calculations, and manages data flow. Without the CPU, the PLC cannot function.

Memory

Memory stores the operating system and user programs. It also keeps input data, timers, and counters.

Modern PLCs use flash memory or battery-backed RAM to prevent data loss during power failures.

Power Supply

This unit converts standard AC voltage to the DC voltage needed by the PLC. It is rugged and reliable, built to survive industrial conditions.

Input Modules

Receive signals from devices such as pushbuttons, sensors, and limit switches. Digital inputs detect on/off states. Analog inputs measure ranges, like temperature or pressure.

Output Modules

Send commands to motors, solenoids, valves, and lamps.

Programming Device

Engineers use PCs or specialized handheld devices to write PLC programs. These devices also allow debugging and simulation.

Communications Interface

PLCs can communicate via Ethernet, USB, RS-485, and industrial protocols like Modbus or EtherNet/IP. They connect with other PLCs, SCADA systems, and Human-Machine Interfaces (HMIs).

The PLC Scan Cycle: Predictable and Reliable

PLCs operate in a continuous loop called the “scan cycle.” This ensures consistent processing and output updates. The cycle usually has four steps:

- Internal Checks: The PLC performs self-diagnostics.

- Read Inputs: The CPU reads all connected inputs and stores their values.

- Execute Logic: The CPU runs the control program line by line. Inputs determine the outputs.

- Update Outputs: Outputs are adjusted according to the program’s logic.

This cycle completes in milliseconds. Fast and predictable cycles are essential for real-time control. They prevent machines from malfunctioning due to timing errors.

PLC Programming Languages

Early PLCs were programmed to resemble relay logic. This made it easier for electricians to transition to electronic controllers. Today, the IEC 61131-3 standard defines several PLC programming languages:

Ladder Logic (LD)

The most common language. It looks like relay diagrams with vertical rails and horizontal rungs. Easy to read and debug.

Function Block Diagram (FBD)

Uses blocks to represent logic functions such as timers and counters. Blocks are connected by lines showing data flow.

Structured Text (ST)

Text-based, similar to high-level languages like Pascal. Used for complex calculations or algorithms.

Sequential Function Chart (SFC)

Graphical language for processes with multiple sequential steps. Resembles a flowchart.

These languages make PLC programming flexible, allowing adaptation to different industrial needs.

PLC Applications

PLCs are extremely versatile. They are used in simple repetitive tasks and in highly complex, coordinated operations.

Manufacturing and Assembly Lines

PLCs sequence operations, control robots, and ensure proper packaging.

Food and Beverage Industry

They control conveyor speeds, regulate temperatures, and manage automated cleaning processes.

Energy and Utilities

PLCs control turbines, pumps, and environmental monitoring in power plants and water treatment facilities.

Building Automation

HVAC systems, lighting, and security access are often PLC-controlled.

Transportation

Traffic lights, airport baggage handling, and amusement park rides rely on PLCs.

Their adaptability makes PLCs a backbone of industrial automation.

The Future of PLCs in Industry 4.0

PLCs continue to evolve with modern technology.

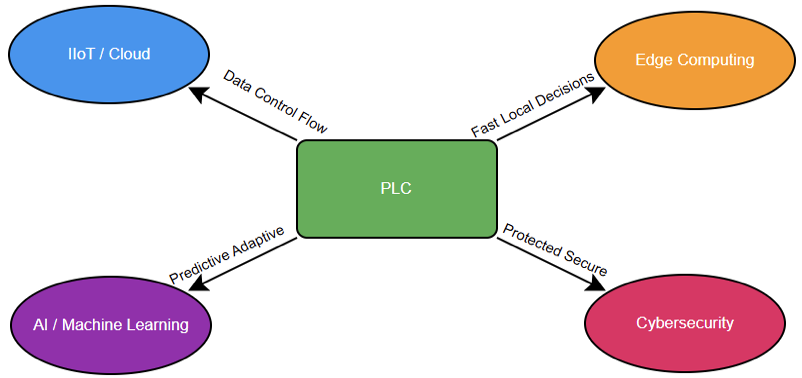

Industrial Internet of Things (IIoT)

PLCs now connect to cloud platforms for massive data collection. Predictive maintenance and process optimization are possible.

Edge Computing

PLCs process data locally, enabling fast decision-making for real-time control.

AI and Machine Learning

Integration with AI allows PLCs to learn from production data and optimize processes automatically.

Cybersecurity

Modern PLCs include advanced security features to protect industrial networks.

These innovations ensure PLCs remain relevant in increasingly connected and intelligent factories. The next figure shows the Future of PLCs in Industry 4.0.

Difference PLC and PC

PLCs and PCs differ significantly in their design and purpose. PLCs are built to operate in harsh industrial environments, while PCs are intended for office or home use.

They use different operating systems: PLCs run specialized real-time OS optimized for control tasks, whereas PCs rely on general purpose systems like Windows.

In execution, PLCs follow a predictable scan cycle, ensuring consistent operation, while PCs operate in an event-driven manner.

Reliability is another key difference: PLCs are extremely robust and designed for continuous long term operation, whereas PCs are more prone to crashes and require regular maintenance.

Programming also varies: PLCs use industrial languages such as Ladder Logic, while PCs typically employ general purpose languages like C++ or Python.

Finally, the purpose of each device is distinct: PLCs focus on industrial automation and real-time control, whereas PCs handle a wide range of general computing tasks.

Industrial PCs (IPCs) are hybrids. They combine PLC durability with PC versatility. Yet, PLCs remain preferred for critical real-time industrial control.

Key Takeaways: What Does PLC Stand For?

This article studied the meaning, history, architecture, programming, applications, and future of PLCs.

It highlights their enduring importance in modern industrial technology and their role as the backbone of automated systems.

PLCs have transformed the way industries operate. From replacing bulky electromechanical relays to supporting the complex demands of Industry 4.0, PLCs have consistently proven their value.

They are rugged, reliable, and versatile, capable of performing real-time control in even the harshest industrial environments.

PLCs ensure that manufacturing processes run efficiently, safely, and with high precision.

Their predictable scan cycle, flexible programming options, and compatibility with modern technologies like IIoT, edge computing, and AI make them indispensable for today’s smart factories.

Moreover, PLCs allow engineers to monitor, analyze, and optimize operations, enabling predictive maintenance and improved productivity.

As factories and industrial systems become increasingly connected and intelligent, the PLC continues to play a central role in automation.

Its ability to integrate with modern technologies while maintaining real-time control ensures it remains a cornerstone of industrial innovation.

In the years ahead, PLCs will continue evolving, driving smarter, safer, and more efficient automation across industries worldwide.

FAQ: What Does PLC Stand For?

What does PLC stand for?

PLC stands for Programmable Logic Controller. It automates industrial processes.

What is the primary function of a PLC?

It reads inputs, runs a program, and controls outputs like motors or valves.

Where are PLCs commonly used?

In factories, water treatment, food processing, HVAC, and traffic systems.

How does a PLC operate?

It runs a scan cycle: read inputs → execute program → update outputs.

What programming languages are used for PLCs?

Ladder Logic, Function Block Diagram, Structured Text, Sequential Function Chart.

What are the key components of a PLC?

CPU, I/O modules, Power Supply, Memory, Programming Device.

How is a PLC different from a PC?

PLCs are rugged, real-time, industrial computers. PCs are general-purpose.

What advancements exist in modern PLCs?

IIoT, Edge Computing, AI, Machine Learning, Cybersecurity.

Can a PLC be used outside industry?

Yes, in building automation, rides, and home automation.

How can I learn more about PLCs?

Use tutorials, courses, and hands-on programming.