Limit switches are vital devices in industrial automation. They detect the position, presence, or movement of machine parts.

These devices convert mechanical action into electrical signals. Industries rely on them for control and safety.

They help prevent collisions and mechanical damage. Limit switches improve the reliability of automated systems.

They are simple, rugged, and highly dependable components. Modern factories still depend on these classic devices.

They operate under harsh environmental conditions reliably. They support precise motion control in many applications.

Different designs exist for different operational needs. Understanding types helps engineers select suitable devices.

This article reviews the main types of limit switches, their operation, and their industrial applications.

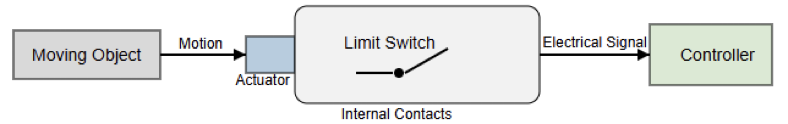

Basic Working Principle

A limit switch uses physical contact for actuation. An external object applies force to an actuator.

Internal contacts change state after actuation. This change sends an electrical control signal. The signal starts, stops, or reverses motion.

Springs return actuators after force removal. Contacts may be normally open or closed. Simple construction ensures long operational life.

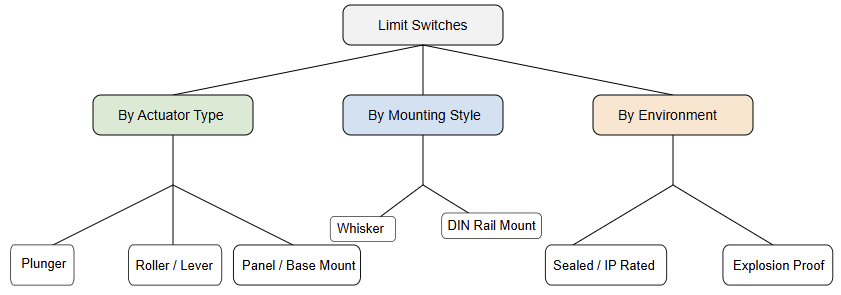

Classification of Limit Switches

Limit switches are classified by actuator design. They are also classified by mounting style. Contact configuration offers another classification method.

Environmental ratings further differentiate switch types. Application requirements guide the final classification choice.

Plunger-Type Limit Switches

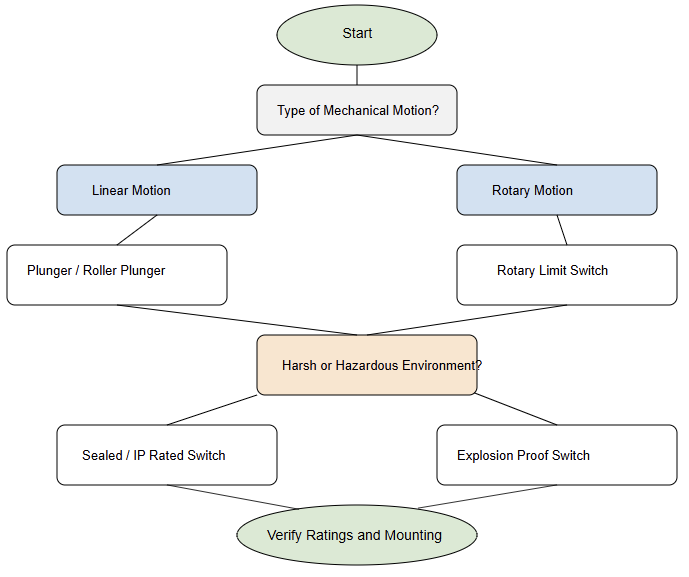

Plunger limit switches use linear actuator motion. A moving object presses the plunger directly.

Plunger movement triggers internal contact change. These switches offer high positional accuracy.

They suit applications with straight-line motion. Plungers withstand repeated mechanical impacts well.

Overtravel protection improves plunger switch durability. They require precise alignment during installation.

Roller Plunger Limit Switches

Roller plunger switches reduce actuator friction significantly. A roller replaces the standard plunger tip. The roller follows moving parts smoothly. This design minimizes wear during operation.

They handle side loads better than plungers. Roller plungers extend operational life considerably. They are common in conveyor systems.

Lever Arm Limit Switches

Lever arm switches use pivoted mechanical arms. The arm moves when contacted by objects. Movement rotates internal cam mechanisms.

This rotation actuates the electrical contacts inside. Lever arms handle angular or lateral motion.

They are flexible for varied actuation directions. Adjustable levers allow sensitivity modification. They suit packaging and material handling machines.

Roller Lever Limit Switches

Roller lever switches include rollers on levers. The roller reduces friction during actuation. They allow smooth engagement with moving surfaces. Rollers prevent damage to contacting objects.

These switches handle continuous motion effectively. They are common in high-speed machinery. Roller levers reduce noise during operation.

Whisker-Type Limit Switches

Whisker switches use flexible wire actuators. Thin metal whiskers detect light contact. They require minimal actuation force.

Whiskers bend easily without mechanical damage. They suit delicate or lightweight components. Sensitivity makes them ideal for detection tasks. They are less suitable for harsh impacts.

Rotary Limit Switches

Rotary limit switches respond to angular motion. A rotating shaft drives internal cams. Cams actuate contacts at set angles. These switches monitor rotational position accurately.

They control cranes, hoists, and elevators. Multiple contacts enable multi-position control. They support complex sequencing operations.

Heavy-Duty Limit Switches

Heavy-duty limit switches handle extreme conditions. They feature robust housings and strong actuators. These switches resist shock and vibration. They operate reliably in dirty environments.

Metal enclosures provide mechanical protection. They are used in the steel and mining industries. Long service life reduces maintenance requirements.

Miniature Limit Switches

Miniature limit switches fit compact installations. They offer similar functions in smaller sizes. These switches suit space-constrained equipment. Despite size, reliability remains high.

They operate with lower actuation forces. Miniature designs support precise sensing tasks. They are common in electronics manufacturing.

Sealed Limit Switches

Sealed limit switches prevent contaminant entry. They use gaskets and tight enclosures. One of the very important tasks of sealing is protection against moisture and dust. They perform well in washdown environments.

Ingress protection ratings define sealing effectiveness. Sealed switches extend service life significantly. They suit the food and pharmaceutical industries.

Explosion-Proof Limit Switches

To operate in hazardous areas, a special kind of limit switch called an explosion-proof switches are used.

They contain sparks within robust housings. These switches prevent ignition of flammable gases. They meet strict safety certification standards.

Heavy casings withstand internal explosions safely. They are critical in oil and gas plants. Proper installation ensures safe operation.

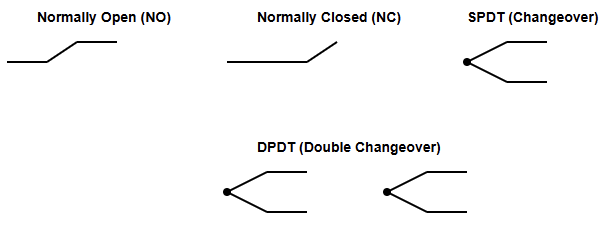

Contact Configurations

Limit switches offer various contact arrangements. Common types include SPDT and DPDT. Normally open contacts close upon actuation. Normally closed contacts open during actuation.

Dual contacts provide redundancy and flexibility. Contact selection affects control logic design.

Electrical Ratings

Electrical ratings define voltage and current limits. Exceeding ratings reduces switch lifespan significantly.

AC and DC ratings differ considerably. Proper rating selection ensures safe operation. Inductive loads require special consideration. Engineers must verify ratings before installation.

Mounting Styles

Limit switches support various mounting options. Panel mounting allows easy accessibility.

Base mounting offers rigid mechanical support. DIN rail mounting simplifies control cabinet installation.

Mounting choice affects alignment and accuracy. Proper mounting reduces mechanical stress.

Applications of Limit Switches

Limit switches appear across many industries. They control conveyor belt positions. They ensure safe machine travel limits.

Elevators rely on limit switches for safety. Packaging machines use them for positioning. Robotics systems depend on precise limit detection. They support automation and process reliability.

Advantages of Limit Switches

Limit switches provide simple, reliable operation. They require minimal electronic complexity.

Mechanical actuation ensures clear signal states. They tolerate electrical noise well. Maintenance requirements remain relatively low.

They operate without external power sources. Cost-effectiveness benefits many applications.

Limitations of Limit Switches

Mechanical contact causes eventual wear. High-speed systems may exceed response limits. Physical alignment is critical for reliability.

Repeated impacts reduce mechanical lifespan. Non-contact sensors sometimes offer better solutions. Application evaluation helps mitigate limitations.

Selection Considerations

Proper selection depends on application conditions. Engineers must evaluate the mechanical movement type. Environmental factors influence enclosure choice.

Electrical load determines contact configuration. Mounting space limits switch dimensions. Safety requirements guide certification needs.

Maintenance and Testing

Regular inspection ensures reliable limit switch operation. Check actuator alignment and physical damage.

Test contact continuity during maintenance routines. Replace worn components promptly when detected.

Clean actuators to prevent sticking issues. Preventive maintenance extends operational lifespan.

Future Trends

Limit switches remain relevant despite sensor advances. Hybrid designs integrate mechanical and electronic sensing.

Smart switches provide diagnostic feedback signals. Industry still values mechanical reliability.

Cost-sensitive applications favor limit switches. They coexist with proximity sensor technologies.

Key takeaways: Types of Limit Switches

This article depicted the structure, operation, and classification of limit switches used in industry.

Limit switches are fundamental industrial control devices. They provide reliable mechanical position detection.

Many designs address diverse application requirements. Understanding types improves engineering decision-making.

Proper selection enhances safety and system performance. Despite new technologies, demand remains strong. Limit switches continue to support industrial automation worldwide.

FAQ: Types of Limit Switches

What is a limit switch?

A limit switch is a device that detects position or motion and sends an electrical signal.

Where are limit switches used?

They are used in industrial machines for position control and safety.

What are the main types of actuator?

Plunger, roller plunger, lever arm, roller lever, and whisker.

What is a plunger limit switch?

It uses a straight sliding stem to detect linear motion.

What is a roller plunger switch?

A plunger with a roller wheel to reduce friction.

What is a lever arm switch?

A pivot arm that moves when contacted by a machine part.