Temperature measurement plays a critical role in engineering systems. Process stability and efficiency can be ensured by a correct temperature.

So, this provides safety. Many industrial processes depend on reliable temperature sensing devices.

Thermocouples are among the most widely used temperature sensors. They are valued for wide temperature capability, durability, and simplicity. Thermocouples operate based on a fundamental thermoelectric phenomenon.

This phenomenon converts temperature differences into measurable electrical voltage. No external power source is required for thermocouple operation. They function reliably under harsh industrial environments.

Corrosive conditions, vibrations, and high temperatures do not easily damage them. Technicians and engineers need to understand the thermocouple working principle. Correct knowledge ensures accurate measurements and proper sensor selection.

This article explains thermocouple operation, construction, characteristics, and their applications in industry.

Basic Concept of Thermocouples

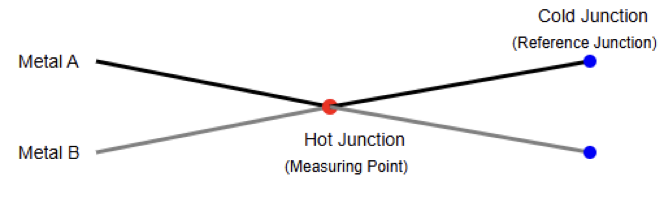

A thermocouple uses two unlike metallic wires. These wires are joined together electrically at one end.

The joint point is called the measuring junction. The free ends connect to a measuring instrument. When a temperature difference exists, a small electrical voltage appears.

This voltage depends on the metals used. Thermocouples measure temperature indirectly using voltage generation.

The measured voltage represents the temperature difference. Proper interpretation converts voltage into temperature values.

Seebeck Effect and Its Role

Thermocouples operate based on the Seebeck effect. This outcome explains a relationship between heat and magnetism. German physicist Thomas Seebeck discovered this thermoelectric phenomenon.

It occurs when dissimilar conductors form a closed circuit. A temperature gradient causes charge carriers to move. This movement generates an electromotive force within conductors.

The resulting voltage is proportional to the temperature difference. Each metal pair has a unique Seebeck coefficient. This coefficient determines thermocouple sensitivity and output characteristics.

Hot Junction and Cold Junction Concept

Thermocouples contain two essential temperature junctions. The hot junction senses the process temperature directly.

It is placed inside the measurement environment. The cold junction serves as the reference junction. It remains at a known reference temperature.

Voltage develops due to the temperature difference between junctions. Accurate reference temperature ensures reliable measurements. Modern instruments compensate for reference temperature electronically.

Cold Junction Compensation

Cold junction compensation is required for accurate thermocouple readings. It corrects errors caused by reference temperature variations.

Earlier systems used ice baths as reference junctions. Modern systems use electronic temperature sensors instead.

Compensation circuits adjust the measured thermocouple voltage. This adjustment ensures correct temperature calculation.

Without compensation, significant measurement errors occur. Digital instruments perform compensation automatically.

Thermocouple Voltage Generation Characteristics

In general, a very small number of electrical voltages is generated by thermocouples. Typical outputs are in microvolt ranges.

Voltage increases as the temperature difference increases. Each thermocouple type produces characteristic voltage curves. These curves are nonlinear across temperature ranges.

Signal conditioning improves measurement accuracy significantly. Amplifiers increase voltage to measurable levels. Filtering reduces electrical noise interference.

Common Thermocouple Types

Many standardized thermocouple types are widely used worldwide. Each type uses specific metal combinations.

Type K uses nickel-chromium and nickel-aluminum materials. Type J uses iron and constantan metals.

Type T uses copper and constantan conductors. Types R and S use platinum alloys. Each type supports specific temperature ranges. Material choice affects accuracy and longevity.

Materials and Construction

Thermocouple materials are selected for long-term stability and must withstand high temperatures and oxidation effects.

Insulation prevents electrical short circuits between conductors. Common insulation materials include fiberglass and ceramic compounds.

Protective sheaths improve mechanical strength significantly. Metal sheaths resist corrosion and vibration effectively.

Construction affects response time and durability. Proper selection ensures long-term reliable operation.

Measurement Circuit and Instrumentation

Thermocouples connect to specialized temperature-measuring instruments. These instruments convert voltage into temperature readings.

Analog meters display temperature using calibrated scales. Digital instruments use internal conversion algorithms.

Microcontrollers apply polynomial approximations for conversion. Signal conditioning improves accuracy and stability.

Electrical isolation protects sensitive measurement circuits. Proper grounding reduces electrical noise problems.

Accuracy and Sensitivity Considerations

The accuracy of a thermocouple depends on multiple influencing factors. Material purity strongly influences output stability.

Junction quality affects thermal response accuracy. Cold junction compensation accuracy is essential.

Long-term measurement reliability can be improved by performing calibration. It has been proven that thermocouples are less accurate than RTDs.

However, they tolerate extreme temperatures better. Sensitivity varies depending on thermocouple type.

Response Time Characteristics

Generally, relatively fast response times are offered by all thermocouples. Smaller junctions respond faster to temperature changes.

Sheathed probes respond more slowly due to thermal mass. Response time depends on construction and environment.

Bare junctions provide the fastest measurements. However, they offer minimal mechanical protection.

Engineers balance speed and durability requirements. Application determines optimal probe selection.

Advantages of Thermocouples

Thermocouples operate over extremely wide temperature ranges. They require no external power supply.

Their construction is simple and robust. They perform reliably in harsh environments. Thermocouples resist vibration and mechanical shock.

They are relatively inexpensive sensors. Maintenance requirements remain minimal. They suit high-temperature industrial applications.

Limitations of Thermocouples

Thermocouples produce very low output voltages. This makes them susceptible to electrical noise interference. Accuracy is lower compared to RTDs. The output voltage is nonlinear with temperature.

Cold junction compensation increases system complexity. Material aging causes long-term measurement drift.

Periodic calibration may be required. Signal conditioning increases overall system cost.

Industrial Applications

Many industries across the world use thermocouples in daily basis. They monitor furnace and kiln temperatures.

Power plants use them for turbine monitoring. Engines use thermocouples for exhaust measurements.

Steel manufacturing requires high-temperature thermocouples. Chemical processes rely on temperature feedback.

Food processing equipment uses thermocouple sensors. Aerospace systems also depend on thermocouples.

Comparison with Other Temperature Sensors

Thermocouples differ significantly from thermistors and RTDs. Thermistors provide high sensitivity at low temperatures.

RTDs offer higher accuracy and stability. Thermocouples are suitable in operation where much higher temperatures are involved.

They withstand harsher operating environments. Response time is generally faster. Sensor choice depends on application requirements. Cost and durability influence selection decisions.

Installation and Best Practices

Proper installation ensures accurate temperature measurement results. Avoid sharp bends near the junction.

Use correct extension and compensation cables. Also, ensure good thermal contact with surfaces.

One of the very unwanted disruptions in an electronic circuit is electromagnetic interference (EMI).

Hence, wires must be protected at all costs from this phenomenon. Also, avoid mixing different thermocouple materials.

Follow the manufacturer’s installation recommendations carefully. Regular checks enhance reliability over extended periods.

Calibration and Maintenance

Calibration verifies thermocouple measurement accuracy periodically. Reference temperature sources are used for calibration.

Periodic calibration compensates for material drift. High temperatures accelerate aging effects.

Maintenance includes checking the insulation condition regularly. Damaged probes should be replaced promptly. Clean junctions improve thermal contact. Documentation ensures traceability and compliance.

Key takeaways: Thermocouple Working Principle

This article reviewed the thermocouple working principle thoroughly. Thermocouples are essential temperature measurement devices.

They operate using the Seebeck thermoelectric effect. Two dissimilar metals generate voltage from temperature differences.

Their simple design enables widespread industrial use. They perform reliably in extreme temperature environments.

Despite limitations, their advantages remain significant. Proper selection ensures accurate and stable measurements.

Understanding their working principle improves engineering decisions. Thermocouples are, and will remain, vital in industrial instrumentation systems.

FAQ: Thermocouple Working Principle

What is a thermocouple?

A thermocouple is a temperature sensor made from two dissimilar metal wires joined at a junction.

How does a thermocouple work?

It generates a small voltage proportional to the temperature difference between two junctions.

What principle explains thermocouple operation?

Thermocouples operate based primarily on the Seebeck effect.

What is the Seebeck effect?

When two dissimilar metals form a junction and experience a temperature difference, a thermoelectric voltage (EMF) is produced.

Does a thermocouple measure absolute temperature?

Not directly, it measures the difference between the hot junction and a reference (cold) junction.

What is the “hot junction”?

The hot junction is the point where the two different metals are joined and exposed to the measured temperature.