Industrial automation relies on various control systems that help industries manage complex processes, equipment, and machinery efficiently. Among the most widely used are Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and Supervisory Control and Data Acquisition (SCADA) systems.

These technologies share the common goal of enhancing productivity, reliability, and safety within industrial operations. However, they differ in terms of design, functionality, and application scale.

Understanding these distinctions is essential for selecting the right system for a specific process.

This article explores the main characteristics of each system, their advantages, and how they integrate to form a unified automation strategy in modern industrial environments.

What is a PLC?

A Programmable Logic Controller (PLC) is a digital industrial computer used for specific control tasks.

It is designed for reliability and to replace old relay-based systems. A PLC uses memory to store instructions that perform logic, timing, and sequencing functions.

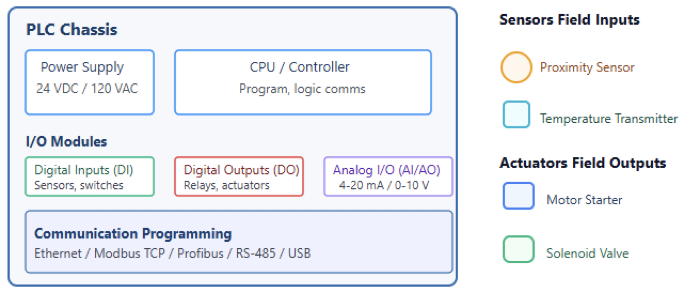

PLC architecture

A typical PLC has a modular design. It includes a power supply, a CPU (Central Processing Unit), and input/output (I/O) modules (See Figure).

CPU

The CPU is the main processor. It interprets input signals and runs the control program.

I/O modules

These connect the PLC to the field. Inputs read sensors or switches, while outputs control actuators, motors, or valves.

Programming software

PLCs are programmed with specialized software using languages like ladder logic, function block diagrams or structured text.

Key characteristics of PLCs

- Discrete control: Best for on/off and repetitive actions, like assembly lines or packaging systems.

- High speed: Provides quick and predictable control cycles.

- Local control: Usually manages one machine or process at a time.

- Cost-effective: Ideal for small-scale control applications.

Advantages and disadvantages of PLCs

Advantages

- Fast and deterministic control for critical tasks.

- Durable and reliable in industrial environments.

- Economical for small to medium systems.

- Easy to program and troubleshoot.

Disadvantages

- Limited scalability for very large processes.

- Becomes harder to manage when many PLCs are networked together.

- Less redundancy compared to DCS.

What is a DCS?

A Distributed Control System (DCS) is a complete control solution for large and continuous processes in one facility.

It uses many local controllers connected through a network, all supervised from a central control room.

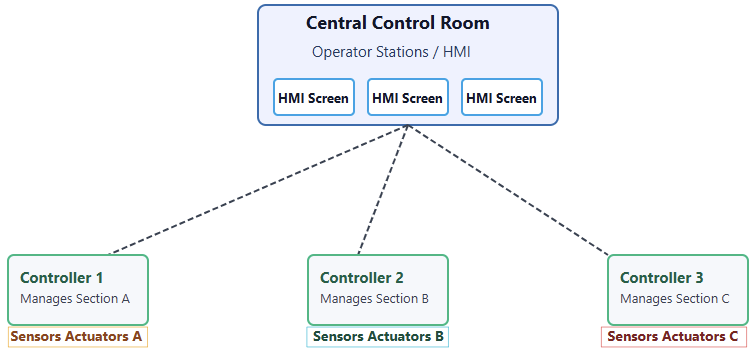

DCS architecture

A DCS uses a distributed architecture to improve reliability and local control.

Controllers

Several intelligent controllers are placed near the process equipment. Each controls a specific loop or area and often includes redundancy.

Control network

A strong, often redundant communication network links controllers to operator stations.

Operator stations

Human-Machine Interfaces (HMIs) in the control room allow operators to monitor and adjust plant operations.

Key characteristics of a DCS

Continuous process control

Ideal for industries such as oil refining, chemicals, or power generation.

Centralized management

Even though control is distributed, supervision is handled from one point.

High reliability

Built with redundancy to ensure continuous operation.

Integrated features

Includes advanced control, trending, and alarm management tools.

Advantages and disadvantages of DCS

Advantages

- Perfect for large, complex continuous operations.

- Highly reliable and fault tolerant due to distributed structure.

- Centralized monitoring of the entire process.

- Pre-engineered and integrated, saving setup time.

Disadvantages

- May respond slower than PLCs in high-speed tasks.

- Expensive to install and maintain.

- Proprietary systems may limit compatibility with other equipment.

What is SCADA?

Supervisory Control and Data Acquisition (SCADA) is a software based system for supervising and controlling processes across wide geographic areas.

It gathers data from remote sites and provides operators with a central interface for monitoring and control.

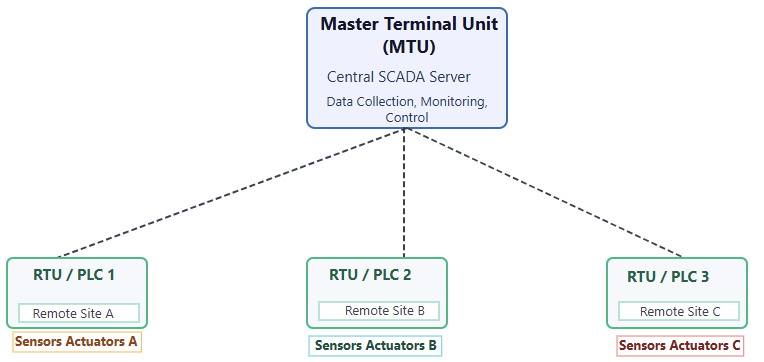

SCADA architecture

A SCADA system has several main parts:

Remote Terminal Units (RTUs) or PLCs

Located at remote sites to collect field data and execute local control.

Master Terminal Unit (MTU)

The central computer or server that communicates with RTUs/PLCs, gathering data and sending commands.

HMI

The graphical interface that shows real-time data, alarms, and allows operator control.

Communication network

Connects the MTU and remote sites using radio, cellular, or internet links.

Key characteristics of SCADA

Supervisory control

Offers an overview of the entire operation, supporting decision making.

Data acquisition

Focused on collecting and storing data for reports and analysis.

Geographically dispersed

Ideal for systems like power grids , water supply or pipelines.

Event-driven

Responds to specific events rather than continuous scanning.

Advantages and disadvantages of SCADA

Advantages:

- Scalable to monitor large, distributed systems.

- Compatible with many hardware and communication standards.

- Strong data logging and reporting abilities.

- Continues functioning even with unstable connections.

Disadvantages:

- Supervisory control can introduce slight time delays.

- Vulnerable to cyber threats due to network dependence.

- Complex setup with varied hardware and software.

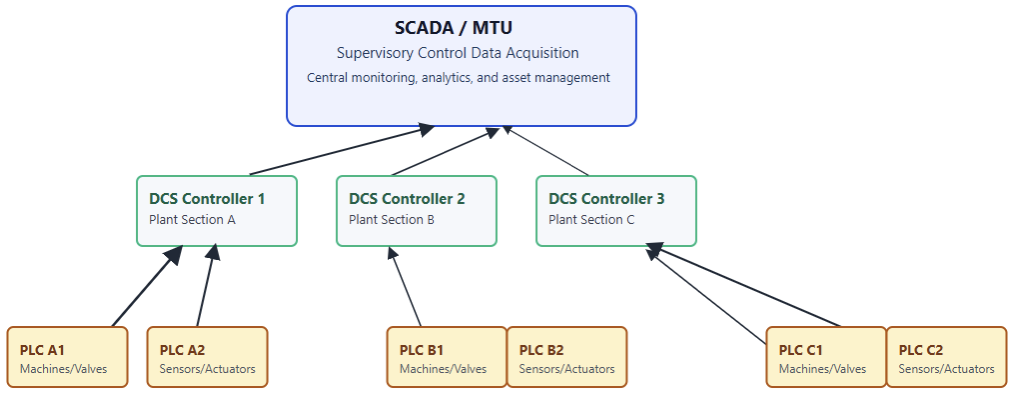

How PLC, DCS, and SCADA work together

In modern plants, these systems are usually integrated instead of working separately. Together they create a multilayered automation structure.

Bottom layer (PLC)

Handles local, fast, and repetitive control for motors, valves, and pumps.

Middle layer (DCS)

Manages coordinated control for continuous processes, often integrating PLCs into its network for better supervision.

Top layer (SCADA)

Provides supervisory monitoring and data acquisition from the DCS and remote PLCs or RTUs. It allows centralized visualization, data analysis, and remote control.

Choosing the right system

Selecting the proper system depends on the process requirements, scale and budget.

Discrete manufacturing

A single PLC or network of PLCs is usually enough and cost efficient.

Continuous, complex processes

DCS suits these environments best because of its high reliability and integrated functions.

Remote, spread-out operations

SCADA is ideal for long distance systems needing centralized monitoring.

Hybrid systems

Many industries combine all three, using PLCs for equipment control, DCS for process coordination, and SCADA for overall supervision. This hybrid setup delivers complete visibility and control.

The Future of PLC + DCS + SCADA

Over time, the differences between PLC, DCS, and SCADA have become less strict. Modern PLCs are more powerful, while DCS and SCADA have become more open and network compatible.

The future points toward increased integration and smarter connectivity.

Increased integration

Data sharing between all layers is becoming standard. This improves transparency and decision making.

Industrial Internet of Things (IIoT)

The IIoT connects more sensors and systems, generating massive data streams for real-time analysis.

Cloud-based systems

Cloud computing allows scalable and flexible SCADA platforms that can be accessed from anywhere.

Cybersecurity

As connectivity grows, protecting networks from attacks becomes a major priority. Strong encryption, access control, and regular updates are now essential.

Key Takeways: PLCs vs DCS vs SCADA

This article introduced the main characteristics of PLCs, DCS, and SCADA. It further explained, their advantages and how they integrate to form a unified automation strategy in modern industrial environments.

From the discussion, it is clear that the PLCs, DCS, and SCADA form the foundation of industrial automation.

Each has its role and strengths. PLCs provide fast, local control for individual machines.

DCS manages complex and continuous operations with high reliability. SCADA offers wide-area supervision and detailed data analysis.

By understanding how they differ and complement each other helps industries build strong automation strategies.

This increases productivity, efficiency, and safety. The best choice depends on the type of process, scale, and available resources.

In many cases, the optimal approach is a combination of the three, using each system where it performs best.

As technology advances, integration between PLCs, DCS, and SCADA will become seamless.

This will enable industries to achieve real-time data visibility, improved decision making and smarter control systems for the future of automation.

FAQ: PLCs vs DCS vs SCADA

What does each of PLC, DCS, and SCADA stand for, and what is their basic role?

PLC

Programmable Logic Controller. It’s a rugged digital device used for local, real-time control tasks, reading inputs from field devices, executing logic, and sending outputs to actuators.

DCS

Distributed Control System. It manages large, continuous or batch processes across a plant, using many controllers distributed physically in the plant, with centralized supervisory control and integration.

SCADA

Supervisory Control and Data Acquisition. It’s more about gathering data from remote or dispersed field devices, providing monitoring and high-level oversight via graphical interfaces and alarms rather than controlling every part of the process directly.

When is a PLC system sufficient, and when might a DCS be better?

A PLC is often enough if you need control of discrete operations or smaller machines (on/off, sequencing) and fast response times.

- A DCS is more suitable when you have large, continuous or batch process requirements (e.g., chemical plants, oil & gas, power generation), many control loops, and you need high reliability, redundancy, and process synchronization.

How is SCADA different from PLCs and DCS in terms of control vs monitoring?

- SCADA focuses on monitoring, data acquisition, event logging, visualization, and remote supervision. It does some control (via RTUs or PLCs), but its central role is not executing high-speed control loops.

- PLCs are about executing control logic in real time. DCS also provides control but adds more integrated, plant-wide, continuous control loops plus supervisory features.

What are the differences in architecture, network, and redundancy among PLC, DCS, and SCADA?

- PLC systems are typically localized, modular; communication may be simpler or more limited; redundancy is possible but often less built-in.

- DCS uses distributed controllers physically spread out, with redundant communication networks, redundant hardware (controllers, I/O, networks), strong integration among components.

- SCADA must deal with geographically dispersed sites; networks may be less reliable; design usually includes strategies to cope with communication delays or failures; redundancy can be present, especially in server or communication paths.

What are typical applications (industries or use-cases) for each system?

- PLC: Machine control, robotics, packaging lines, discrete manufacturing.

- DCS: Continuous process plants (chemical, oil refining, power generation, large scale batch processes) requiring many control loops and high availability.

- SCADA: Utilities (water/wastewater, electricity), pipelines, transport networks, remote monitoring and control over large distances.

What are trade-offs or disadvantages of each?

- PLC: Lower cost, fast, simple for discrete tasks; but less suited to large continuous systems, may lack redundancy and advanced central monitoring.

- DCS: More expensive, may use proprietary protocols, less flexible (vendor lock-in), possibly slower response for discrete/high-speed logic than specialized PLCs.

- SCADA: Latency or delays in control because supervisory; dependency on communication infrastructure; possible vulnerabilities in remote or networked setups; complexity in integrating diverse hardware/protocols.

Can these systems be combined or work together? How?

Yes. Many systems use PLCs at the field/machine level, DCS for larger coordinated control of continuous or batch processes across the plant, and SCADA for supervisory oversight, remote monitoring, analytics, and global operators’ view.

For example, PLCs may handle discrete machine control; DCS handles analog loops, process coordination; SCADA gathers data from both PLCs and DCS, provides alarm and reporting, and allows remote control.

Are PLCs and DCS converging?

Yes. Modern PLCs have adopted features once mostly in DCS: better networking, greater redundancy, advanced control blocks.

Conversely, DCS systems are adopting more open communications protocols and modular architectures that resemble PLC-based installations.

What should be considered when choosing between PLC, DCS, or SCADA for a new industrial project?

Some key factors:

- Process type: discrete, continuous, or batch.

- Scale and complexity: how many control loops, devices, geographical spread.

- Need for redundancy, reliability, downtime cost.

- Speed and determinism of control tasks (how fast response needed).

- Budget, both initial cost and maintenance.

- Integration needs: with other equipment, with data systems, possible remote sites.

- Communication infrastructure and network reliability.