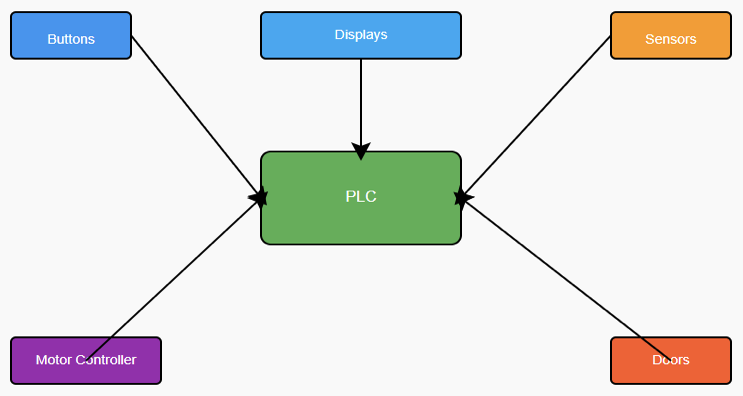

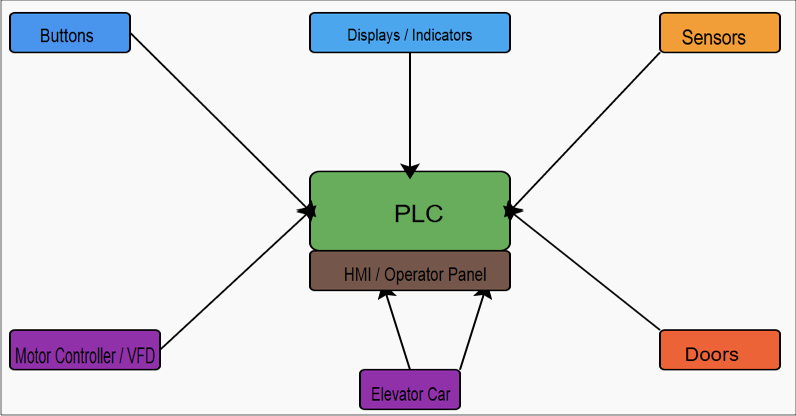

Modern elevators rely heavily on Programmable Logic Controllers (PLCs). A PLC is a digital control device that acts as the main “brain” of the elevator system. It processes signals from buttons, switches, and sensors.

It then executes programmed logic to control motors, doors, and displays. Older systems used hardwired relay logic.

Those were bulky, less reliable, and harder to maintain. PLCs replaced them because they offer greater flexibility, safety, and speed.

The elevator PLC works continuously in a cycle. It scans inputs, executes logic, and updates outputs.

This ensures that passengers move between floors smoothly, safely, and efficiently every second.

This article details the role of PLCs in modern elevators. It indicates how PLC rely elevators work, their key components, their safety features and advantages, how to program them and finally their future.

How a PLC-based Elevator Works: A Step-by-Step Guide

Request handling

The PLC monitors call buttons at all times. When a passenger presses a button, the PLC detects it as an input.

A scheduling algorithm decides which request should be served first for efficiency. The algorithm can choose based on direction, floor priority, or time of request.

This helps reduce waiting time. It also helps save energy by avoiding unnecessary movements.

Input scan

The PLC checks the condition of all input devices. It reads floor requests, door sensors, and car position sensors.

This ensures the system knows what actions are needed. Without continuous scanning, the elevator would not respond quickly.

The input scan runs very fast. It can process hundreds of inputs in milliseconds.

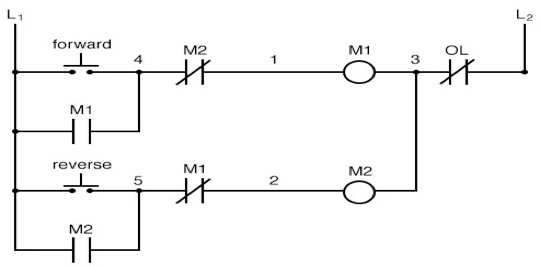

Program scan (logic execution)

The CPU executes the elevator control program. Often, it is written in ladder logic. The program decides the next action based on inputs.

For example, if the button for a higher floor is pressed, the PLC decides the motor must move upward.

The logic also includes safety rules. It prevents the motor from starting if the doors are open. It also checks for overload before allowing movement.

Output scan

After logic execution, the PLC sends commands to output devices. These signals activate motors, door systems, and floor displays.

The output scan translates decisions into real actions. The car moves, the indicators update, and the doors respond. This happens in real time.

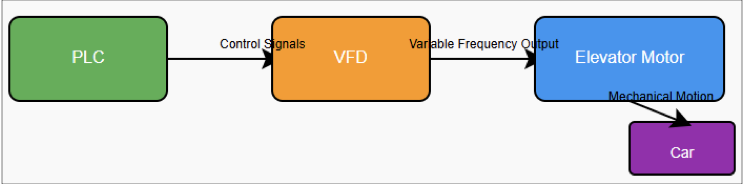

Motor control

A motor controller or Variable Frequency Drive (VFD) receives commands from the PLC.

It adjusts motor speed and direction. This ensures smooth acceleration and braking.

Passengers feel safe and comfortable. Sudden jerks or stops are avoided. VFDs also save energy.

They regulate power use and reduce wear on mechanical parts.

Positioning

Encoders or sensors provide continuous feedback about the car’s position. The PLC uses this information to stop the car precisely at the target floor.

Precision is very important. Even a small misalignment can cause tripping hazards. Accurate positioning improves safety. It also improves passenger trust in the system.

Door operation

When the car levels with the floor, the PLC commands the doors to open. Sensors check if the doorway is clear.

After a delay or when conditions are safe, the PLC closes the doors. Door logic prevents accidents.

If an object blocks the doorway, the doors reopen automatically. This avoids passenger injury.

Repeat

The cycle restarts. The PLC scans inputs again, ensuring non-stop monitoring and control.

This loop is continuous. It happens thousands of times each minute. The constant cycle keeps the elevator responsive at all times.

Key Components of a PLC-based Elevator System

PLC (Programmable Logic Controller)

Acts as the main brain. Connects to input and output modules. Stores and executes the program. Without the PLC, the system cannot function.

Sensors

Detect car position, door status, and load conditions. Provide real-time data. Safety depends on reliable sensors.

Buttons and switches

Provide passenger requests and emergency stop inputs. Simple but essential. Every elevator ride starts with a button press.

Motor drives/controllers

Control the elevator motor’s speed and direction. Allow for smooth travel between floors. Extend the motor’s lifespan.

Door operators

Manage door opening and closing. Ensure safe passenger entry and exit. Often use sensors for obstruction detection.

Indicator displays

Show floor numbers and travel direction. Keep passengers informed and reduce confusion. Some displays include voice announcements.

Human-Machine Interface (HMI)

Helps operators monitor and troubleshoot. Provides diagnostic messages. Can be used to configure system settings.

Advantages of Using a PLC in Elevators

Reliability and durability

Solid-state electronics replace mechanical relays. Fewer moving parts mean less wear. Elevators can run for years with minimal issues.

Simplified troubleshooting

Programs are easier to analyze than complex wiring. Technicians can connect a laptop and view real-time status. Faults are identified faster.

Flexibility and scalability

Functions can be upgraded by changing software. Adding more floors or new features is simple. No need for heavy rewiring.

Cost-effectiveness

Lower long-term maintenance costs. Initial cost is higher, but savings add up over time. Fewer breakdowns mean less downtime.

Compact design

Saves space compared to relay panels. More room is available in the equipment room. Ideal for modern buildings with limited space.

Advanced functions

Can manage multiple cars and optimize movement. Reduces passenger waiting times. Integrates with building systems for energy savings.

PLC Programming for Elevators

Logic rungs

Each rung defines a condition and an action. They resemble electrical circuits. This makes ladder logic easy for engineers to understand.

Inputs and outputs

Left side for inputs, right side for outputs. Clear and organized. Helps link cause and effect directly.

Sequential execution

PLC scans each rung in order. Fast and consistent. All conditions are checked before outputs are updated.

Timers and counters

Control events like door delays and floor counts. Improve accuracy and passenger comfort.

Interlocks

Ensure safe operation by blocking unsafe actions. Prevent accidents such as moving with open doors. Interlocks are critical in every elevator program.

Safety Features in PLC-Controlled Elevators

Redundant systems

Backup processors maintain safety during failure. Reliability is never compromised.

Emergency stop

Immediately halts movement when pressed. Available both inside the car and outside on landings.

Door interlocks

Prevent car movement if doors are not closed. Protects passengers from accidents.

Overload protection

Stops the car if weight limit is exceeded. Alerts passengers to reduce load.

Fire service mode

Sends cars to ground floor during fire alarms. Doors open automatically for evacuation. Firefighters then control cars manually.

Self-diagnostics

Continuously checks system health. Detects issues before they cause failures. Improves preventive maintenance.

The Future of PLC in Elevator Technology

IoT integration

Remote monitoring and alerts for maintenance. Facility managers can track elevators from any location.

Predictive maintenance

Uses data to predict and prevent failures. Reduces downtime and increases safety.

AI optimization

Smarter dispatching and reduced wait times. Systems learn building traffic patterns. Passengers experience faster service.

Enhanced security

Stronger cybersecurity against threats. Protects systems connected to networks.

Wireless communication

Less wiring, more flexibility. Installation is faster and cheaper.

Better HMIs

More graphical, intuitive interfaces. Easy to use for both operators and technicians.

Key Takeaways: PLC in Elevators

This article explained the role of PLCs in modern elevators. It showed how PLC rely elevators work, their key components, their safety features and advantages, how to program them and finally their future trending.

The discussion proved that the PLCs have transformed the way elevators are designed and controlled.

They replaced outdated relay logic with a smarter, safer, and more flexible approach.

A PLC manages every step: from receiving button inputs to controlling motors, positioning the car, and opening doors.

Safety features like overload protection, emergency stop, and fire service mode make modern elevators reliable for passengers.

With IoT, AI, and predictive maintenance, PLC-controlled elevators will only become more advanced.

The combination of precision, flexibility, and safety ensures that PLCs remain the foundation of elevator automation now and in the future.

Elevators are not just mechanical devices anymore. They are intelligent systems powered by advanced control logic.

FAQ: PLC in Elevators

Do real elevators use PLCs, or do they use something else?

Many modern elevators use PLCs for control. Some older systems use relay-based or mechanical controllers.

Are PLC-based elevator systems safe?

Yes. They include safety features such as redundant circuits, emergency stop buttons, door interlocks, and overload sensors.

Codes and standards (e.g. ASME A17.1 in the US) often require strict safety guidelines.

What components of elevator control are handled by the PLC?

The PLC handles logic such as start, stop, acceleration, deceleration, motor direction, door control, position sensing, etc. It also monitors safety sensors.

Do repeated presses of a button do anything?

No, pressing the same floor button multiple times usually has no additional effect once the request is registered. The lamp/light confirms reception.

What programming methods are used for elevator PLCs?

Ladder logic is a common method. It represents logical conditions in rung-based format. Other methods or function blocks might be used depending on PLC type.

Must elevator control PLCs comply with certifications or standards?

Yes. Elevator control systems typically must meet local and international safety and building codes.

Components like brakes, emergency stops, door locks often require certified hardware.

What is the role of sensors in PLC controlled elevators?

Sensors provide feedback to the PLC about elevator position, door status (open/closed), load / overload, obstruction, etc. They are essential for safety and smooth operation.

How is safety redundancy achieved?

Through multiple circuits or processors, backup controllers, and redundant sensors.

If one component fails, another can take over. Also, there may be hardwired safety circuits outside the PLC logic.

Do elevators often use PLCs for all types (traction, hydraulic, etc.)?

Yes. PLCs are used in different elevator types, whether traction or hydraulic. The logic and sensors differ, but the principles are similar.

Is there a cost benefit to using PLCs vs older relay-based systems?

Yes. While initial investment may be higher, long-term savings come from easier maintenance, fewer hardware failures, ability to update features by software instead of rewiring.

What happens if a PLC fails?

In safety-critical installations, there are backup or redundant systems. The PLC usually monitors its own health.

If a failure is detected, elevator must go into a safe state (stop, doors open, etc.). Codes often require this.

Are there limitations to PLC-based elevator control?

Some limitations include the requirement for rigorous safety and certification, potential complexity in programming, need for reliable sensors, and ensuring that software bugs do not lead to unsafe behavior. Also, legacy systems or older installations may not be easily upgraded.