Traditionally, automation control was achieved using relay logic, which relied on physical relays wired together to make decisions. Today, this job is handled by Programmable Logic Controllers (PLCs).

These are specialized industrial computers built for real-time control. PLCs are programmed using specific languages that allow engineers to create control logic. The most famous of these languages is Ladder Logic (LD).

It is a graphical way of programming that looks like old relay circuits. This makes it intuitive for electricians and technicians. Another option is Python. Python is a high-level, general-purpose language.

It was not originally designed for PLCs, but it has become extremely popular thanks to its flexibility. Python usually runs on a PC or industrial computer instead of a PLC.

This article will carefully examine both approaches by highlighting their strengths and weaknesses.

It will also show their differences and explain where each language works best. Finally, it will explore hybrid approaches, which combine the best of both worlds.

Ladder Logic: The Traditional Workhorse

Ladder Logic has a long and respected history in automation. It was specifically designed for electricians, who were already familiar with the wiring of relays and contactors.

Instead of forcing them to learn programming from scratch, Ladder Logic gave them a visual language they could immediately understand.

This visual nature remains its main strength. It allows people to read, follow, and troubleshoot logic without needing deep programming knowledge.

What is Ladder Logic?

A Ladder Logic program is structured like a ladder. On the left and right sides are two vertical rails, just like in an electrical diagram. Horizontal rungs connect these rails, and each rung represents one piece of logic.

Every rung is a logical statement. It contains contacts and coils. Contacts represent conditions or inputs (such as a button being pressed). Coils represent actions or outputs (such as a motor starting).

The PLC scans these rungs continuously in a loop. It reads the state of the inputs, evaluates the logic, and updates the outputs in a fraction of a second.

Advantages of Ladder Logic

Intuitive for electricians

The graphical format is extremely familiar to anyone with an electrical background. Electricians and technicians can quickly see the logic flow without needing long explanations.

Easy troubleshooting

One of the biggest strengths is real-time monitoring. When a program runs, you can see which contacts are “on” and which are “off.” This helps technicians diagnose faults quickly and safely.

High reliability and stability

PLCs running Ladder Logic are robust. They are designed to survive harsh industrial environments like heat, dust, vibration, and electrical noise.

They are also deterministic, meaning they execute tasks on a strict schedule — vital for safety-critical systems.

Wide industry acceptance

Ladder Logic is an industry standard. It is widely taught in schools, and almost all industrial hardware supports it.

This ensures broad compatibility and makes it easier to hire skilled workers.

Suitable for discrete logic

Ladder Logic shines in applications with many on/off decisions, such as conveyor belts, packaging machines, or motor control circuits.

Disadvantages of Ladder Logic

Poor for complex tasks

Handling advanced math, data manipulation, or algorithms is cumbersome. Loops are difficult to implement, leading to long, bloated code.

In such cases, Structured Text or Function Block Diagram might be better choices.

Limited functionality

Ladder Logic was never intended as a general-purpose language. It struggles with advanced networking, string handling, or data analysis.

Can be vendor-specific

While Ladder Logic is standardized under IEC 61131-3, many vendors add their own features. This can lead to vendor lock-in, making it hard to switch platforms.

Less intuitive for software developers

People trained in computer science often find Ladder Logic inefficient. They are more comfortable with text-based coding.

Large programs become complex

As systems grow, so does the ladder diagram size. Large projects can span hundreds of rungs, which makes the program harder to read and maintain.

Python: The Flexible Disruptor

Python is a general-purpose programming language. It was not built for industrial automation, yet its simplicity and versatility have made it extremely attractive in the field.

Today, Python is commonly used on industrial PCs, Raspberry Pi boards, or servers that work alongside PLCs. It is not meant to replace PLCs in safety-critical tasks, but it offers incredible value in handling complex or higher-level processes.

How Python is Used in Automation

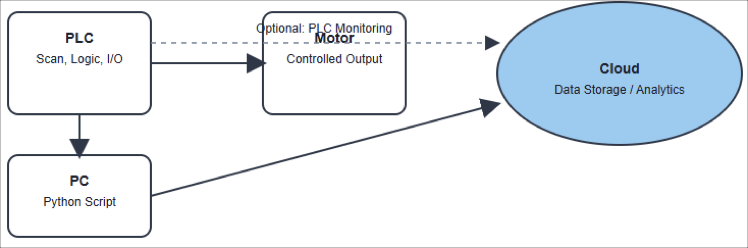

Python does not completely replace the PLC. Instead, it often works side by side with it.

The PLC takes care of real-time control, such as turning motors on and off. Python handles higher-level tasks, such as data logging, analysis, and communication.

This creates what is called a hybrid automation system, where each technology does what it does best.

Advantages of Python

Extensive libraries and capabilities

Python has thousands of ready-made libraries for almost any task. From machine learning to web servers, it has tools that Ladder Logic lacks.

Excellent for complex logic and data

Python handles math, algorithms, and data structures easily. It can process huge datasets, which is difficult in Ladder Logic.

Rapid development and prototyping

Python’s simple syntax makes it quick to learn and fast to write. Prototypes can be built in hours instead of weeks.

Better for connectivity

Python integrates seamlessly with databases, APIs, and cloud services. This is essential for IIoT and Industry 4.0 projects.

Object-oriented capabilities

Python allows code to be modular and reusable. This modern approach makes maintaining large projects easier.

Open-source and cross-platform

Python is free, open-source, and runs on many platforms. This avoids vendor lock-in.

Disadvantages of Python

Not real-time by default

Python is an interpreted language. It is slower and not deterministic, making it unsuitable for safety-critical timing tasks.

Troubleshooting can be harder

Unlike Ladder Logic, Python does not show live “contact status.” Maintenance personnel may struggle with text-based debugging.

Requires programming expertise

Traditional electricians may need extra training to use Python effectively.

Potential for dependency issues

Python projects often rely on third-party libraries, which can create maintenance problems if those libraries stop being supported.

Memory usage

Python consumes more memory compared to PLC code. This is a limitation for embedded devices.

Hybrid Approaches and the Future

The discussion is not about choosing only one. In reality, most modern factories use a hybrid approach.

The PLC remains responsible for mission-critical, real-time control, ensuring machine safety and reliability. Python is used in parallel to manage complex, high-level tasks.

How a Hybrid System Works

In such systems, Python usually runs on a PC or industrial server. It communicates with the PLC through standard industrial protocols such as Modbus TCP or OPC UA.

For example, Python scripts can:

- Collect and analyze data from the PLC.

- Push this data to a central database or the cloud.

- Apply machine learning to predict failures before they happen.

- Generate custom reports and dashboards.

- Connect the automation layer with enterprise systems like ERP or MES.

Evolution and Training

The industrial world is evolving quickly. New software practices like version control, DevOps, and continuous integration are entering automation.

This shift means that companies must train their staff. Maintenance teams who are used to Ladder Logic need exposure to programming concepts.

At the same time, programmers skilled in Python must learn the basics of PLC operation and industrial safety.

This combination of skills is becoming more valuable than ever.

Key Takeaways: Ladder logic vs Python for Automation

Ladder Logic continues to be a dominant force in industrial automation. It is reliable, robust, and easy to troubleshoot for everyday tasks.

Its graphical nature is a huge advantage for technicians working on the factory floor.

However, modern automation now requires much more. Tasks such as data analytics, IIoT integration, and AI-driven insights are common.

These are areas where Ladder Logic struggles. Python, with its flexibility and libraries, provides the necessary power.

The future lies in combining these tools. A hybrid approach provides the reliability of Ladder Logic for machine-level control and the intelligence of Python for higher-level connectivity and analysis. Together, they enable more powerful, smarter, and future-ready automation systems.

FAQ: Ladder logic vs Python for Automation

Can Python replace Ladder Logic completely?

No. Python is not designed for hard real-time control. PLCs with Ladder Logic remain the safest and most reliable option for machine-level operations.

Why do companies still prefer Ladder Logic?

Because it is intuitive, proven, and supported by nearly all industrial hardware. It also matches the skillset of electricians.

Where does Python shine the most?

Python is excellent in data analysis, cloud connectivity, reporting, and advanced features like predictive maintenance or AI.

Do technicians need to learn Python now?

Yes, at least at a basic level. Industry is moving toward digitalization, and Python is a key tool in that journey.

Will hybrid systems become the standard?

Yes. Most factories are already moving in that direction. Hybrid setups give the best balance of safety, reliability, and flexibility.