Effective monitoring and control of equipment in modern industrial automation and process control systems is essential.

These capabilities directly affect productivity and safety. They also influence efficiency.

This can be directly caused by two technologies: one is the Human–Machine Interface (HMI). In addition, another one is Supervisory Control and Data Acquisition (SCADA) systems.

In industrial automation, specifically automation architecture, these terms are absolutely different.

But many technicians and/or some engineers mistakenly use them interchangeably. Indeed, they represent different levels of functionality within an automation architecture.

The ability to pinpoint the difference between HMI and SCADA is very important for technicians and engineers.

Also, for system integrators and decision-making personnel, this knowledge is a must.

This knowledge is especially important when designing industrial control systems. It is also useful during the upgrading and/or maintenance.

This article explains their definitions, architectures, functions, and key differences clearly and practically.

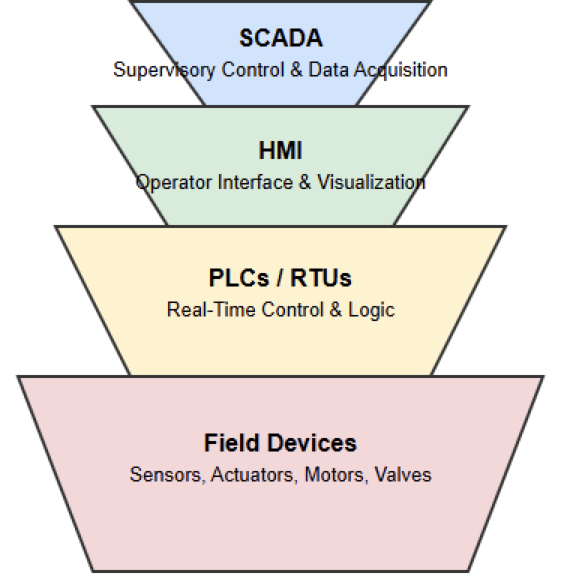

Overview of Industrial Control Systems

Industrial control systems are designed to monitor physical processes and collect data from field devices.

They also enable operators to make informed decisions. We could say that at the lowest level at the lowest level, sensors and actuators interact directly with the physical process. The first ones start the process, while the last ones help to finish it.

Real-time control is taken care of by Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs). This control is based on programmed logic.

Above this layer, visualization and supervision systems provide insight into system behavior.

HMI and SCADA systems operate at this higher level. However, they differ in scope and responsibility.

While both present data visually to users, their scale and complexity vary significantly. Their intended purposes also differ.

Human-Machine Interface

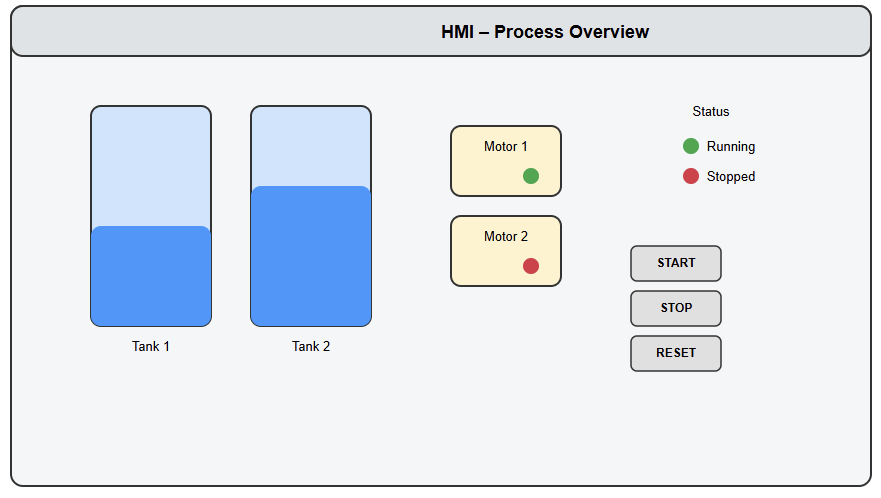

A Human–Machine Interface (HMI) is a user interface that allows operators to interact directly with machines or processes.

Its primary purpose is visualization. It also enables local control. An HMI typically displays real-time data in graphical form.

This data includes temperature, pressure, motor status, alarms, and production counts. The presentation is designed to be easy to understand. HMIs are often deployed on touch panels or industrial PCs.

They may also run on embedded displays located near the equipment. A large number of components can be used by operators on the HMI screen.

These could be input fields, sliders, and buttons. These controls allow them to start or stop motors.

As usual, they also have the ability to adjust setpoints and acknowledge alarms. The HMI communicates directly with one or more PLCs.

This communication uses industrial protocols. Essentially, an HMI provides a visual gateway into a machine or process.

It translates complex control signals into intuitive graphics for human operators.

Characteristics of HMI Systems

HMI systems are typically focused on a single machine or a small section of a plant. Their scope is local rather than plant-wide. They operate in real time. They are also tightly coupled to the PLCs they communicate with.

Most HMIs store little or no historical data. Instead, they rely on live process values. Another defining characteristic of HMIs is simplicity.

Their configuration is generally straightforward. This makes them suitable for machine-level applications.

Typical examples include packaging machines, conveyor systems, and standalone production cells. Because of their limited scope, HMIs are cost-effective. They are also easy to maintain.

What Is SCADA?

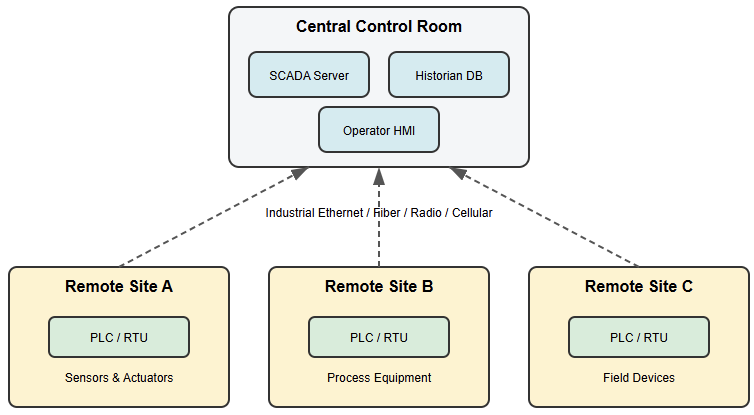

Supervisory Control and Data Acquisition (SCADA) is a computer-based system that allows industries to monitor, control, and analyze real-time data from equipment and processes. It is a comprehensive system designed for large-scale industrial processes. These processes are often spread across wide geographical areas.

A SCADA system provides centralized oversight, while an HMI deals with local interaction. The SCADA systems can monitor multiple machines, production lines, or entire facilities. SCADA systems collect data from many PLCs and RTUs.

They also interface with intelligent field devices. The collected data is stored and processed. It is then presented to operators, engineers, and managers. This presentation takes the form of graphical displays, reports, and dashboards.

SCADA systems also support supervisory control. Operators can issue high-level commands rather than direct machine-level actions. SCADA is commonly used in power generation and water treatment.

It is also widely applied in oil and gas pipelines and large manufacturing plants. The figure below indicates SCADA system architecture, showing multiple remote sites connected to a central control room.

Core Functions of SCADA Systems

One of the most important functions of SCADA is data acquisition. SCADA systems continuously collect large volumes of data.

This data comes from distributed sources. It is made available in real time. The data is typically stored in historical databases.

These databases support analysis, trending, and reporting. Another key function is alarm management. SCADA systems handle complex alarm logic. They support prioritization and logging.

This enables operators to respond effectively to abnormal conditions. Advanced SCADA platforms also include event logging and audit trails.

Redundancy features are often implemented. These capabilities improve reliability and regulatory compliance.

SCADA systems also support remote access. Authorized users can monitor and control processes from centralized control rooms. Access is also possible from remote locations.

Interoperability via PLCs and IIoT

Now, industrial automation is in the era of Industrial 4.0 and IIoT. At this point, HMIs and SCADA systems work together through PLCs and other means.

The PLC serves as a bridge between layers. Data is fetched from the PLC by the HMI and is used for immediate operator adjustments.

At the same time, the SCADA system collects the same data. This data is used to generate system-wide reports. Modern systems increasingly integrate with Industrial Internet of Things (IIoT) platforms.

Edge HMIs process data locally. This reduces latency. Only critical insights are forwarded to Cloud-based SCADA systems. These platforms enable enterprise-wide analysis.

Architectural Differences

The architectural distinction between HMI and SCADA lies mainly in scale and complexity. An HMI usually connects directly to a single PLC. It may also connect to a small group of controllers.

Its architecture is simple, and as usual, in many cases, it operates as a standalone system. A SCADA system has a multi-layered architecture.

It includes data servers and communication servers. Historian databases and application servers are also present.

Client workstations provide user access. Scalability and redundancy are strong prong properties of SCADA architectures. Even if a part of the system fails, this can be ensured by the high availability.

Data Handling and Historian Capabilities

HMIs are designed primarily for real-time visualization. They do not store extensive historical data. Some HMIs retain short-term trends or logs. These are used mainly for diagnostics.

Long-term data analysis is outside the typical scope of an HMI. SCADA systems are built around robust data historians. These historians store processed data for months or years.

This enables trend analysis and performance optimization. Predictive maintenance is also supported. Regulatory reporting is another key function. Some technicians and engineers take SCAD for granted.

But once they deeply dive into it and get some experience, they get to know. For instance, the ability to transform raw data into actionable insights is one of the major advantages of SCADA systems.

User Access and Security

Security requirements differ significantly between HMI and SCADA systems. HMIs usually support basic user authentication. Common roles include operator and maintenance access levels.

Because HMIs are often local, security risks are relatively limited. SCADA systems require advanced cybersecurity measures.

This is due to their centralized nature and remote connectivity. Role-based access control is commonly implemented.

Encryption and secure communication protocols are essential. This is, for example, when it comes to the current world of Industry 4.0 environments. It should be taken into account that audit trails help ensure accountability.

Also, it takes into account regulatory compliance. Then, once these measures are taken help protect critical infrastructure from cyber threats.

Scalability and Integration

HMIs are generally not designed to scale beyond their initial application. Expanding an HMI to cover multiple production areas can be challenging. Such expansion often increases complexity. Maintenance effort also grows.

SCADA systems are inherently scalable. They can integrate hundreds or thousands of devices.

Multiple communication protocols are supported. SCADA systems also interface with higher-level platforms. These include Manufacturing Execution Systems, named MES

Typical Applications

HMIs are commonly used in machine-level and cell-level applications. Examples include CNC machines and bottling lines.

Elevators and pump control panels also rely on HMIs. Their primary role is to provide direct control.

They also deliver immediate feedback to operators. SCADA systems are used when centralized monitoring is required.

They are essential for large-scale data analysis. Power grids and oil pipelines rely heavily on SCADA.

Water distribution networks and large manufacturing plants also depend on these systems. SCADA ensures coordinated operation and system-wide visibility.

Summary of Key Differences

We all agree that both HMI and SCADA provide visualization and control. We should also agree that their differences are significant.

An HMI is a localized interface. It focuses on direct interaction with machines. SCADA is a supervisory system.

It is designed for large-scale monitoring and data management. Coordination is supported across multiple locations. A respective study must be done before making a choice.

Once the study is clear, then the choice between HMI and SCADA creates no complexity. Data requirements and long-term operational goals must also be considered.

Key Takeaways: Difference Between SCADA and HMI

This article addressed the difference between SCADA and HMI by examining their roles and architectures.

Their applications within industrial automation systems were also discussed. Both technologies enable operators to visualize and interact with processes.

Summing field devices and PLCs, then an HMI is best suited for local, machine-level control. SCADA provides centralized supervision and data acquisition. It also supports long-term analysis for large and distributed systems.

Understanding these distinctions helps engineers select appropriate solutions. It also supports performance optimization and future scalability.

FAQ: Difference Between SCADA and HMI

What is the main difference between SCADA and HMI?

HMI is a local operator interface, while SCADA is a centralized supervisory system.

Is HMI part of SCADA?

Yes, an HMI can be a component of a SCADA system.

Can an HMI work without SCADA?

Yes, an HMI can operate independently with a PLC.

What is the primary purpose of an HMI?

To visualize and control a machine or process locally.

What is the primary purpose of SCADA?

To monitor, supervise, and manage large or distributed systems.

Does SCADA store historical data?

Yes, SCADA systems use historians to store long-term data.

Do HMIs store historical data?

Usually no, or only short-term trends.

Which system is more complex?

SCADA is more complex than HMI.