A programmable logic controller (PLC) is a small industrial computer used to automate processes in manufacturing and industrial environments.

Learning how to program a PLC can seem intimidating, especially because most commercial tools are expensive and require specific hardware.

Fortunately, there are several powerful and completely free software options available that are perfect for learning. This article introduces the best free PLC programming software.

It bases on user-friendliness, simulation capabilities, and educational benefits. It also includes practical project examples that help beginners start experimenting with real automation logic.

Using Free PLC Software for Learning

For someone new to industrial automation, free PLC software is the best and safest way to start.

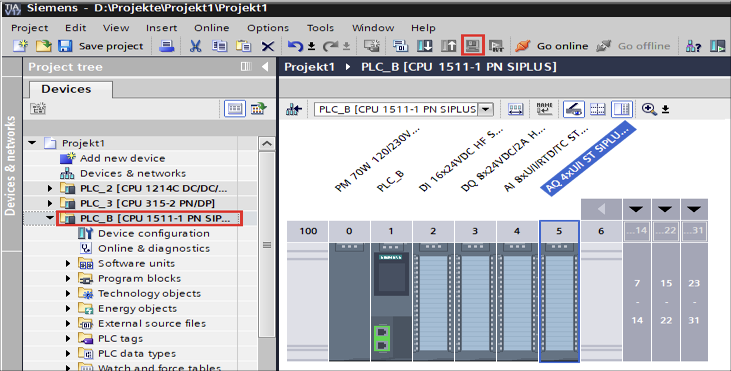

It removes the large financial barrier often associated with commercial systems such as Siemens TIA Portal.

On the other side, Rockwell Studio 5000, requires paid licenses. Free tools allow professionals, students, technicians and hobbyists in training to explore the principles of logic control without investing in costly devices.

In general, a major advantage of these free platforms is their integrated simulators.

Simulation makes it possible to design, run, and test PLC programs virtually (no external hardware needed).

This visual and interactive environment helps learners understand how inputs, outputs, and control logic work together.

By experimenting in simulation, beginners can gain confidence, build solid logic skills, and avoid the fear of damaging real equipment.

Once the basic knowledge is acquired, it becomes easier to transition to real PLCs in industrial settings.

Briefly about PLC Programming Languages

The international standard IEC 61131-3 defines the five main programming languages used in PLCs.

Understanding these languages gives beginners a complete picture of how different control strategies are built.

The Ladder Diagram (LD) is the most common and good to begin with. It looks like an electrical circuit diagram, using horizontal “rungs” with contacts and coils to represent logical relationships. Because it closely resembles relay logic, it is easy for electrical technicians to learn.

The Function Block Diagram (FBD) uses graphical blocks connected by lines that represent data flow. Each block performs a specific function, such as timing, comparison, or arithmetic, making it ideal for continuous and process control.

Structured Text (ST) is a high-level text-based language similar to Pascal or C. It is powerful for advanced calculations, data processing, and control loops. Engineers use it when systems become more complex.

The Instruction List (IL) language is low-level and similar to assembly code. Though now less common, it provides precise control and is still used in performance-critical applications.

Lastly, the Sequential Function Chart (SFC) organizes logic into steps and transitions, allowing programmers to create structured, step-by-step control for sequential processes such as machine cycles or batch operations.

Top Free PLC Software for Beginners

Several high-quality free PLC software platforms make learning easier. Below are six of the most recommended options, each with unique strengths and simple project examples to help you begin.

OpenPLC Editor

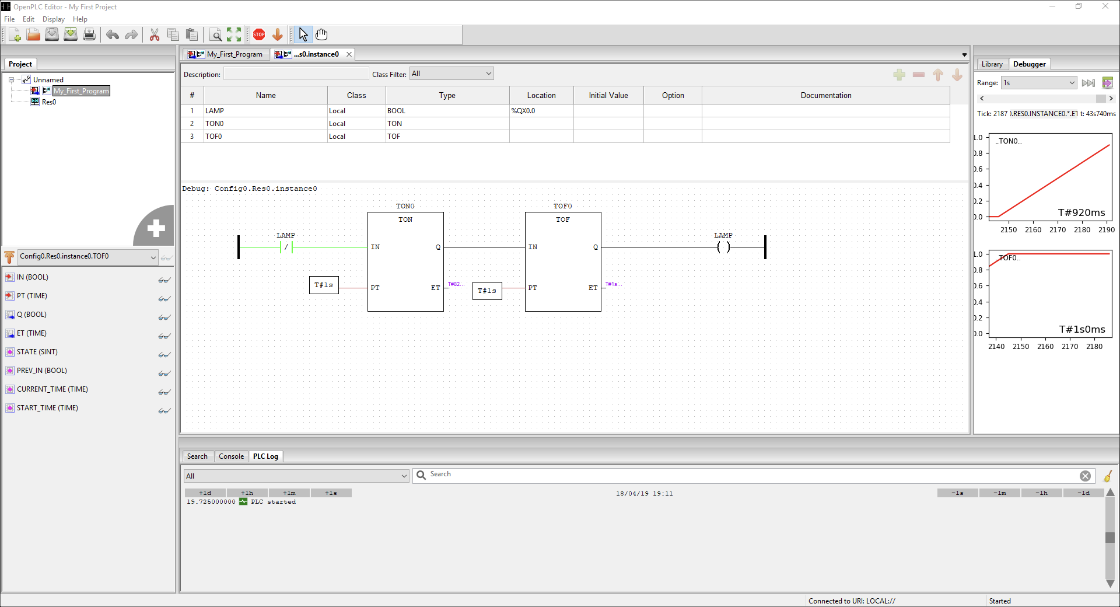

The OpenPLC Project is a completely free and open-source platform that supports all IEC 61131-3 programming languages.

It can be used on multiple operating systems and is compatible with affordable hardware such as Arduino and Raspberry Pi, which makes it an excellent tool for hands-on learning.

OpenPLC includes a powerful built-in simulator where you can test and debug your logic without external devices.

The software’s openness allows you to create projects that can later be transferred to real hardware for further experimentation.

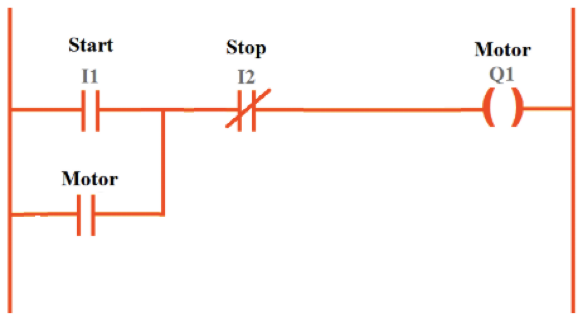

A simple beginner project is a Motor ON/OFF circuit using Ladder Logic. The goal is to make a motor start when a “Start” button is pressed and stop when a “Stop” button is pressed.

The start button energizes the motor coil and latches the circuit so the motor remains on until the stop button is pressed.

In simulation, you can press virtual buttons to observe the motor’s on/off behavior and understand the logic behind industrial control circuits.

Connected Components Workbench (CCW): The Allen-Bradley Gateway

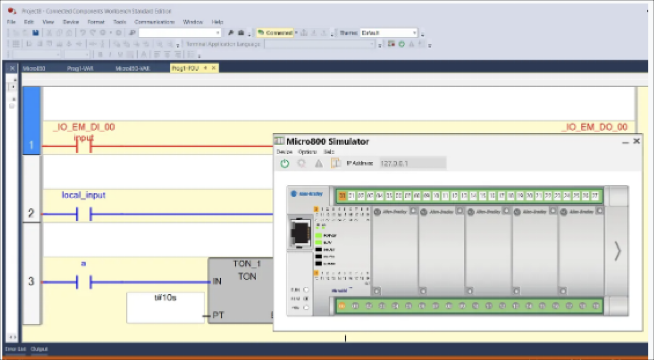

Connected Components Workbench is developed by Rockwell Automation. It is another excellent option for beginners who want to learn within an industrial-grade environment. It is completely free for the Micro800 PLC family.

It also provides the same interface used by professionals in many factories around the world.

The software includes a built-in simulator that allows users to create and test logic without hardware.

It furthermore supports Ladder Diagram, Function Block Diagram, and Structured Text. On top of that it offers flexibility for different programming preferences.

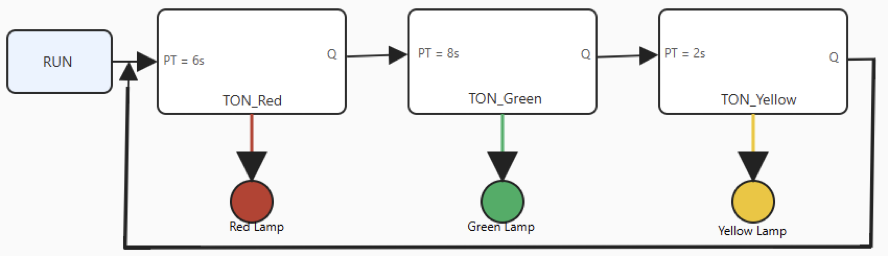

A great introductory exercise is a Traffic Light Sequence project using Function Block Diagram.

The logic involves three lights—red, green, and yellow—that turn on in sequence using timers.

When one timer expires, the next light activates, creating a full traffic signal cycle. Running the simulation in CCW lets learners visualize the timing process and understand how function blocks interact in a real automation system.

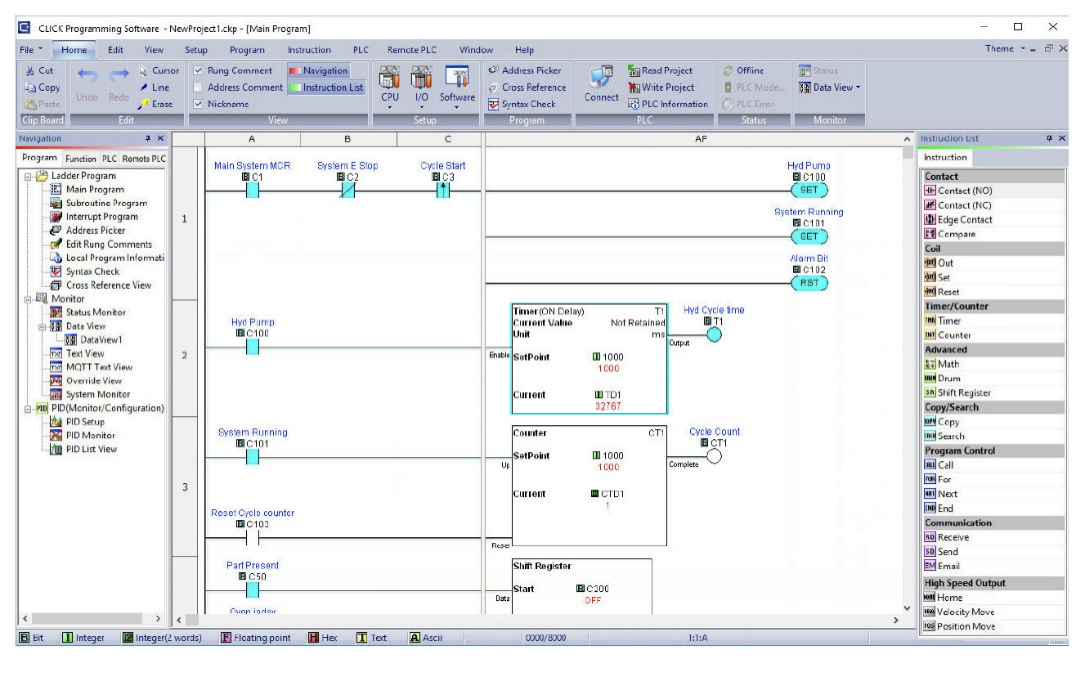

Automation Direct Software

Automation Direct offers multiple free PLC programming tools, each designed to fit a particular product line.

The company focuses on simplicity and quick learning, making its tools ideal for beginners.

The Do-more Designer software provides a friendly interface and includes a built-in simulator.

The Productivity Suite is designed for the Productivity series PLCs and automatically detects I/O modules.

The CLICK Programming Software is especially beginner-oriented and focuses on Ladder Logic, offering a clean and simple design.

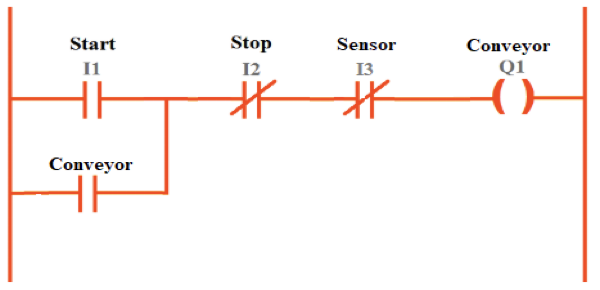

A common learning example is Conveyor Control. The project uses start and stop buttons to run a conveyor motor and a sensor that stops it when an object passes. The logic includes latching contacts for motor control and a normally closed sensor contact.

This contact interrupts the circuit when triggered. Even if simulation is not available in every Automation Direct software version, the simple structure makes it easy to visualize and test the control logic step by step.

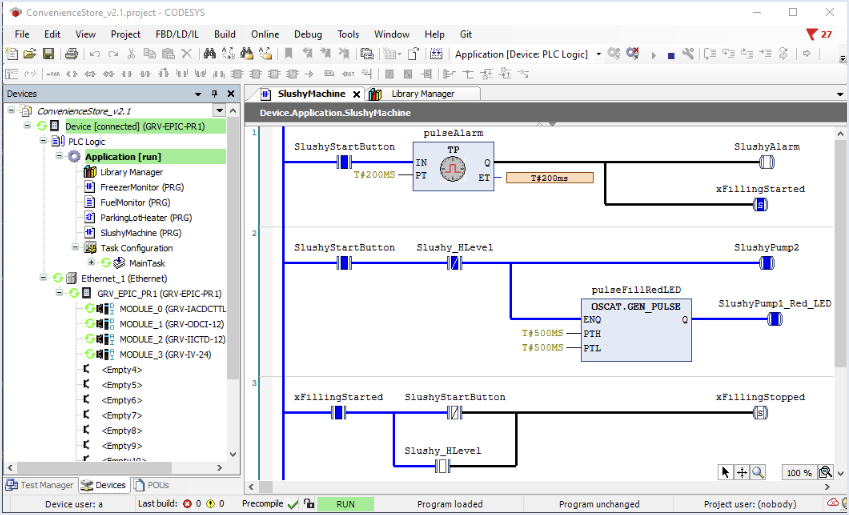

CODESYS

CODESYS is one of the most respected and widely used development environments for PLC programming.

It is vendor-independent and supports all five IEC 61131-3 languages. This makes it an excellent choice for learning universal PLC concepts.

The free version of CODESYS comes with a complete simulator and comprehensive online documentation.

Its structure and features are similar to professional engineering tools used in large automation systems.

It gives beginners valuable experience that can be applied to real industry jobs.

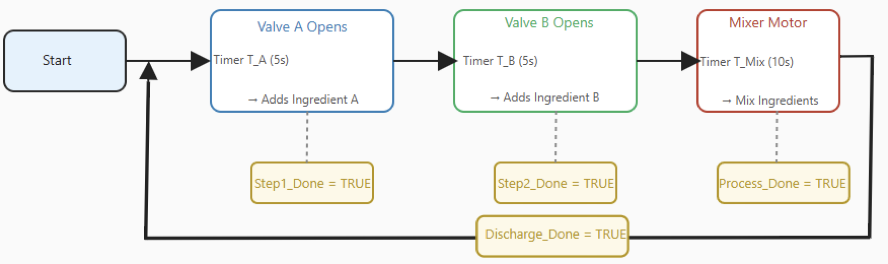

A good introductory project is a Batch Mixing Process using BD. The program defines variables for valves, timers, and motors to control when each component activates. For instance, the first valve opens to add ingredient A.

The closes after a timer expires, and the second valve opens for ingredient B. After both ingredients are added, the mixer motor runs.

The built-in simulator allows you to step through the logic and observe the variable changes in real time.

Siemens LOGO! Soft Comfort

LOGO! Soft Comfort is an easy-to-use tool from Siemens designed for its LOGO! logic modules.

It serves as a gentle introduction to the Siemens ecosystem, which dominates the automation industry.

The graphical interface is based on Function Block Diagrams, making it ideal for visual learners.

The software includes a powerful simulator with 3D visualization, allowing users to see the logic in action.

It also serves as a gateway to the more advanced Siemens TIA Portal used in industrial environments.

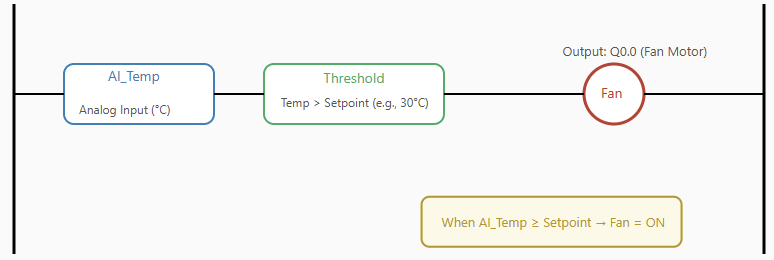

A simple and educational example is an HVAC Fan Control system. The program uses a temperature input connected to a threshold block. This threshold switches the fan ON when the temperature exceeds a certain limit.

By changing the virtual temperature during simulation, users can immediately see how the fan reacts.

The later reinforces their understanding of analog input control and decision-making in automation.

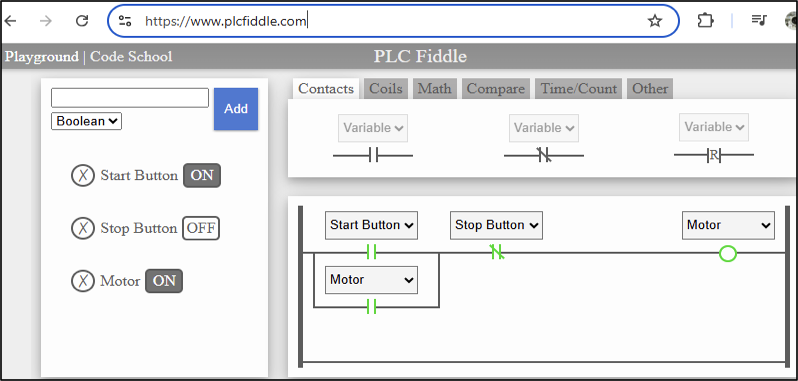

Web-Based Simulators

If you want to practice without downloading software, web-based PLC simulators are a convenient solution.

Tools like PLC Fiddle run directly in a browser and allow you to create, run, and modify Ladder Logic programs instantly.

These platforms require no registration and provide immediate visual feedback. A simple beginner activity is to build AND/OR Logic circuits. In an AND logic example, two inputs must be ON to activate an output.

On the other hand, in an OR circuit, either input turns the output on. Clicking the virtual switches in the browser lets you see the output behavior right away.

This makes it an excellent way to understand logic fundamentals before moving to full PLC environments.

Learning More

Once you become comfortable with these free tools, you can start exploring more advanced learning paths.

Try recreating your ladder logic projects using Structured Text or Function Block Diagram.

It will help to understand how the same logic can be expressed differently. Experimenting with multiple languages builds flexibility and prepares you for professional-level control systems.

You can also move from simulation to hardware by using inexpensive devices such as Arduino or Raspberry Pi. Platforms like OpenPLC can easily interface with these.

It allows you to build real control projects like switching LEDs, motors, or sensors. As your skills grow, consider learning about industrial communication protocols such as Modbus, Profibus, or Ethernet/IP.

These technologies connect PLCs with sensors, HMIs, and other controllers. Software like CODESYS provides an excellent environment to explore these communication systems.

Disadvantages of Free PLC Software

Free PLC software has several disadvantages. It may lack advanced features found in commercial tools. Some versions have limited hardware compatibility, making real-world testing harder.

Free tools often support fewer communication protocols or modules. Updates and technical support are usually slower or unavailable. Documentation can be incomplete, which makes learning more difficult.

Many free simulators are simplified and may not represent real industrial conditions accurately.

Some programs do not allow exporting projects to professional PLCs. User interfaces may feel outdated or less intuitive.

Integration with external hardware or sensors can be limited. Data logging, trend analysis, and network functions may not be included. Certain software may only run on specific operating systems.

Beginners can outgrow these tools quickly and need to switch to paid options. Overall, free PLC software is excellent for learning but not always reliable for professional or large-scale industrial applications.

Key takeaways: Best Free PLC Software for Beginners

This article explained the best free PLC programming software for beginners. It relied on user-friendliness, simulation capabilities, and educational benefits.

In addition, it involved practical project examples that helped beginners start experimenting with real automation logic.

So, from the above studies it can be seen clearly that starting a career in industrial automation does not require expensive software or specialized equipment.

Today’s range of free PLC software provides a complete and professional environment.

The latter is used for learning, practicing, and mastering the essential concepts of PLC programming.

Each of these tools, whether OpenPLC, CODESYS, CCW, or Siemens LOGO! Soft Comfort—offers powerful simulation features and accessible interfaces that make learning both practical and enjoyable.

Hence by choosing the software that best fits your learning style and taking advantage of the free resources available.

You can develop the logical thinking and technical skills required in modern automation.

With patience and practice, these free tools can serve as your foundation for a rewarding and future-proof career in industrial control systems.

FAQ: Best Free PLC Software for Beginners

Which free PLC tools are good for learning?

Popular options include OpenPLC, CODESYS (free IDE version), Siemens LOGO! Soft Comfort (demo mode), and online simulators like PLC Fiddle.

Do these tools support multiple programming languages?

Yes. Many supports IEC 61131-3 languages (Ladder, Function Block, Structured Text, etc.).

Can free PLC software simulate real hardware?

To some degree. Many free tools include simulators to let you test logic virtually. However, simulation may not fully match real industrial conditions.

Are there limitations or restrictions?

Yes. Some tools limit exports, hardware support, or advanced modules. Others restrict saving or runtime features.

Is technical support available for free software?

Generally, support is community-based (forums, user groups). Official support is limited except for paid versions.

Can free software be used on real PLC hardware?

Sometimes. For example, OpenPLC can run on Arduino or Raspberry Pi hardware. But many free tools are best for simulation and learning.

Is free PLC software enough for professional use?

Not usually. You’ll likely need commercial tools for advanced features, high performance, and industrial deployments once you move beyond learning.