A Programmable Logic Controller (PLC) is one of the most critical components in industrial automation.

It serves as the central brain for many machines and systems, constantly processing data and executing commands.

However, when a PLC stops communicating with a PC, serious issues can arise almost immediately.

This failure can lead to unexpected production downtime, delayed operations, and even the loss of important process data.

Troubleshooting such a problem requires patience, attention to detail, and a step-by-step approach.

The causes can range from a faulty cable to misconfigured software, or even hidden network settings.

This article provides a practical and comprehensive guide. It explains how to diagnose and fix communication issues when a PLC refuses to communicate with a PC, while also giving tips to prevent the problem from happening again.

Initial Checks (The Basics)

Check the power supply

A PLC simply will not work without stable power. The first step is to check the power LED indicator on the PLC. Normally, a solid green light shows the unit is receiving power correctly.

If the light is off, there may be an issue. Inspect the power cord to ensure it is firmly plugged in. Also, check for blown fuses or tripped circuit breakers in the panel.

Using a multimeter to measure voltage levels is recommended to confirm that the supply matches the required specifications. Sometimes, even a loose terminal connection can interrupt power flow.

Inspect the communication cables

Communication cables are a common source of problems. They can become loose, bent, or damaged over time, especially in industrial environments where vibration is common.

Inspect both ends of the cable and verify that the connectors are seated properly. Look closely for visible damage, such as frayed wires, bent pins, or worn insulation.

It is also important to confirm that the cable is the right type for the protocol being used.

For instance, Ethernet communication requires a proper Ethernet cable, while RS-232 or RS-485 uses specific serial cables. Using the wrong cable can make communication impossible.

Verify the connection port

A PLC often comes with several ports, including USB, Ethernet, and serial connections.

If the cable is connected to the wrong port, communication will not work. Always make sure the port on the PC matches the one being used on the PLC.

In some cases, the ports may look similar but serve different purposes, so double-checking is vital. Compatibility between the ports is essential for successful communication.

Restart both devices

Sometimes, a very simple solution works best. Restarting the PLC and PC can reset the communication process.

Power both devices off completely, wait for about 10–20 seconds, and then turn them back on.

This action clears temporary glitches, resets internal buffers, and restores network settings to a fresh state.

Many technicians underestimate the effectiveness of a reboot, but it often resolves minor communication errors quickly.

Software and Configuration Problems

Verify software drivers

When connecting through a USB cable, the operating system typically requires a specific driver to recognize the PLC. If this driver is not installed correctly, the communication link will fail.

Ensure that the driver is compatible with your version of Windows, Linux, or macOS.

Outdated or corrupted drivers can also cause failures, so updating or reinstalling the driver may be necessary.

Download the latest version directly from the manufacturer’s website to avoid compatibility issues.

Match communication settings

For serial connections, communication depends heavily on matched settings between the PLC and PC.

These include baud rate, parity, stop bits, and data bits. If even one setting is mismatched, the connection will fail.

Check both the PLC’s programming software and the PC’s device manager to confirm that the values are identical.

Many beginners overlook this step, but it is one of the most common reasons for failed communication.

Check IP addresses and subnet mask

When using Ethernet communication, proper IP addressing is essential. The PLC and PC must be on the same subnet to communicate successfully.

For example, if the PLC IP address is set to 192.168.1.5, then the PC should be set to something like 192.168.1.10, with the same subnet mask (255.255.255.0).

Use the “ipconfig” command on the PC to check its current IP address. If needed, configure a manual IP address for the PC. Subnet mismatches or conflicting addresses on the network can prevent the devices from connecting.

Look for an enabled “autobrowse” feature

Some PLC programming software includes an “autobrowse” or “auto-discovery” option.

This feature allows the software to automatically search for and detect connected PLCs.

If this feature is disabled, the PC may not detect the PLC even if the hardware connection is correct.

Check the software settings and ensure autobrowse is enabled when available.

Check the PLC program and logic

In certain cases, the PLC’s program may include logic or communication instructions that control how it interacts with external devices.

If these instructions are missing or incorrectly configured, communication will fail.

Review the program and confirm that the communication block or instruction is set up properly.

For instance, if the PLC is programmed to only respond under specific conditions, ensure those conditions are being met.

Check for software conflicts

Sometimes, other software running on the PC can interfere with the communication link.

This is especially true for USB devices or virtual COM ports. Close unnecessary applications and try again.

If problems persist, consider reinstalling the PLC programming software. Conflicts between outdated versions of software and drivers can also be a hidden cause.

Ensure firmware is up-to-date

Manufacturers regularly release firmware updates for PLCs. These updates can fix bugs, improve compatibility, and resolve communication issues.

Always check the official manufacturer’s website for the latest firmware version.

Mixing new software with older hardware can lead to unexpected communication problems, so keeping everything updated is a good preventive measure.

Hardware and Environmental Factors

Inspect diagnostic LEDs

Most modern PLCs are equipped with built-in diagnostic LEDs. These lights can provide immediate clues about the system’s status.

For example, a blinking red LED may indicate a hardware fault, while an orange LED could signal communication errors.

Refer to the PLC’s manual for details on what each indicator means. Understanding these signals can save hours of troubleshooting.

Check for electrical noise

Industrial environments often contain large motors, welding equipment, or heavy electrical machinery.

These can generate strong electromagnetic interference (EMI), which disrupts communication signals.

To minimize the impact of EMI, keep communication cables separate from power lines, use shielded cables, and install EMI filters if necessary.

Proper cable routing and protection are key to maintaining stable communication.

Verify ground integrity

Poor grounding can make a system more susceptible to noise and unstable operation.

Check that the PLC, PC, and all connected equipment are properly grounded.

Loose or corroded ground connections can create hidden problems that interfere with communication. A secure and clean grounding system improves both safety and reliability.

Check for component failure

Sometimes, a hardware component itself may be at fault. A defective communication module, port, or network card can prevent successful communication.

If other troubleshooting steps do not work, test the PLC with a replacement module or adapter.

Many manufacturers provide diagnostic tools that can help identify faulty hardware components.

Check environmental factors

PLCs are designed to handle tough industrial environments, but extreme conditions can still cause failures.

Heat, dust, and moisture are common culprits. Ensure the PLC is installed in a cool, dry location with adequate ventilation.

If the environment is particularly harsh, use protective enclosures rated for industrial use. Regular cleaning and inspection can also extend the equipment’s life.

Advanced Troubleshooting Techniques

Use network monitoring tools

For Ethernet-based communication, network analyzers or monitoring tools can provide valuable insight.

These tools allow you to view traffic, identify packet loss, detect collisions, or measure delays.

In complex networks with multiple devices, these tools can quickly pinpoint the source of communication issues.

Check diagnostic buffers

Most PLC programming environments provide access to diagnostic buffers or logs.

These logs contain detailed information about system events, warnings, and errors.

Reviewing the diagnostic buffer can help identify when and why communication was interrupted. This information is often more precise than LED indicators alone.

Monitor CPU load and memory

A PLC with an overloaded CPU or insufficient memory may struggle to maintain communication.

Check the scan cycle time to ensure it falls within the manufacturer’s recommended range.

High CPU load can result from inefficient programming or too many simultaneous tasks.

Optimizing the PLC program may improve performance and restore stable communication.

Try a different PC

In some cases, the issue may not be with the PLC but with the PC itself. Problems such as a faulty USB port, outdated network card driver, or even malware can block communication.

To test this, try connecting the PLC to a different laptop or workstation. If the new PC establishes communication successfully, the problem lies with the original computer.

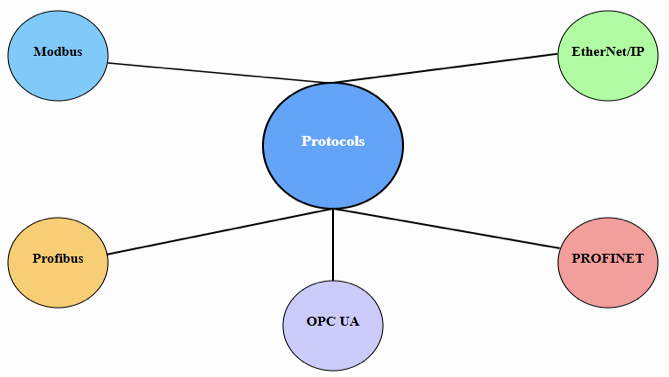

Common Communication Protocols

Understanding the protocol is key

Different PLCs use different communication protocols, and troubleshooting depends on understanding which one is in use.

Each protocol has unique requirements, such as cable type, port settings, or software configuration.

Ethernet/IP is common

This protocol uses standard Ethernet infrastructure, such as cables, routers, and network switches.

Correct configuration of IP addresses, subnet masks, and gateways is essential. Many modern industrial networks rely on Ethernet/IP for its speed and flexibility.

Modbus is a popular protocol

Widely used in industrial automation, Modbus can operate over serial or Ethernet connections.

For Modbus RTU (serial), the baud rate, parity, and stop bits must all match between devices. For Modbus TCP (Ethernet), correct IP settings are required.

Its simplicity makes it a favorite for connecting multiple devices across different brands.

RS-232 and RS-485 are serial protocols

These are older but still reliable communication standards. RS-232 supports point-to-point connections, while RS-485 supports multi-drop connections with multiple devices. Both require specific wiring and pin configurations.

Understanding the correct pinout is critical for proper operation.

Documentation and Best Practices

Always keep documentation

Maintaining up-to-date wiring diagrams, configuration notes, and network maps is essential.

Document every change made during installation and troubleshooting. Having this information on hand saves significant time during future repairs and helps new technicians understand the system quickly.

Back up your program

Always create and store backups of the PLC program. This provides a safety net in case of memory corruption or accidental deletion.

Keep backups stored securely, both locally and in cloud storage, so they are accessible whenever needed. Regularly updating backups is a habit that prevents data loss.

Use quality materials

High-quality communication cables, connectors, and power supplies may cost more upfront but greatly reduce the risk of failure.

Cheap or poorly shielded cables are more likely to degrade and cause intermittent communication errors.

Investing in good-quality components improves long-term reliability.

Train personnel

Human error is a common cause of communication failures. Properly training staff in installation, programming, and troubleshooting procedures is crucial.

Training sessions should cover safety practices, use of diagnostic tools, and handling of hardware components.

Skilled personnel can often solve issues faster and prevent mistakes before they happen.

Perform regular maintenance

Preventive maintenance goes a long way toward reducing unexpected failures. Periodic inspections of cabling, connectors, power supplies, and environmental conditions help detect small issues before they grow into major problems.

Cleaning dust, tightening terminals, and checking ventilation are simple but effective maintenance steps.

Key Takeways: PLC Not Communicating with PC – How to Fix

This article explained how to diagnose and fix communication issues when a PLC refuses to communicate with a PC. It also gave some tips to prevent the problem from happening again.

So, from the discussion we learned that troubleshooting a PLC that refuses to communicate with a PC requires careful observation and logical steps.

We should begin with the basics—checking power supplies and communication cables.

Next, examine software drivers, IP settings, and protocol configurations. Finally, look into hardware reliability, grounding, and environmental conditions.

A structured and systematic approach minimizes downtime and ensures faster recovery.

Following best practices such as documentation, program backups, and regular maintenance helps prevent many issues from occurring in the first place.

By applying these methods, communication between PLC and PC can usually be restored quickly, allowing operations to return to normal.

FAQ: PLC Not Communicating with PC – How to Fix

My PC doesn’t detect the PLC—what could be wrong?

First, check your physical connection: ensure Ethernet cables are securely connected and the link lights on your PLC are active. If LEDs aren’t active, the cable or port may be faulty.

Ethernet is plugged in—what next?

Verify that your PC’s network interface is configured accurately and assigned to the correct local network.

One experienced user recommends: Ensure your PC’s network interface is plugged in and has an IP on the expected PLC subnet.

Why does FactoryTalk Linx fail to find devices on the network?

Confirm that your PC’s IP is on the same subnet as the PLC since the driver only searches its own subnet.

If the driver uses the wrong network adapter (e.g. Wi-Fi instead of Ethernet), you may need to specify the correct interface under driver configuration in FactoryTalk.

Could certificates or time settings cause connection issues (e.g., TIA Portal / HMI)?

Yes, as in scenarios involving Siemens devices, mismatched or untrusted certificates can block communication.

Any special steps for USB-based connections (e.g., Schneider Modicon PLCs)?

Yes, if your Modicon PLC isn’t recognized over USB, confirm that the “PLCUsb” Windows service is running and that the correct driver version (signed by Microsoft) is installed.

Could environmental or hardware issues affect connectivity?

Absolutely. Key factors include: Power stability, EMI or electrical noiseand/orI/O module failures.

What common communication resolutions do technical articles suggest?

Excellent troubleshooting suggestions from Kwoco-PLC include: Inspecting and replacing damaged Ethernet cables or connectors; Verifying that configuration settings—such as IP, subnet mask, and gateways—are accurate; Ensuring protocol compatibility and keeping firmware/software updated; Using diagnostic tools and manufacturer documentation when deeper analysis is required.