A Programmable Logic Controller (PLC) is the brain of an automated system. It controls machines and processes.

When a PLC goes into a fault mode, it stops operating. This can cause a complete shutdown of production.

In modern industries, even a few minutes of downtime can cost thousands of dollars in lost revenue, wasted materials, and missed deadlines.

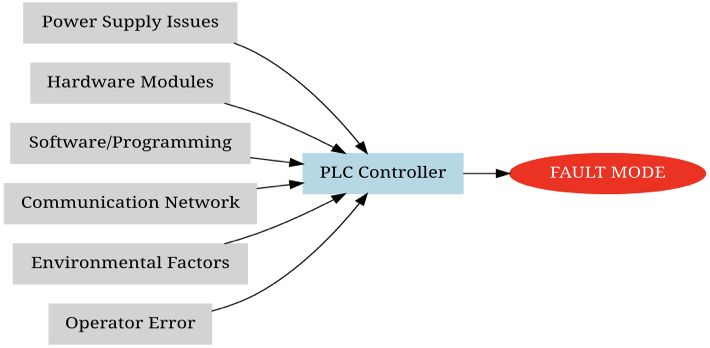

This article explains the many reasons a PLC might fault. The causes can be grouped into several categories.

These include power, hardware, software, and environmental issues. Operator mistakes and communication failures also play an important role.

What Causes a PLC to Go into Fault Mode?

Understanding these issues is key to effective troubleshooting. With proper knowledge, technicians can minimize downtime, extend equipment lifespan, and ensure safer operations.

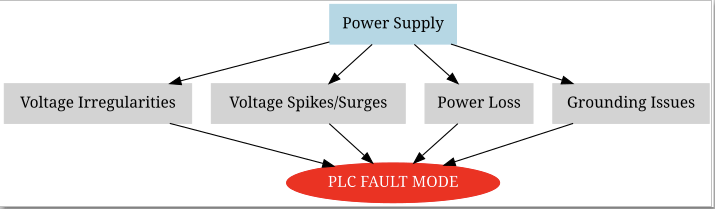

Power Supply Problems

A stable power supply is critical for a PLC. Without clean and reliable power, even the most advanced controller will eventually fail.

Voltage Irregularities

The PLC needs a specific voltage. Overvoltage or undervoltage can stress components.

This can cause damage over time. For example, a PLC rated for 24V DC may malfunction if supplied with fluctuating voltage between 18V and 30V.

Sensitive components such as the CPU and memory modules are highly vulnerable to such irregularities.

Voltage Spikes and Surges

Sudden spikes in voltage can damage internal circuits. These can be caused by lightning, large motors starting, or heavy loads switching on and off in the same network. Surge protectors and line filters are often installed to reduce this risk.

Unstable Power Sources

Fluctuating power from an unstable source can weaken the PLC’s reliability. This is common with backup generators or poor-quality inverters.

A fluctuating frequency or unstable waveform can also affect the PLC’s timing functions.

Grounding Issues

Poor or missing grounding is a major cause of problems. It creates electrical noise. This noise can corrupt data or interfere with communication.

In addition, improper grounding may increase the risk of electric shock and fire hazards.

Power Loss

A sudden power loss can cause memory corruption. This can cause the program to be lost.

Many PLCs include battery-backed RAM or non-volatile memory, but frequent power failures still reduce system reliability.

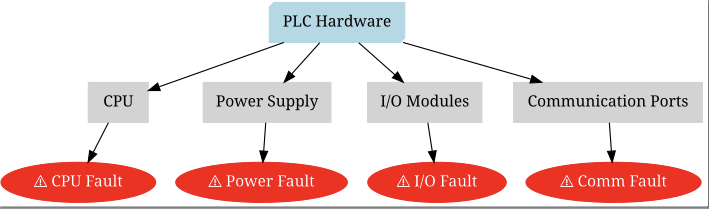

Hardware-Related Issues

The PLC is made of many hardware parts. If any part fails, the entire system can be affected.

Component Failure

Like any electronic device, components have a lifespan. Capacitors, connectors, and fans can wear out over time.

A component failure can trigger a fault. For example, a failed cooling fan may cause overheating that damages the CPU.

I/O Module Failure

The PLC’s input/output (I/O) modules connect it to sensors and actuators. A failure in an I/O module is a common fault source.

This can be due to a short circuit, blown fuse, or physical damage. Loose terminal blocks or damaged wires can also cause I/O problems. A single bad sensor connection may be enough to shut down a line.

Aging Hardware

Older PLCs are more prone to failure. The components inside degrade over time. This can lead to decreased performance and faults.

Capacitors dry out, solder joints weaken, and connectors become less reliable. Preventive replacement programs are essential for legacy systems.

Physical Damage

Vibrations from heavy machinery can loosen internal components. Drops, impacts, or rough handling during maintenance can cause unseen damage.

Cracked circuit boards may still function for a while but eventually lead to intermittent faults.

Loose Connections

A loose wire or connector can cause an intermittent signal. This can cause the PLC to fault. Periodic inspection of wiring and tightening of terminals can prevent many issues.

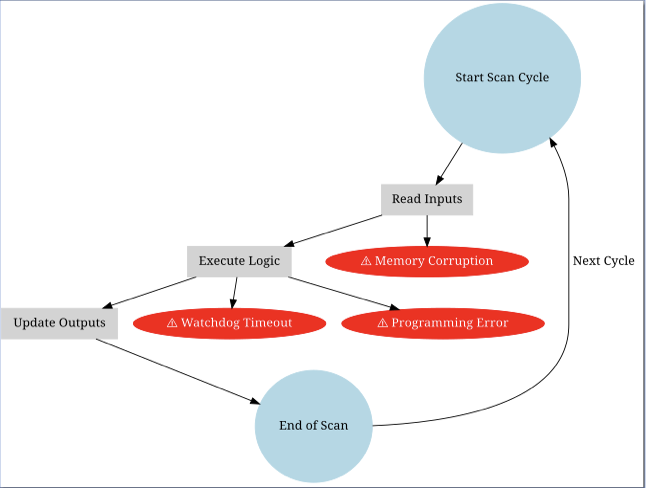

Software and Programming Faults

Errors in the PLC’s programming can cause faults. The software is as important as the hardware.

Programming Errors

A small coding mistake can crash the system. Bugs may go unnoticed until a specific operation is triggered.

For example, a missing reset condition in a timer could cause endless loops or watchdog expiration.

Memory Corruption

Electrical interference or power issues can corrupt the PLC’s memory. This can make the program unreadable by the CPU.

Corrupted memory blocks may cause unpredictable machine behavior, creating safety risks.

Watchdog Timer Expiration

The PLC has a watchdog timer. This timer monitors the scan cycle. If the program takes too long to execute, the timer expires.

This causes a fault. Infinite loops, too many nested subroutines, or heavy calculations can trigger this problem.

Firmware Issues

Outdated or incompatible firmware can cause system glitches. This is especially true when updating hardware.

A mismatch between the CPU firmware and I/O firmware can result in errors or crashes.

Incorrect Configuration

Incorrectly configured I/O modules can cause communication problems. This can result in inaccurate readings or data.

Misassigned addresses, wrong data types, or unconfigured modules are common mistakes.

Conflict with Other Components

An incompatible device added to the system can cause a fault. The PLC might not be able to understand the device.

For instance, adding a high-speed encoder without enabling high-speed counters can trigger errors.

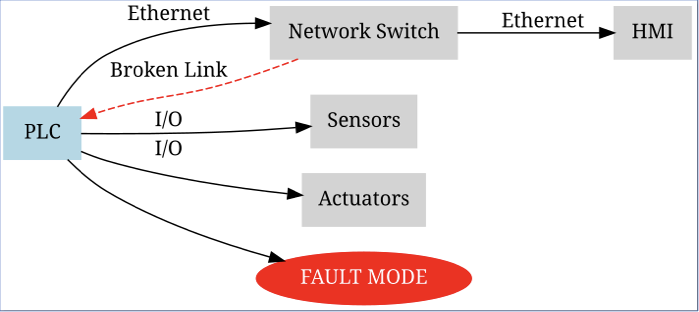

Communication Network Problems

Modern PLCs rely on networks. Communication ensures data flows smoothly between devices.

Communication Loss

The loss of communication between the PLC and other devices can trigger a fault. This can affect HMIs, other PLCs, or network peripherals. In distributed control systems, this issue can bring entire plants to a halt.

Faulty Cables

Damaged or loose Ethernet cables are a common cause. They can lead to data loss or dropped connections.

Over time, repeated bending or exposure to harsh environments weakens cable shielding.

Incorrect Network Settings

Misconfigured IP addresses or network settings can prevent devices from communicating.

A duplicated IP address can cause severe conflicts in industrial Ethernet networks.

Network Congestion

A high volume of network traffic can cause delays. This can lead to communication timeouts and faults. Overloaded switches or poorly designed topologies contribute to congestion.

Environmental Factors

The operating environment can severely impact PLC. Industrial settings often expose controllers to harsh conditions.

Heat

Excessive heat is a major problem. Overheating can damage the CPU and internal components.

Poor ventilation or a malfunctioning cooling fan can cause heat buildup. Installing PLCs in climate-controlled cabinets helps mitigate this risk.

Humidity and Moisture

Moisture inside the PLC cabinet can short circuits. Condensation is a risk in humid environments.

Protective enclosures with proper IP ratings are recommended for outdoor or washdown areas.

Dust and Dirt

Accumulation of dust can insulate components. This can prevent cooling and cause overheating. Conductive dust particles can also cause short circuits.

Electromagnetic Interference (EMI)

Electrical noise can corrupt data and interfere with signals. Large motors, welding machines, or variable frequency drives can be a source of EMI. Shielded cables and proper grounding reduce the effect.

Corrosive Substances

Corrosive substances in the air can degrade electronic components. Factories that handle chemicals, acids, or saltwater environments must use protective coatings and sealed cabinets.

Operator Error

Human actions can lead to a PLC fault. Even with advanced automation, human error remains one of the top causes of downtime.

Incorrect Data Entry

An operator entering wrong data can trigger an unexpected event. For example, entering the wrong temperature setpoint may exceed process limits and cause faults.

Accidental Program Modification

An operator might accidentally change a program variable. This could cause the process to behave unpredictably. Without proper access control, inexperienced staff may introduce errors.

Improper Handling

Not handling the PLC or modules correctly can cause damage. This includes plugging and unplugging modules incorrectly.

Static discharge, bending connector pins, or forcing modules into slots can all result in faults.

Key Takeways: What Causes a PLC to Go into Fault Mode?

A PLC entering fault mode is a serious issue. It points to a problem that needs attention.

The cause can be simple, like a loose wire. It can also be complex, like a corrupted program. A systematic troubleshooting approach is essential.

Start with the most basic checks. Look for obvious problems like power and connections.

Then, use software diagnostics to find the root cause. Many PLCs provide diagnostic LEDs, error codes, or built-in diagnostic tools to guide maintenance staff.

Regular maintenance and proactive replacement of aging parts can prevent many faults.

Proper operator training, software version control, and environmental protection also play critical roles.

Understanding these potential issues helps keep industrial processes running smoothly and reliably.

Ultimately, fault prevention is less costly than fault recovery, making preventive strategies a smart long-term investment.

FAQ: What Causes a PLC to Go into Fault Mode?

What typically causes a PLC to enter fault or stop mode?

Several factors can trigger a PLC to enter fault mode or stop mode, effectively halting its operation:

Module failure, power outages, and network issues are among the most common triggers; Environmental conditions, such as overheating, moisture, and electromagnetic interference (EMI), also play a significant role; Electrical failures including power surges, voltage fluctuations, and short circuits can directly lead to faults; Software glitches like programming errors, memory corruption, or firmware incompatibilities may also cause the system to fault.

Which root causes are most frequently observed in PLC faults?

Field device problems, input/output (I/O) module failures, and power supply issues account for approximately 80% of all PLC failures; Grounding issues can introduce electrical noise that causes erratic behavior or faults.

How should I approach troubleshooting a PLC that has entered fault mode?

A structured, step-by-step diagnosis is critical:

- Check basics first: Inspect power supply, wiring, connections, and ensure input/output modules are functioning correctly.

- Use diagnostic tools: Refer to the PLC’s fault code or LED indicators; programming environments often provide error descriptions to guide troubleshooting.

- Reset and reload: Power cycle the PLC, reload the program from a verified backup, and check if the fault persists.

- Inspect hardware: Physical inspection of the PLC, including the CPU, I/O modules, and power modules, can help identify failures.

- Check communication systems: Network misconfigurations, damaged cables, or incompatible firmware can also cause faults.

What are the less obvious or extended causes of PLC faults?

Watchdog timer expiration, program download or memory mismatch, hardware inputs for stop/run controland/ormathematical overflow faults.

Do internal fault-handling routines affect how the PLC responds to errors?

Yes. For example, on Allen-Bradley systems: Minor faults (like low battery warnings) don’t stop the PLC and are often just logged; Recoverable major faults can be handled via user-defined fault routines (fault handlers), allowing the PLC to potentially recover and continue operation; non-recoverable major faults— checksum errors—cannot be recovered from with a fault routine and will cause the PLC to fault and stop.