We use simulation to virtually test and analyze designs, systems, and processes. This helps to improve safety, efficiency, and cost effectiveness and reduce the need for physical prototypes.

Simulation ensures that product will function as intended in real-world conditions. This digital approach allows for faster iteration, exploration of various design options, and prediction of potential issues before committing to expensive manufacturing.

Running PLC code on a simulator before loading it into real hardware is one of those things that can save us hours of frustration. That is why important to make a good choice of which software to use

So, this article describes the best simulation tools available, highlight what each one does best, and share some practical advice to help you choose the right fit for your situation.

Criteria for a Good PLC Simulator

Simulation platforms are developed with different objectives. Some are specifically designed for educational environments, others are intended for advanced industrial validation, while several serve as a bridge between the two. The following are key aspects that merit attention, based on:

First, Realistic runtime: The best simulators must behave like an actual PLC. It completes with scan cycles, CPU load, and communication stacks. This realism is crucial when you need to validate logic under near-production conditions.

Second, Integration with IDEs: If the simulator runs directly inside your programming environment such as, TIA Portal, Codesys, or Studio 5000, you won’t waste time copying projects back and forth.

Third, Connectivity options: Real projects rarely run-in isolation. Having virtual Modbus, Profinet, or EtherNet/IP endpoints allows you to test how your logic interacts with HMIs, SCADA, and other devices.

Fourth, Visualization: For training and debugging, being able to “see” sensors, conveyors, and actuators in action makes the whole process far more engaging.

Fifth, Automation support: If you’re running repeated tests (like regression checks), scripting or APIs let you run simulations automatically rather than by hand.

Sixth, Licensing and cost: Some tools are open-source and free, while others are tied to expensive vendor ecosystems. Often, your budget (or your customer’s hardware choice) will narrow the field.

The Best Tools in 2025

Our research found that the best tools by 2025 are:

First, Siemens S7-PLCSIM / PLCSIM Advanced: best for Siemens users who want near-perfect virtual controllers.

Second, CODESYS with simulation runtime: best for portability and multi-vendor learning.

Third, Factory I/O + connectors: best for classrooms, training labs, and visual learners.

Fourth, OpenPLC: best free, open-source option for students and hobbyists.

We are going to discuss about them one-by-one.

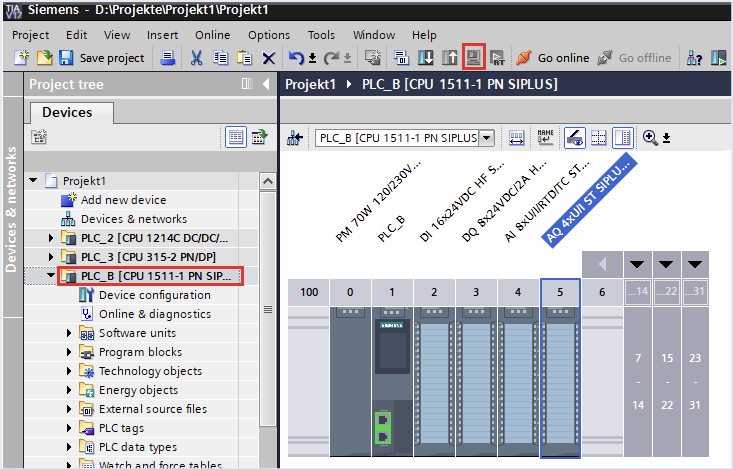

About Siemens S7-PLCSIM / PLCSIM Advanced

PLCSIM, and PLCSIM Advanced, give you a virtual version of an S7 controller right inside TIA Portal. That means you can load the exact compiled program you’d run on a real S7-1200 or S7-1500, complete with I/O and communication options.

Why Yes: If your plant runs on Siemens’ hardware, this simulator is the most faithful digital stand-in. It’s great for checking logic, testing HMI interactions, and even simulating faults.

Why No: It’s very much tied to Siemens’ ecosystem. If you’re programming for other vendors, it won’t help you much. It’s also a licensed product, so it comes with a price tag.

Best for: Training centers working in Siemens, Integrators or commissioning engineers only environments.

Extra: Make sure your TIA Portal release is being matched by your version of PLCSIM. You can set up virtual Ethernet interfaces to connect to HMIs or OPC servers for realistic network tests.

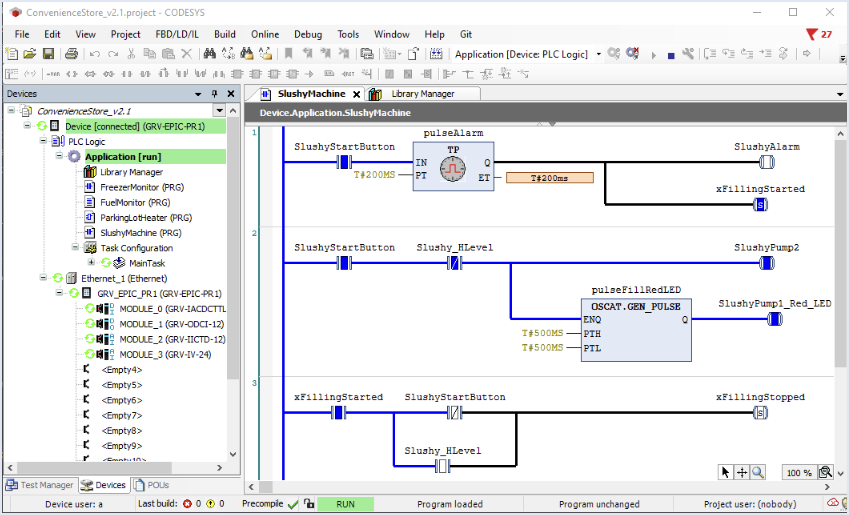

CODESYS (IDE + Runtime)

CODESYS has become a household name in the automation world because it’s vendor-agnostic.

You can use it to program devices from WAGO, Festo, Beckhoff variants, and countless OEMs.

Built into the IDE is a solid simulation feature, so you can run your project without needing real hardware.

Why Yes: Portability. You can learn IEC 61131-3 programming in one place and later move your project to different hardware with minimal adjustments. It’s also widely used in academic programs.

Why No: While the simulation is good, you may still need hardware-in-the-loop testing to check specific timing or vendor-specific features.

Best for: Engineers working in environments where multiple hardware brands are in play, educators or students.

Extra: Use the built-in “softPLC” runtime for local testing, and try adding visualization objects to simulate HMI integration right in the IDE.

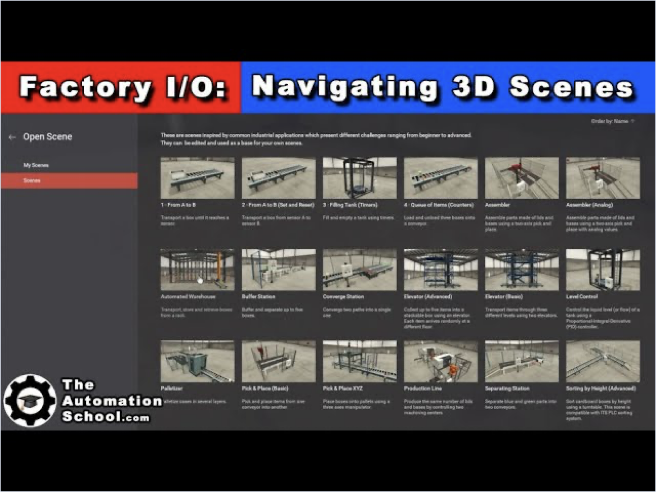

Factory I/O

Factory I/O isn’t a PLC programming environment, instead it’s more like a 3D virtual factory that you can connect your PLC or softPLC to. Think of conveyor belts, sensors, motors, and robots you can control with your ladder logic.

Why Yes: The visual aspect makes learning and debugging far easier. You can literally see the effect of your program on a conveyor or robotic arm, which is great for teaching and training.

Why No: Since it’s not a PLC IDE, you’ll still need another tool (like OpenPLC, PLCSIM, or Codesys) to actually run the logic. Some users also find the licensing a bit expensive for classroom setups.

Best for: Anyone who benefits from a visual, hands-on simulation environment, training labs, or classrooms.

Extra: Pair Factory I/O with OpenPLC for a cost-effective learning setup. Connect the two via Modbus/TCP and start experimenting with ladder logic sequences right away.

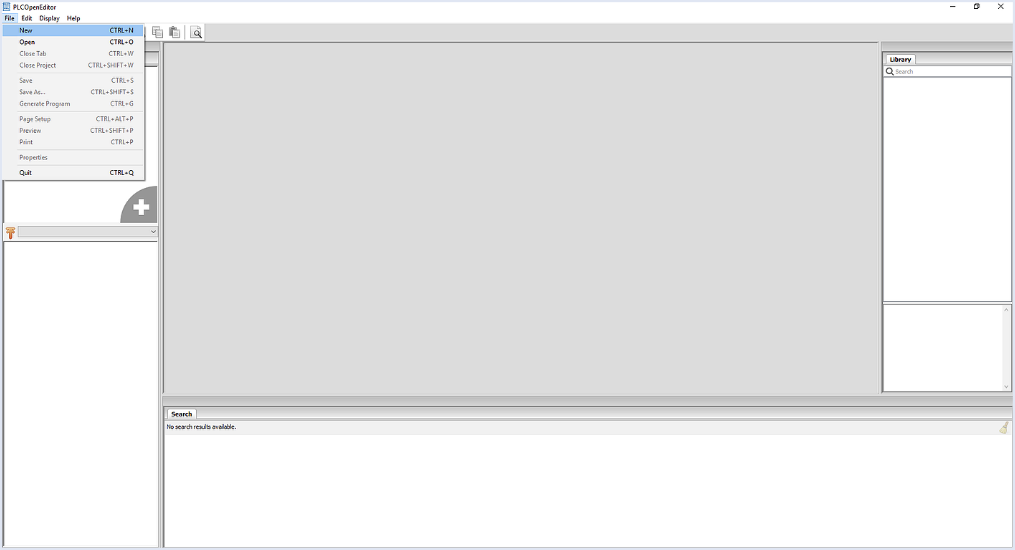

OpenPLC

OpenPLC is the open-source alternative to the big-name simulators. It supports ladder logic, structured text, and other IEC 61131-3 languages, and it runs on everything from Windows PCs to Raspberry Pi boards.

Why Yes: It’s free, open, and flexible. For students or small labs, it’s an affordable way to get into PLC programming. Plus, because it’s open-source, you can actually dig into the code if you’re curious.

Why No: It’s not meant to replace certified industrial-grade PLCs in critical systems. You won’t get the same ruggedness, timing guarantees, or official vendor support.

Best for: Proof-of-concept projects where cost is a concern, hobbyists or students.

Extra: Use OpenPLC Editor alongside Factory I/O, or deploy the runtime on a Raspberry Pi to create your own mini testbed.

How to Make Decision

We have put conditions for selection:

- WHETHER you’re tied to a vendor THEN stick with their simulator.

- WHETHER you want portability THEN CODESYS or OpenPLC.

- WHETHER you need visualization THEN add Factory I/O to the mix.

- WHETHER budget is your main concern THEN OpenPLC + Factory I/O is the cheapest effective combo.

- WHETHER you need automated testing THEN look for tools with APIs or scripting support (PLCSIM Advanced and some vendor tools offer this).

Advancement

- For students: Start with CODESYS or OpenPLC, and pair with Factory I/O if you want visuals.

- For OEM developers: Use vendor IDEs or CODESYS, simulate with virtual controllers, and integrate Factory I/O for testing.

- For commissioning teams: Stick with vendor-grade simulators like PLCSIM Advanced or Rockwell Emulate for the most accurate results.

Conclusion

IT DOESN’T exist a single best PLC simulator, it really depends on your goals, your hardware, and your budget.

Generally, incorporating a vendor-specific tool (for accuracy) with something visual or open-source (for learning and portability) gives you the best of both worlds.

Simulation isn’t just about saving time; it’s about building confidence in your code before it ever touches a real machine.

Start small, validate early, and let the simulator do the heavy lifting before the plant floor does.

Last but not least, if you ask me personally “ The Best PLC Simulation Software in 2025

” my answer would be CODESYS.

FAQ: Best PLC Simulation Software

What are the top PLC simulation/emulation tools in 2025?

Siemens TIA Portal (PLCSIM/PLCSIM Advanced), CODESYS (with simulation/runtime), Beckhoff TwinCAT (PC-based simulation), Factory I/O, OpenPLC