Imagine a factory floor. It has many different machines. It has robots, sensors, and controllers.

These machines are from different manufacturers. They use different communication protocols.

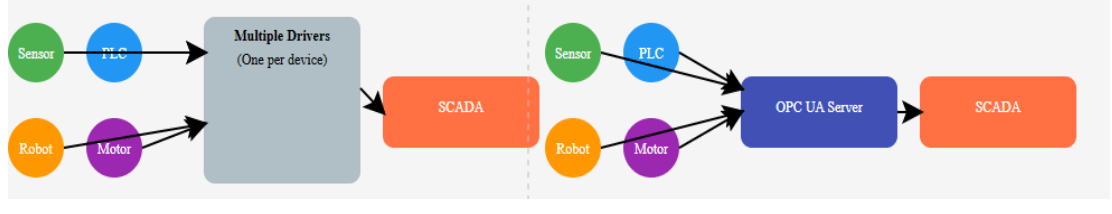

A central computer, a SCADA system, needs to collect data from them all. In the past, this was very difficult.

Each connection needed a special driver or software. It was like a room full of people speaking different languages.

No one could understand each other without a human translator. The OPC Foundation created OPC Classic to fix this problem. It provided a standard way for a computer to talk to all machines.

But it relied on Microsoft technology. This made it fragile and insecure. It could not work with other operating systems.

It also struggled to handle complex data. The need for a better solution led to OPC UA.

This article will explain what OPC UA is, how it works, why it is powerful, its role in modern industrial automation, and its benefits and limitations.

What is OPC UA?

OPC UA stands for Open Platform Communications Unified Architecture. It is a standard designed to facilitate the exchange of industrial data in a reliable, secure, and platform-independent manner.

In simple terms, OPC UA allows machines, controllers, sensors, and software applications to talk to each other without worrying about compatibility issues.

Whether a device is from Siemens, ABB, Rockwell, or another manufacturer, OPC UA provides a universal “language” for communication.

Unlike OPC Classic, OPC UA is not tied to a single vendor or operating system. It can run on Windows, Linux, and even embedded systems such as microcontrollers.

It supports modern security features and can handle complex data structures, making it suitable for the Industrial Internet of Things (IIoT) and Industry 4.0 applications.

The OPC UA Server

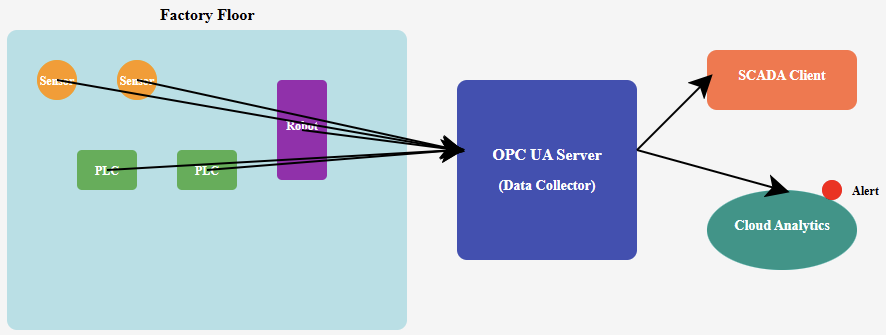

An OPC UA server is a software application that provides data from industrial devices to other systems.

Think of the server as a translator or an information hub. The server collects information from the devices it is connected to and presents it in a standardized format.

This ensures that any OPC UA client can access the data without needing to know the specifics of each device.

For example, a temperature sensor from one manufacturer and a flow meter from another can both be read by the same client software without custom coding.

Servers can run on industrial computers, PLCs, or even embedded gateways. They serve as the backbone of OPC UA communication, ensuring that data is organized, accessible, and secure.

The OPC UA Client

An OPC UA client is software that requests and consumes data provided by the server. This could be a SCADA system, HMI, historian, or cloud-based analytics platform.

The client connects to an OPC UA server and requests the information it needs. Because the data is standardized, the client does not need to understand the technical details of each device.

This separation of roles—server providing data and client consuming it—makes the system more flexible and easier to maintain.

Clients can also subscribe to real-time updates from the server, receiving notifications whenever a value changes. This allows for efficient monitoring and quick decision-making.

How OPC UA Works: A Simple Model

To make OPC UA easy to understand, consider it as a well-organized library:

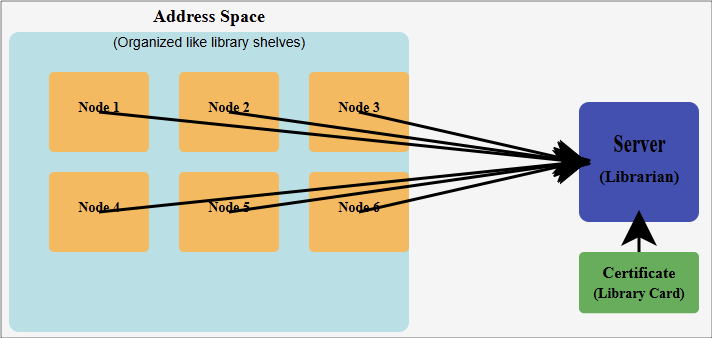

The library (Address Space)

The server organizes all its data in a hierarchical structure called the Address Space.

Think of it like a library with shelves, folders, and files. Each client can browse this structure to find exactly what it needs.

The Books (Nodes)

Each piece of information is called a Node. Nodes can represent sensor readings, motor statuses, or even programs. Every node has a unique address, making it easy to locate and reference.

The Librarian (Server)

The server is like a librarian. When a client requests information, the server finds the data and delivers it in a standardized format.

The Library Card (Certificate)

Security is important. Before a client can access the server, it needs permission, similar to a library card.

Digital certificates verify the identity of both the client and the server, ensuring secure communication.

This model makes it easy to see why OPC UA is both powerful and user-friendly.

Why OPC UA is So Powerful

OPC UA offers several advantages over older communication standards:

Platform Independence

OPC UA works on Windows, Linux, and embedded devices. It is not limited to Microsoft technologies, which allows for greater flexibility in industrial environments.

Built-in Security

Unlike OPC Classic, where security was an afterthought, OPC UA includes encryption, authentication, and user access control from the ground up. This protects industrial systems from cyberattacks.

Information Modeling

OPC UA doesn’t just send raw numbers. It provides contextual information, making the data meaningful.

For instance, instead of sending “25.5,” it can send “Temperature: 25.5°C,” along with units, location, and timestamp.

Extensibility

OPC UA is designed to be future-proof. New features can be added without breaking existing systems, supporting innovation and long-term usability.

Dual Communication Models

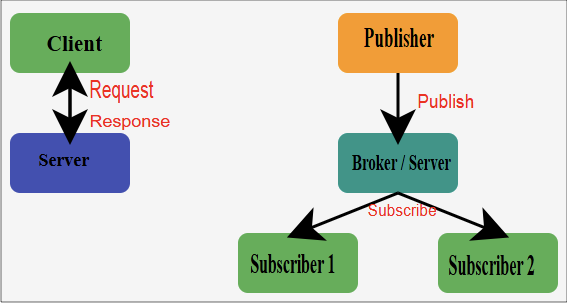

Client/Server

The traditional request-response model. The client asks for data, and the server responds.

Publish/Subscribe

A more efficient model for many-to-many communication. Devices can publish their data, and multiple clients can subscribe to receive it. This reduces network load and improves responsiveness.

OPC UA and Industry 4.0

Industry 4.0 is the concept of smart, interconnected factories. It envisions a world where machines, systems, and humans work together seamlessly to optimize manufacturing processes. OPC UA plays a crucial role in making this possible.

Traditionally, factories used the “automation pyramid,” a rigid hierarchy where lower-level devices communicated only with their immediate supervisors.

OPC UA breaks this pyramid. It enables direct, secure communication across all levels, from sensors and actuators to cloud-based analytics.

Some applications enabled by OPC UA include:

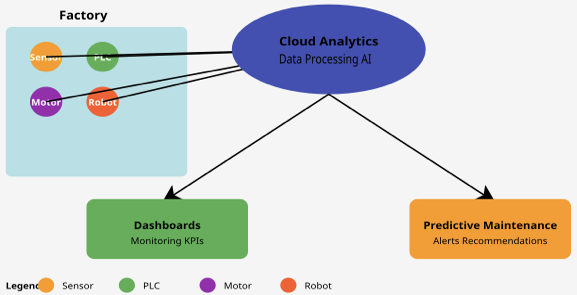

Predictive Maintenance

Machines can report their own health status. Advanced analytics can predict failures before they occur, reducing downtime and maintenance costs.

Remote Monitoring

Engineers can monitor machines from anywhere in the world, improving operational flexibility and response times.

Cloud Integration

Factory data can be sent to cloud platforms for advanced analytics, optimization, and AI-based decision-making.

Asset Management

OPC UA allows for automatic tracking of devices and systems, making inventory and maintenance management simpler and more accurate.

Real-World Example

Consider a factory that produces automotive parts. Sensors monitor temperature, pressure, and vibration on critical machines. PLCs control conveyor belts and robotic arms.

With OPC UA, a single SCADA system can monitor all devices in real time. If a vibration sensor detects an abnormal condition, the system can automatically notify maintenance personnel, adjust machine operation, or log data for later analysis.

Without OPC UA, this would require multiple software drivers, custom scripts, and possibly manual intervention. With OPC UA, the process is streamlined, secure, and standardized.

Conclusion: The Future of Industrial Communication

OPC UA has transformed industrial communication. It replaced fragmented, insecure systems with a universal, standardized framework.

It is secure, flexible, and scalable making it ideal for IIoT and Industry 4.0 applications.

Its layered architecture ensures that it can evolve with technology. New devices, data types, and communication models can be integrated without breaking existing systems.

OPC UA allows factories to become smarter, more efficient, and more resilient.

For any organization looking to modernize its industrial operations, OPC UA is no longer optional—it is a key enabler of digital transformation.

FAQ:OPC UA Explained

Can OPC UA run on embedded devices?

Yes, it can run on small controllers, microcontrollers, and even IoT gateways.

How secure is OPC UA?

Security is built into its core, including encryption, authentication, and certificate-based access control.

What is the difference between OPC Classic and OPC UA?

OPC UA is platform-independent, secure, and capable of handling complex data. OPC Classic is Windows-based, less secure, and limited in flexibility.

Does OPC UA support real-time communication?

It supports near real-time communication using the Publish/Subscribe model, which is suitable for many industrial applications.

Can OPC UA integrate with cloud platforms?

Yes, OPC UA can send data to cloud analytics platforms for AI, predictive maintenance, and advanced monitoring.