Hazardous environments containing flammable substances are always present where industrial facilities operate. Serious ignition risks are presented by electrical equipment installed in these areas.

Even small electrical sparks may ignite either combustible dust, vapors, or gases. To reduce these dangers, specialized protection methods are required. Intrinsic safety is one widely accepted explosion protection technique.

This method focuses on limiting energy rather than containing explosions. Intrinsic safety barriers play a crucial role in this approach. They restrict electrical energy before it reaches hazardous locations.

These devices allow safe operation of instrumentation systems. Industries worldwide rely on intrinsic safety barriers. Understanding their function improves system reliability and safety.

This article reviews intrinsic safety barriers, their principles, and types. It also explains their applications, standards, and finally, practical considerations.

Concept of Intrinsic Safety

Preventing ignition under all conditions is the main idea behind intrinsic safety. The principle ensures energy levels remain below ignition thresholds. Both electrical and thermal energies are carefully limited.

This limitation applies during normal operation and fault conditions. Possible faults include short circuits and component failures. Intrinsic safety differs from explosion-proof protection methods.

Instead of containing explosions, it prevents them entirely. This approach significantly improves operational safety.

Maintenance activities can occur without shutting down processes. As a result, intrinsic safety improves both safety and productivity.

What Is an Intrinsic Safety Barrier?

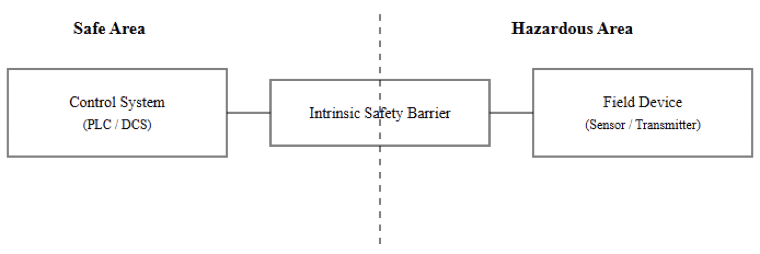

An intrinsic safety barrier is a protective interface device. It is installed between safe and hazardous areas.

The barrier controls energy entering dangerous locations. Voltage and current are limited to safe values. This prevents sparks and excessive heating.

Field instruments remain protected during faults. Intrinsic safety barriers are certified safety components.

They must meet strict international standards. Proper selection and installation are essential, and incorrect use may compromise system safety.

Purpose of Intrinsic Safety Barriers

It just needs a minimum amount of energy to ignite hazardous atmospheres. Electrical circuits naturally produce sparks and heat.

Without protection, these sources pose serious risks. Intrinsic safety barriers eliminate this ignition potential.

They restrict energy during both normal and abnormal conditions. Personnel safety is significantly enhanced.

Equipment damage is also greatly reduced. Regulatory authorities require such protection methods.

Barriers simplify compliance with safety regulations. They provide a reliable and proven safety solution.

Operating Principle of Intrinsic Safety Barriers

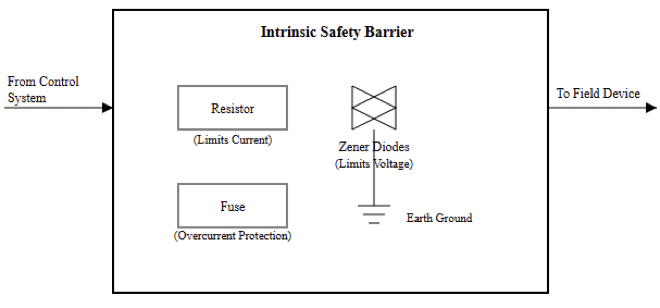

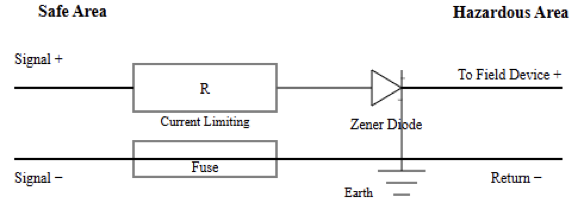

Intrinsic safety barriers operate by controlling electrical energy. They limit voltage, current, and stored energy.

This is achieved using specific protective components. Resistors restrict excessive current flow. Zener diodes clamp voltage to safe limits.

Fuses disconnect circuits during severe faults. These components work together continuously.

Energy entering hazardous areas remains non-incendive. The operating principle is simple but effective.

Internal Components and Construction

Intrinsic safety barriers contain carefully selected components. Resistors are used for current limitation.

Zener diodes provide voltage clamping protection. Fuses offer final fault protection. Ground terminals ensure proper voltage reference.

Protective enclosures shield internal components. Each component must be safety certified.

Long-term reliability can be improved by high-quality construction. Component failure can compromise intrinsic safety. Therefore, strict manufacturing standards are applied.

Types of Intrinsic Safety Barriers

Intrinsic safety barriers are available in different types. The two primary categories are passive and active barriers.

Passive barriers are commonly called Zener barriers. Active barriers are known as galvanic isolators. Each type serves specific application needs.

Selection depends on system design and requirements. Understanding their differences is essential.

Incorrect selection may introduce safety risks. Engineers must evaluate each application carefully.

Zener Barriers

Zener barriers are passive intrinsic safety devices. They rely on resistors and Zener diodes. Excess voltage is diverted to a safety ground. This grounding path is essential for protection.

Zener barriers are simple to use and financially efficient. They are widely used in many installations.

However, grounding integrity is critical. Poor grounding reduces their effectiveness. Regular grounding inspections are required.

Galvanic Isolators

Galvanic isolators are active intrinsic safety barriers. They use transformers or opto-isolators internally.

There is no direct electrical connection between zones. This provides inherent electrical isolation. Grounding requirements are less restrictive.

Signal accuracy is usually better. Noise interference is significantly reduced. Galvanic isolators are more expensive. Their advantages often justify the higher cost.

Comparison Between Barrier Types

Zener barriers require a high-integrity safety ground. Galvanic isolators operate without such grounding.

Isolators provide superior signal quality. Zener barriers offer simpler installation and lower cost.

System complexity influences the selection decision. Both barrier types meet intrinsic safety standards. Proper evaluation ensures safe and reliable operation.

Hazardous Area Classification

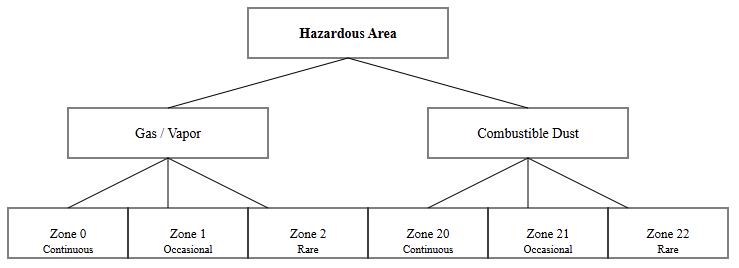

Special standards are used to classify hazardous areas. These classifications define ignition risk levels.

Zone Zero represents continuous hazardous presence. Zone One indicates occasional hazardous conditions.

Zone Two represents rare hazardous occurrences. Barriers must be rated for the specific zone.

Incorrect classification leads to unsafe installations. Compliance with standards is mandatory.

Gas Groups and Temperature Classes

Different gases ignite at different energy levels. Gas groups categorize explosion severity. Temperature classes limit maximum surface temperatures. Equipment must remain below these limits.

Intrinsic safety barriers must match gas group ratings. Temperature compliance prevents hot surface ignition.

Incorrect ratings may cause dangerous conditions. Standards clearly define these requirements.

Standards and Certification Requirements

Intrinsic safety systems follow international standards. IEC 60079 governs intrinsic safety worldwide. ATEX directives apply within European regions. North America uses NEC and NFPA standards.

Certification ensures equipment meets safety requirements. Documentation must match installed components. Inspectors verify compliance during audits. Certified systems reduce legal and operational risks.

Typical Applications

Intrinsic safety barriers are used across industries. Oil and gas facilities rely on them heavily.

Chemical plants use intrinsic safety instrumentation. Pharmaceutical production requires precise, safe measurements.

Mining operations face explosive dust hazards. Water treatment facilities also apply intrinsic safety.

These applications demand reliable protection. Barriers provide proven safety performance.

Installation Considerations

Correct installation is critical for intrinsic safety. Barriers must be installed in safe areas. Wiring practices must follow approved standards. Cable segregation prevents unintended energy transfer.

Grounding must meet manufacturer specifications. Labels help identify intrinsically safe circuits.

Poor installation compromises system safety. Strictly following the installation guidelines helps to solve this situation.

Maintenance and Inspection

Routine inspection is always required in intrinsic safety systems. Connections must remain secure and undamaged.

Ground resistance should be checked regularly. Damaged components must be replaced immediately.

System modifications require documentation updates. Regular maintenance preserves certification validity. Neglect increases safety risks significantly.

Advantages of Intrinsic Safety Barriers

Intrinsic safety barriers provide reliable explosion prevention. Maintenance can occur without shutting down processes. Installation costs are often lower. System flexibility is improved significantly.

Explosion-proof enclosures become unnecessary. Operational uptime increases. Safety performance remains consistently high.

Limitations of Intrinsic Safety

Intrinsic safety limits available electrical power. High-power devices cannot use this method. Cable parameters must be carefully calculated.

System design requires engineering expertise. Incorrect calculations reduce safety margins. Despite limitations, intrinsic safety remains effective.

Key Takeaways: What Is an Intrinsic Safety Barrier?

This article demonstrated how intrinsic safety barriers prevent ignition in hazardous environments.

Intrinsic safety barriers are essential industrial safety devices. They limit energy entering hazardous environments. Proper selection ensures reliable explosion prevention.

Understanding barrier types improves system design quality. Correct installation prevents ignition risks effectively. Compliance with standards ensures legal operation.

Industries benefit from improved safety and reliability. Intrinsic safety remains a trusted protection method worldwide.

FAQ: What Is an Intrinsic Safety Barrier?

What is an intrinsic safety barrier?

A device that is used to limit energy to prevent sparks in hazardous areas.

Why is it used?

To stop electrical energy from igniting gaseous dust, vapors, or gases.

How does it work?

Uses fuses, Zener diodes, and resistors to restrict voltage and current.

Where is it installed?

In the safe area, between control systems and field devices.

Does a barrier alone make a system safe?

No, the entire loop must comply with intrinsic safety requirements.

Types of barriers?

- Zener (passive) barriers

- Galvanically isolated barriers