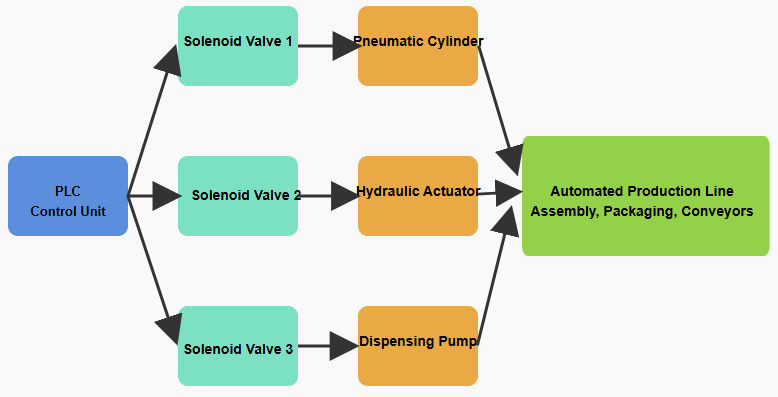

In modern automation, machines rarely operate passively, they need to move, react, and control their environment efficiently.

Whether it’s regulating the flow of liquids or gases, an essential component manages this task with precision and reliability: the solenoid valve.

What is a Solenoid Valve?

A solenoid valve is an electromechanical device designed to convert electrical signals into a mechanical action.

This action, in turn, opens or closes a valve to control the movement of fluids within a system.

Solenoid valves are indispensable in automated processes because they deliver a combination of precision, speed, and reliability that manual valves cannot match.

In this article, we will learn what a solenoid valve is, how it operates, its types, advantages, and applications.

Components of a Solenoid Valve?

A solenoid valve is essentially a combination of two key components:

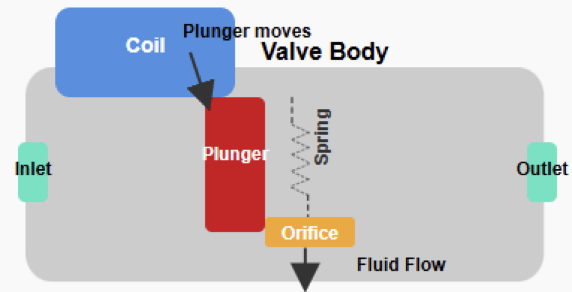

- The Solenoid: This is an electromagnet that generates a magnetic field when energized.

- The Valve Body: This houses the mechanical components responsible for opening or closing the fluid path.

The solenoid consists of a coil of wire wound around a ferromagnetic core. Within the core, a plunger or piston made of ferromagnetic material moves in response to the magnetic field.

When electricity passes through the coil, a magnetic field is generated. This magnetic field pulls the plunger, which in turn either opens or closes the valve’s orifice, regulating fluid flow.

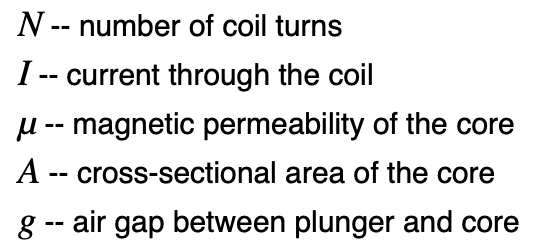

Mathematically, the magnetic force acting on the plunger can be expressed as:

Where:

This equation shows that the plunger’s movement depends on the coil current and the geometry of the magnetic circuit.

How a Solenoid Valve Works

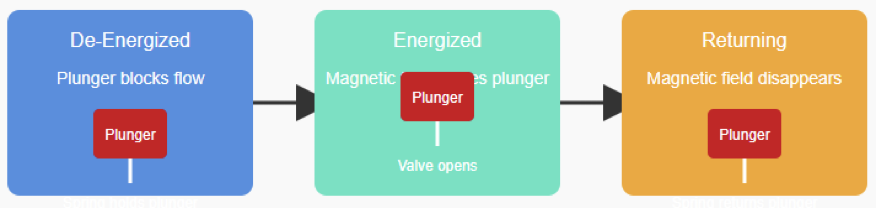

The operation of a solenoid valve is straightforward yet remarkably effective. Its functionality can be broken down into four stages:

De-energized State:

In this default state, a spring holds the plunger in position. In a normally closed (NC) valve, the plunger blocks the fluid path, preventing flow.

In a normally open (NO) valve, the plunger allows fluid to flow freely without electrical input.

Energized State:

When an electrical current flows through the solenoid coil, a magnetic field form. This field exerts a force on the plunger, moving it against the spring’s resistance.

Valve Actuation:

The plunger’s movement either opens or closes the valve’s orifice. This simple mechanical action precisely controls the fluid or gas flow.

Return to Default:

Once the electrical signal stops, the magnetic field disappears. The spring then pushes the plunger back to its original position, returning the valve to its de-energized state.

The entire process takes milliseconds, enabling high-speed and highly accurate control, crucial in modern automation systems.

Key Components of a Solenoid Valve

A solenoid valve contains multiple components working in concert:

Valve Body

The main housing of the valve, constructed from brass, stainless steel, or plastic. It contains the orifice, ports, and internal passages.

Solenoid Coil

The electromagnet generating the magnetic field to move the plunger.

Plunger (or Piston)

A movable component that opens or closes the valve. Its material is usually ferromagnetic.

Spring

Provides the restoring force to return the plunger to its default position when the coil is de-energized.

Orifice

The opening in the valve that the plunger covers or uncovers to control fluid flow.

Ports

The inlet and outlet connections for fluid or gas. The number of ports defines the valve configuration (e.g., 2-way, 3-way).

Types of Solenoid Valves in Automation

Solenoid valves come in several configurations, chosen according to specific application needs.

By Operating Principle

Direct-Acting Valves

The solenoid directly opens or closes the valve. These are simple, fast, and ideal for low pressure and low flow rate applications. No fluid pressure difference is required to operate the valve.

Pilot-Operated Valves

A small solenoid controls a pilot valve, which uses the system’s fluid pressure to operate a larger main valve. These are suited for high flow rate and high-pressure systems and are more energy-efficient.

Semi-Direct Acting Valves

This type combines features of direct and pilot-operated valves. They can operate at low or zero pressure while handling moderate-to-high flow rates.

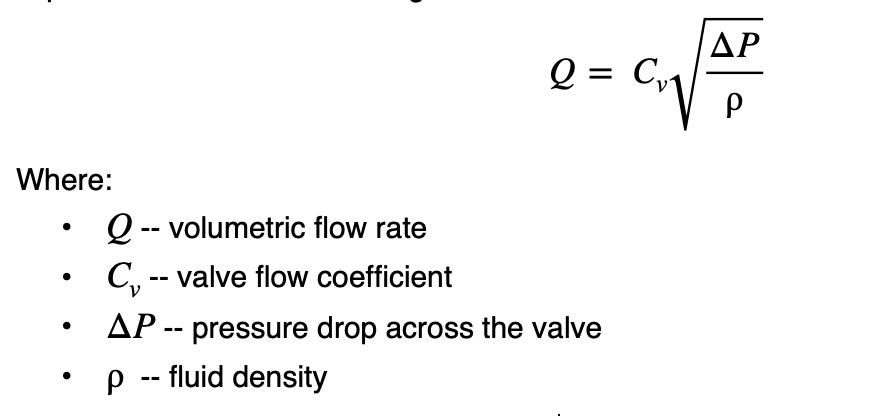

Equation for Fluid Flow Through a Solenoid Valve:

By Flow Path (Number of Ports)

2/2-Way Valves

Two ports and two positions, acting as a simple ON/OFF switch.

3/2-Way Valves

Three ports, two positions. Can direct flow to multiple paths or vent pressure, commonly used for single-acting cylinders.

4/2, 4/3, and 5/2 Valves

More complex configurations to control double-acting cylinders or sophisticated fluid paths.

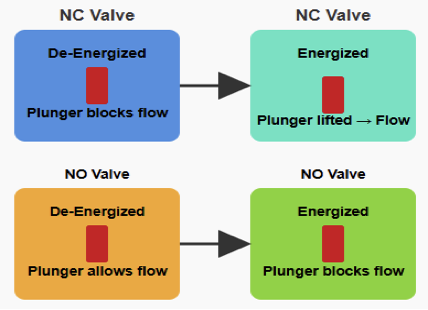

By Default State

Normally Closed (NC)

Closed when de-energized; opens when powered. Most common type.

Normally Open (NO)

Open when de-energized; closes when powered. Useful in fail-safe applications where uninterrupted flow is critical.

Advantages of Solenoid Valves in Automation

Solenoid valves bring numerous benefits to automated systems:

Fast Response Time

Switching occurs in milliseconds, essential for precise and high-speed operations.

Remote Control

Electrically actuated, allowing centralized or remote operation, ideal for inaccessible or hazardous areas.

Reliability and Durability

Few moving parts ensure a long service life, even in harsh industrial environments.

Compact Design

Small footprint allows installation in tight spaces and manifold mounting.

Low Energy Consumption

Modern solenoids are highly efficient, reducing operational costs compared to other actuators.

Automation of Fluid Control

Replaces manual valves, improving efficiency, safety, and productivity.

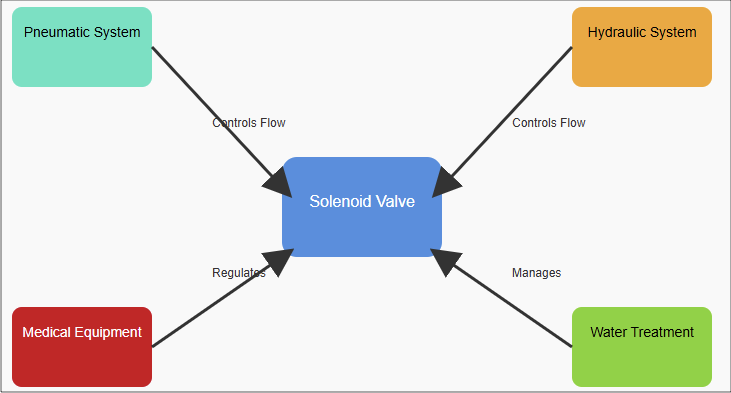

Applications of Solenoid Valves in Automation

Solenoid valves are widely used in multiple industries:

Pneumatic Systems

Control compressed air to operate actuators, cylinders, and tools.

Hydraulic Systems

Direct hydraulic fluid to control heavy machinery in manufacturing and construction.

Water Treatment

Manage water and chemical flow for precise dosing and processing.

Food and Beverage Industry

Control ingredient flow and cleaning fluids in automated dispensing and bottling systems.

Medical Equipment

Regulate gases and fluids in devices such as ventilators and dialysis machines.

Automated Sprinkler Systems

Efficient irrigation by controlling water distribution across multiple zones.

Industrial Processes

Used for mixing, dosing, and distributing fluids in pilot plants and full-scale production lines.

Key Takeaway: What is a Solenoid Valve?

In this article, we will learn what a solenoid valve is, how it operates, its types, advantages, and applications.

Along the way, diagrams and equations will help illustrate the concepts more clearly, providing both practical and theoretical insight.

The solenoid valve is a cornerstone component in automation. It creates a seamless link between electrical signals and fluid power, enabling precise and reliable control.

From simple on/off functions to complex directional control, solenoid valves are versatile, fast, and efficient.

As automation technologies evolve, the solenoid valve continues to play a critical role in industrial control systems, offering reliability, compactness, and energy efficiency.

Its simple operating principle combined with robust performance makes it indispensable for modern industrial processes.

FAQ: What is a Solenoid Valve?

What is the main difference between normally open and normally closed solenoid valves?

Normally open valves allow flow when de-energized, while normally closed valves block flow until energized.

Can solenoid valves handle high pressures?

Yes, especially pilot-operated and semi-direct acting valves designed for high-pressure systems.

How fast can a solenoid valve respond?

Many solenoid valves switch in milliseconds, suitable for high-speed automation.

Are solenoid valves suitable for hazardous environments?

Yes, especially explosion-proof or stainless-steel designs for corrosive or flammable environments.

Can they be used in both liquids and gases?

Absolutely. The design may vary slightly depending on the medium, but solenoid valves can handle air, water, oil, and other fluids.