Industrial automation uses control systems, software, and machines to perform industrial processes with little human help.

This technology has changed manufacturing and production by improving efficiency, safety, and product quality.

Automation reduces human error, increases consistency, and allows continuous operation even under demanding conditions.

It also helps industries collect real-time data for better decision making and maintenance planning.

As a result, companies can produce more with fewer resources while ensuring higher precision and reliability.

There are several types of automation systems, each with unique traits suited for specific uses.

The choice of system depends on production volume, flexibility needs, and product variation.

This article explores the main types of industrial automation systems, including their components, advantages, and limitations.

Types of Industrial Automation Systems

An automation system uses technology to perform tasks with little or no human help.

It includes devices such as sensors, controllers, and actuators. These systems combine hardware and software to control processes efficiently.

They improve quality, safety, and productivity in many industries. Examples include manufacturing, healthcare, and building management. Main benefits are lower labor needs and higher precision.

They can also perform dangerous or repetitive tasks safely. In this section, different types of automation will be briefly discussed.

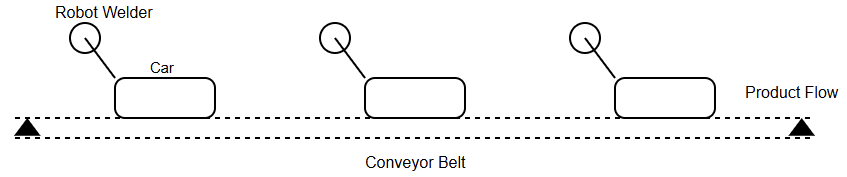

Fixed Automation (Hard Automation)

Fixed automation is designed for continuous, high volume production of identical products. Once installed, the equipment stays fixed to perform a specific set of operations.

Key Characteristics

Fixed automation uses dedicated machines built for one product or process. It operates at high speed and achieves high output. However, it has very low flexibility and is hard to modify for a new product.

The initial investment is high, but the cost per unit becomes low over time due to mass production.

Examples

In car manufacturing, conveyor belts and robotic arms repeat tasks such as welding or painting.

Chemical production lines use continuous flow systems. Food processing machines package identical products in large quantities.

Advantages

These systems achieve high productivity and consistency. The product quality remains uniform, and human error is minimal. Once installed, operating costs per unit are very low.

Limitations

They are not flexible and cannot adapt easily to product changes. The initial setup is expensive. They are economical only when used for continuous mass production.

The following figure shows a diagram illustrating a fixed automation assembly line for car manufacturing, showing a conveyor belt and fixed-position robotic welders.

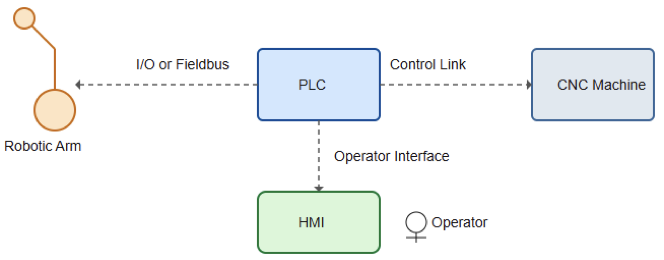

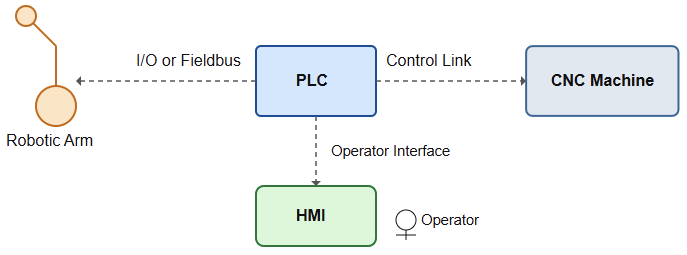

Programmable Automation

Programmable automation provides more flexibility than fixed systems. It suits batch production where the product design changes occasionally. Machines are controlled by programs that can be modified for different operations.

Key Characteristics

The machines can be reprogrammed to make new products. It is ideal for batch production where product types vary over time.

It offers moderate flexibility, though reprogramming takes time. The initial cost is usually lower than fixed automation.

Components

It includes PLCs to control processes, industrial robots for various tasks, and CNC machines for machining operations.

It also uses programming devices to load control programs and HMIs for operator control and monitoring.

Examples

Electronics plants use programmable systems to produce different components in batches.

CNC machines make custom parts in small quantities. Batch chemical reactors can be programmed for various recipes.

Advantages

Programmable systems are versatile and cost effective for medium volume production. They offer better control over processes.

Limitations

Reprogramming causes downtime and reduces speed compared to fixed systems. Skilled operators are needed for programming and troubleshooting.

The next figure indicates a diagram showing a programmable system with a PLC connected to a robotic arm and a CNC machine, plus an HMI for operator control.

Flexible Automation (Soft Automation)

Flexible automation extends the adaptability of programmable systems. It allows automatic changeovers between products with little or no downtime.

Key Characteristics

It can handle many product variations and switch tasks automatically. Changeovers are controlled by software, using sensors and vision systems. It is ideal for low volume, high mix production environments.

Components

It includes robotic arms capable of multiple tasks, vision and sensor systems to detect product differences, software based control for reconfiguration, and automated tool changers for switching equipment.

Examples

Automotive plants use flexible automation to produce cars with different engines or colors on the same line.

Electronics factories assemble various circuit boards. Medical device manufacturers test and sort multiple product types.

Advantages

It gives maximum agility and fast response to market changes. Automated changeovers reduce downtime and improve productivity in mixed production.

Limitations

The systems are expensive to install and complex to maintain. They need skilled personnel. For a single repetitive product, they may be slower than fixed systems.

The figure below exhibits a diagram showing a flexible automation cell with a robotic arm, an automated tool changer, and a vision system identifying different products.

Integrated Automation

Integrated automation links all systems and machines across a plant into one network. It automates the entire process, not just individual parts.

Key Characteristics

It requires minimal human input. A central computer or MES system manages all operations.

Data is shared in real-time with other systems, including business software. It often uses AI, IoT, and advanced robotics.

Components

It includes CAD/CAM for smooth design-to-production flow, MES for scheduling and resource management, and ERP for handling finance and logistics.

Automated material handling systems move products, while IoT sensors collect data for monitoring.

Examples

Lights out factories operate with no human presence. Pharmaceutical plants use integrated systems to control the full production cycle. Modern automotive plants use one system to manage the entire process.

Advantages

It offers maximum efficiency and quality control. AI and sensors maintain precision and detect issues early.

Data helps make better decisions and predict maintenance needs. It also allows product changes through software updates.

Limitations

Integrated systems have very high installation and software costs. They need expert staff for setup, operation, and cybersecurity. Increased connectivity can raise the risk of cyberattacks.

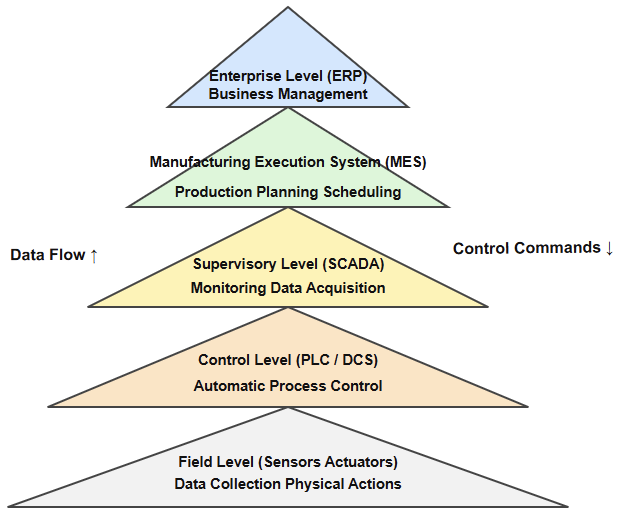

The Automation Pyramid, showing system levels from sensors and actuators at the base to ERP at the top is indicated in the next figure.

Key Takeaways: Types of Industrial Automation Systems

This article presented the main types of industrial automation systems and explained how each one functions, including their components, advantages, and limitations.

It showed that there are different types of industrial automation systems. From fixed systems for large-scale production to flexible and integrated systems for complex operations. The right system depends on production needs, volume, and budget.

Future automation will be smarter, more adaptable, and more connected. Embracing these technologies will increase productivity and innovation, helping companies remain competitive.

Industrial automation continues to grow as technology evolves. Several trends are shaping its future.

Artificial Intelligence and Machine Learning will enhance predictive maintenance and improve quality.

Collaborative robots (cobots) will safely work with humans. IoT and 5G will connect devices for real-time data sharing.

Digital twins will simulate production systems for optimization. Automation-as-a-Service (AaaS) will make advanced systems more affordable.

FAQ: Types of Industrial Automation Systems

What are the main types of industrial automation?

The main types are fixed automation, programmable automation, flexible automation, and integrated automation (or computerized / networked systems).

When is fixed automation used?

Fixed automation is ideal for very high-volume, continuous production of identical products. It’s efficient but inflexible.

What is programmable automation good for?

It works well in batch production environments. Machines can be reprogrammed to handle different products or tasks.

How does flexible automation differ?

Flexible automation supports automatic changeovers between different products with minimal downtime. It’s suited for “high mix, low volume.”

What is integrated automation?

Integrated automation links all systems and machines in a facility,from sensors, controllers, robots, up to enterprise systems (ERP). It enables full automation and data flow.

What are the trade-offs across these types?

Fixed systems are fast and low cost per unit but very inflexible.

- Programmable systems add flexibility but incur downtime for reprogramming.

- Flexible systems reduce changeover time but are complex and costly.

- Integrated systems offer full optimization and control but require high investment and strong IT/engineering support.

How do I choose the right type?

Choose based on production volume, product variety, required flexibility, budget, and future growth plans.