Differential Pressure Transmitters, also known as DP transmitters, are among the most widely used instruments in industrial measurement and control systems.

They play a critical role in monitoring flow, level, pressure, and filter condition across numerous industries.

These industries include power generation, water treatment, and oil and gas. In addition, pharmaceuticals and manufacturing are also incorporated.

By measuring the difference between two pressure points, differential pressure transmitters provide indirect measurements.

These measurements are highly reliable and represent key process variables. Their robustness and accuracy make them essential components in modern automation systems. Also, their versatility is characteristic.

Understanding their operating principles and construction is vital for engineers. Understanding their applications and limitations is also essential.

This article addresses operating principles and construction in detail. It also covers measurement methods, applications, selection criteria, and practical considerations.

DP Transmitter

A differential pressure transmitter is an instrument that measures pressure difference. This difference exists between the two applied pressures. The pressures are applied to high-pressure and low-pressure ports.

Instead of measuring absolute pressure at one point, the transmitter compares two values. It then outputs a standardized signal. This signal is proportional to the measured difference.

The output signal is standardized for industrial control systems. Most transmitters provide a 4–20 mA analog current signal. Some models instead provide a 0–10 V analog voltage output.

Modern smart transmitters also support digital communication protocols. PROFIBUS, Modbus, Foundation Fieldbus, and HART are examples of these protocols. The measured differential pressure is often used indirectly. It is used to infer the flow rate.

It is also used to determine the liquid level. Filter condition can also be monitored this way. This versatility makes differential pressure transmitters widely applied instruments.

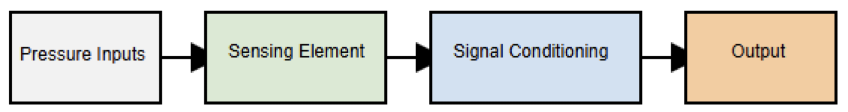

Basic Operating Principle

The operating principle of a differential pressure transmitter is based on pressure comparison. It measures the pressure difference between two points. This difference is expressed as

P₁ represents pressure at the high-pressure side. P₂ represents pressure at the low-pressure side. This pressure difference causes mechanical deformation.

The deformation occurs in the sensing element. The amount of deformation depends on the pressure magnitude.

This mechanical movement is converted into an electrical signal. The signal is amplified and conditioned.

It is then transmitted to the control system. This principle is widely applied in industrial processes.

In flow measurement, pressure is measured before and after a restriction. In level measurement, vessel pressures are compared vertically.

In filter monitoring, pressure is measured upstream and downstream. These comparisons allow detection of clogging or process changes.

Main Components

A typical differential pressure transmitter consists of several essential components. These components work together to ensure accurate measurement.

The pressure ports provide physical process connections. One port is assigned as high-pressure.

The other port is assigned as low-pressure. The difference between these pressures is measured.

The sensing element reacts mechanically to differential pressure. Common sensing elements include diaphragms and bellows.

Flexible membranes are also widely used. The element deflects proportionally once pressure is applied.

Mechanical deformation is converted into an electrical signal by the sensor. This conversion depends on transmitter design.

Technologies include strain gauges and capacitive sensors. Piezoresistive and resonant sensors are also used.

The signal conditioning circuit processes the raw sensor signal. It amplifies low-level signals. It also linearizes the output.

Temperature compensation is applied to improve accuracy. The output and communication interface deliver the processed signal. This signal is sent to external systems. Outputs may be analog, digital, or combined.

Types of DP Transmitters

Differential pressure transmitters are categorized by sensing technology. They are also categorized by intended application.

Diaphragm-based transmitters use flexible diaphragms. These diaphragms deflect under a pressure difference.

They offer high accuracy and excellent stability. They are suitable for low to medium pressure ranges.

Capacitive differential pressure transmitters detect capacitance changes. These changes occur due to diaphragm movement.

They are well-suited for very low pressures. High sensitivity makes them ideal for cleanrooms and low-flow applications.

Piezoresistive transmitters use strain-sensitive resistors. These resistors are bonded to a diaphragm.

Pressure-induced deformation changes electrical resistance. These transmitters are common in medium to high-pressure applications. Resonant sensor transmitters measure vibration frequency changes.

These changes result from pressure-induced stress. They offer exceptional accuracy and long-term stability. However, they are generally more expensive.

Differential Pressure Measurement Methods

Differential pressure transmitters are widely used for indirect measurement. They rely on established physical relationships. These relationships link pressure difference to other variables.

Flow Measurement Using Differential Pressure

Flow measurement is a common application of differential pressure transmitters. A restriction is placed in the flow path. This restriction causes a pressure drop. The pressure drop is related to the flow rate.

The transmitter measures this differential pressure. Common primary flow elements include orifice plates.

Venturi tubes and flow nozzles are also used. Pitot tubes are applied in some cases. Here, the mathematical equation is based on the relationship between flow and pressure.

This is how they relate: Flow rate is proportional to the square root of differential pressure. Accurate calibration is therefore essential.

Level Measurement Using Differential Pressure

Liquid level measurement using differential pressure is widely applied. It is used in both open and closed tanks.

The pressure exerted by a liquid column depends on height. It also depends on liquid density.

In open tanks, the high-pressure side connects to the bottom. The low-pressure side is vented to the atmosphere.

In closed tanks, the low-pressure side connects to the vapor space. In both cases, the measured differential pressure corresponds to the liquid level.

Filter and Pump Monitoring

Differential pressure transmitters are commonly used for equipment monitoring. Filters, pumps, and heat exchangers are typical examples. As a filter becomes clogged, the pressure drop increases.

Continuous monitoring reveals this change. Abnormal pressure differentials can indicate problems.

These problems include cavitation and fouling. Mechanical issues can also be detected early.

Installation Considerations

Correct installation is essential for accurate measurement. Poor installation can introduce significant errors.

Pressure tapping points must be carefully selected. Technicians must make sure they avoid areas of turbulence.

Air entrapment and sediment buildup must also be prevented. In flow measurement, standardized tapping locations are often used.

Impulse lines should be equal in length. They must be properly sloped. This prevents trapped gas or liquid columns.

Such conditions can cause measurement errors. Mounting position can affect the zero offset.

Hydrostatic head may influence readings. Zero calibration is often performed after installation.

This compensates for mounting effects. Environmental conditions must also be considered. These include temperature extremes and vibration. Moisture and affect reliability.

Maintenance and Calibration

Calibration ensures measurement accuracy across the operating range. Known differential pressures are applied during calibration. Zero, span, and linearity are adjusted accordingly.

Calibration is commonly performed using pressure calibrators. Deadweight testers are also used.

Smart transmitters support digital calibration. Verification can be done without removing the device.

Routine maintenance includes impulse line inspection. Blockage and leakage must be checked. Seals and diaphragms are inspected regularly.

Output signals should be verified. Due to devices’ connectivity capability, remote diagnostics are now possible. The main advantage of these is the reduction of downtime and costs.

Advantages and Disadvantages

The DP transmitters offer a vast range of advantages, such as high accuracy and repeatability.

They are suitable for critical process measurements. Their versatility allows use across multiple applications. Flow, level, and pressure monitoring are all possible.

The technology is well established and standardized. It is compatible with PLC and DCS systems.

These transmitters operate reliably in harsh environments. However, certain limitations exist.

Measurements are often indirect. Accuracy depends on fluid density and temperature. Impulse lines may clog, freeze, or leak. Flow accuracy decreases at low rates. Proper design and maintenance are essential.

Applications Across Industries

Differential pressure transmitters are used in many industries.

- Oil and gas: they measure flow and separator levels. They are also used for pipeline monitoring.

- Power plants: They measure steam flow. They also control the boiler drum level.

- Water and wastewater systems: They monitor filters and are used for flow measurement.

- Pharmaceuticals: They control cleanroom pressure. They also support sterile processes.

- HVAC systems: They measure airflow. They also balance room pressure.

Selection Criteria

When specifying a transmitter, several factors must be considered. Material compatibility is critical. Wetted parts must suit the process medium.

Although 316L stainless steel is the industry benchmark, extreme corrosive applications may mandate the integration of Tantalum, Monel, or Hastelloy.

Turn-down ratio is another important factor. It defines the usable measurement range. Accuracy must be maintained across this range. Modern transmitters achieve turndowns up to 100:1.

Digital communication is increasingly important. Protocols such as HART 7 and Modbus are common.

WirelessHART supports predictive maintenance and integration. Multivariable transmitters provide additional benefits.

They measure differential pressure and static pressure. They also measure process temperature.

This enables compensated mass flow measurement. Instrumentation complexity is reduced.

Key Takeaways: Differential Pressure Transmitters

This article details the fundamentals of differential pressure transmitters. It covered operating principles and key components. Measurement methods and installation practices were explained.

Advantages, limitations, and applications were discussed. Differential pressure transmitters remain fundamental instruments. They support industrial measurement and control systems.

By measuring pressure difference, they determine flow and level. They also monitor equipment condition.

Their proven operating principle ensures reliability. Robust construction supports harsh environments.

Compatibility with modern automation ensures continued relevance. Proper selection and maintenance ensure long-term performance. Understanding these instruments is essential for process professionals.

FAQ: Differential Pressure Transmitters

What is a differential pressure transmitter?

It measures the pressure difference between two points and outputs a proportional signal.

How does it work?

A sensing element detects a pressure difference and converts it into an electrical signal.

What outputs are common?

4–20 mA analog; some support digital protocols like HART or Modbus.

Can it measure any fluid?

Depends on the wetted material; corrosive fluids may need special alloys.

Why is calibration important?

Ensures accurate readings and compensates for sensor drift.

What causes inaccurate readings?

Blocked impulse lines, poor installation, power issues, or sensor damage.

How often should it be maintained?

Depends on the process; inspect lines, connections, and signals regularly.

Typical applications?

Flow, level, filter monitoring, pump performance, and process control.

Can it measure static or absolute pressure?

Standard DP transmitters measure only differential pressure; multivariable units can also measure static pressure or temperature.

How does installation affect accuracy?

Proper location, routing, and impulse line setup are critical for reliable readings.