Programmable Logic Controllers (PLCs) are durable, purpose-built computers. They are designed to automate industrial processes.

PLCs are known for their reliability, adaptability, and ability to function under harsh conditions.

They were initially developed to replace hard-wired relay control systems in the automotive industry. Today, PLCs form the foundation of automated systems across various sectors.

What are the Top 10 PLC Controller Manufacturers?

These sectors include manufacturing, energy, and water treatment. The global PLC landscape is shaped by a select group of leading manufacturers. These companies provide diverse product ranges and cutting-edge technologies.

They continuously innovate, driving progress. They also help define the future of industrial automation.

This article explores the top PLC manufacturers. It examines their product ecosystems and the industries they serve.

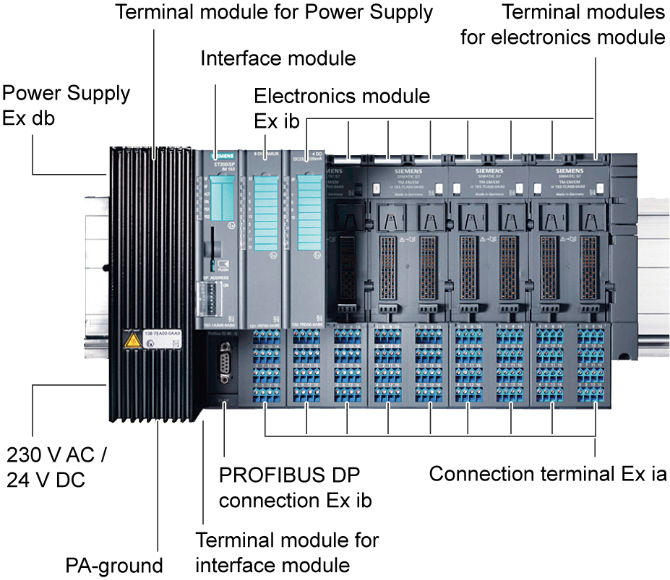

Siemens AG

Siemens is widely regarded as a global leader in industrial automation and digitalization.

Its flagship PLC platform, the SIMATIC series, is recognized for flexibility, integration, and robustness.

These controllers perform well in demanding environments. Siemens combines its hardware with the Totally Integrated Automation (TIA) Portal. This is a comprehensive engineering framework.

It unifies programming, monitoring, and diagnostics in a single environment. This approach greatly simplifies system design. It also reduces commissioning time.

The modular structure of Siemens PLCs allows users to expand systems effortlessly.

Engineers can add I/O modules or communication cards as needed. The company also offers high-availability and redundant configurations for critical infrastructure applications.

These configurations ensure continuous operation even in the event of hardware failure.

Siemens PLCs are prevalent in automotive assembly lines, food and beverage production, and energy generation facilities.

Their scalability—from compact controllers like the S7-1200 to high-end systems like the S7-1500—makes them suitable for both small machines and complex process plants.

Rockwell Automation (Allen-Bradley)

Rockwell Automation operates under the Allen-Bradley brand. It is a major force in the automation sector.

It is particularly strong in North America. Its ControlLogix series is tailored for large and complex systems.

The CompactLogix range caters to medium-sized operations. These operations still require high performance and reliability. Rockwell’s Studio 5000 software provides a unified development environment.

It integrates control, visualization, and motion configuration in one platform. One of the standout advantages of Allen-Bradley PLCs is their superior communication capability. They support multiple industrial protocols such as EtherNet/IP and DeviceNet.

This enables seamless integration with Rockwell’s drives, sensors, and HMIs. Built-in safety and cybersecurity features enhance protection in connected systems. These features align with modern industrial cybersecurity standards.

Allen-Bradley PLCs are widely used in discrete manufacturing, material handling, and logistics automation.

Industries value their consistent performance. They also appreciate the ease of integration with enterprise level systems for data exchange and remote diagnostics.

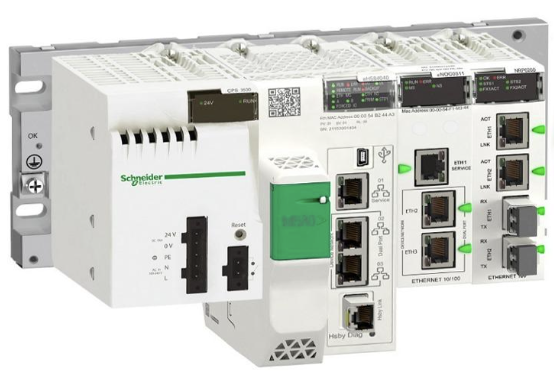

Schneider Electric SE

Schneider Electric is a global innovator in energy management and industrial automation.

Its Modicon PLC family, particularly the Modicon M580 ePAC, represents a new generation of connected controllers.

These controllers are built for the Industrial Internet of Things (IIoT). The platform supports advanced Ethernet communication.

It also meets modern cybersecurity standards. Remote monitoring capabilities are fully supported.

The EcoStruxure Machine Expert software simplifies the design and configuration of automation systems.

It provides a consistent engineering experience across various Schneider hardware platforms.

Schneider PLCs are known for reliability and scalability. They are widely deployed in utilities, water treatment, HVAC systems, and manufacturing environments. These environments require robust operation under harsh conditions.

In addition to performance, Schneider places strong emphasis on sustainability and energy efficiency.

Their PLCs are designed to optimize energy use. They integrate seamlessly into larger smart-grid and energy-management ecosystems.

Mitsubishi Electric Corporation

Mitsubishi Electric has long been a leader in factory automation and control systems. Its MELSEC PLC family covers a wide range of industrial requirements. The MELSEC-F series is compact and ideal for small-scale machines.

The MELSEC-L and MELSEC-Q series are flexible and modular. They are designed for large-scale automation projects.

The GX Works3 software environment allows engineers to program, simulate, and troubleshoot efficiently. This improves productivity and reduces errors.

Mitsubishi PLCs are recognized for high-speed processing, precise motion control, and reliable communication.

They are ideal for high performance sectors such as electronics manufacturing, packaging, and textile machinery.

The company’s focus on advanced manufacturing aligns with its broader “e-F@ctory” concept. This concept integrates automation with IoT and analytics to create smart factories.

ABB Ltd.

ABB is synonymous with innovation in robotics and industrial automation. The AC500 PLC family is modular and scalable.

It supports various communication standards, including PROFIBUS, Modbus, and EtherNet/IP.

Engineers can configure and program these systems through the Automation Builder software suite. This software combines PLC, HMI, and drive configuration in one environment.

ABB PLCs are used in manufacturing, process automation, renewable energy systems, and infrastructure projects.

They integrate seamlessly with ABB robots and drives. This creates highly efficient and synchronized control systems.

The AC500 also offers a safety PLC variant. This variant is designed for applications requiring functional safety up to SIL3.

Omron Corporation

Omron is a major Japanese manufacturer. It is known for innovation in sensors, control systems, and robotics.

Its PLC range includes the CP1 series, a compact yet powerful controller, and the CS1 series for large-scale automation systems.

Omron’s CX-Programmer software supports multiple IEC 61131-3 programming languages. Engineers can choose ladder logic, structured text, or function blocks.

Omron PLCs are valued for reliability, speed, and seamless communication with Omron’s sensors and motion devices.

They are widely used in packaging, manufacturing, robotics, and energy management.

Omron emphasizes interoperability and real-time control. This ensures smooth coordination between machines and production lines.

Delta Electronics

Delta Electronics, based in Taiwan, delivers efficient and cost-effective automation solutions. The DVP series offers a compact and affordable option for small machines. The AH series targets advanced automation applications.

It provides higher processing speeds and improved networking capabilities. Programming and system design are done through ISPSoft. This software follows IEC 61131-3 standards.

This ensures international compatibility. Delta PLCs are known for energy efficiency and reliable operation. They are also highly compatible with Delta’s drives, HMIs, and motion controllers.

These PLCs are widely used in packaging, printing, textiles, rubber, and plastics industries.

Delta’s growing investment in IIoT and smart manufacturing strengthens its position in Asia and other emerging markets.

Emerson Electric Co.

Emerson provides highly reliable automation and control solutions. This includes Programmable Automation Controllers (PACs).

These systems combine the robustness of traditional PLCs with the flexibility of PCs.

Emerson PACs are designed with modular and redundant architectures. This supports uninterrupted operation in critical applications.

The company’s solutions use open communication standards such as PROFINET and Modbus TCP.

This allows easy integration with third-party systems. Emerson PACs work seamlessly with its Experion software platform.

This provides a unified interface for monitoring, analytics, and control. Emerson controllers are widely used in process industries like oil and gas, chemical plants, and power generation.

Honeywell International Inc.

Honeywell offers a wide range of industrial control products. These products are designed for performance and connectivity. The ControlEdge PLC is IIoT-enabled. It has embedded OPC UA protocol support.

The MasterLogic ML200 provides fast and deterministic control for complex operations.

Honeywell PLCs integrate closely with the Experion Process Knowledge System. This creates a unified platform for plant control and data analysis.

These systems support remote diagnostics and secure cloud connectivity. They are ideal for distributed industrial networks.

Honeywell controllers are extensively used in oil and gas, chemical processing, water treatment, and power generation.

General Electric (GE) Vernova

GE Vernova delivers advanced automation and control systems through its PACSystems controllers.

These platforms provide multi-discipline control for discrete, process, and motion applications.

This helps industries optimize performance across diverse operations. The Proficy software suite from GE provides data analytics and visualization tools. It also includes powerful cloud integration features.

It enables predictive maintenance and energy optimization. The system also supports scalability.

GE PLCs and PACs are used in power generation, transportation, and utilities.They are crucial where reliability and interoperability are required.

Market Trends and Future Outlook

The global PLC market continues to grow. Industries are embracing smart manufacturing and digital transformation. Key trends include IIoT integration, edge computing, and AI-driven analytics.

Future PLCs are expected to combine faster processing with enhanced security. They will also provide real-time data connectivity.

Wireless communication, cloud-based control, and cybersecurity hardening are gaining momentum.

Factories are becoming more connected. PLCs are evolving from isolated controllers into networked intelligence hubs.

They can coordinate machines, collect data, and optimize operations autonomously.

The Asia-Pacific region remains a major growth driver. Rapid industrialization and investment in smart infrastructure fuel this growth.

Key Takeaways: Top PLC Controller Manufacturers

This article detailed how the global PLC market remains highly competitive. Each manufacturer offers unique strengths across industries.

Siemens, Rockwell, and Schneider continue to lead with large market shares and integrated ecosystems.

Mitsubishi, ABB, Omron, Delta, Emerson, Honeywell, and GE provide strong alternatives with specialized capabilities.

As the world moves toward intelligent, interconnected factories, PLCs are evolving into smarter, more secure, and data-driven control units.

The integration of IoT, AI, and cloud technologies ensures that PLCs will remain at the heart of industrial automation for decades.

FAQ: Top PLC Controller Manufacturers

Who are the top PLC manufacturers?

Siemens, Rockwell Automation, Schneider Electric, Mitsubishi, ABB, Omron, Delta, Emerson, Honeywell, and GE Vernova.

Which PLC brand is most popular worldwide?

Siemens leads globally, while Allen-Bradley (Rockwell) dominates in North America.

What makes Siemens PLCs unique?

They offer strong integration through the TIA Portal and a wide range from basic to high-end controllers.

What is Rockwell Automation known for?

Its Allen-Bradley PLCs provide excellent communication, safety, and reliability for industrial use.

Why choose Schneider Electric?

Its Modicon series supports IIoT applications and strong cybersecurity features.

What are Mitsubishi PLCs used for?

They’re ideal for high-speed and motion control in manufacturing and packaging.

What industries use ABB PLCs?

ABB systems are common in robotics, energy, and process automation.

What does Omron specialize in?

Omron focuses on smart sensors, robotics, and flexible PLC control systems.

Why is Delta Electronics popular?

Delta offers cost-effective and energy-efficient automation solutions.

What distinguishes Emerson and GE PLCs?

Both focus on reliability, modular PAC architectures, and process industry applications.

What are current PLC market trends?

Integration with IoT, edge computing, AI, and stronger cybersecurity.

Which region is growing fastest for PLCs?

Asia-Pacific leads due to rapid industrialization and smart manufacturing projects.