Actuators serve as the critical bridge between digital intelligence and physical motion. They are fundamental components in modern engineering systems.

They enable machines to interact with the physical world by converting an energy source into mechanical work.

Industries like automation and robotics are heavily reliant on them. This is similar to automotive systems and aerospace applications.

From opening and closing valves in a processing plant to positioning robotic arms, actuators play a critical role.

They transform control signals into mechanical action. Engineers must understand how actuators work.

This helps them to design more efficient and sophisticated systems. It also helps with troubleshooting faults and selecting the right technology for a given application.

This article explains the working principles of actuators. It also covers their main types, internal components, control methods, and applications.

What Is an Actuator?

An actuator is a device that converts an input signal and energy into physical movement. The movement can be linear, such as pushing or pulling. It can also be rotary, such as turning or rotating a shaft.

Sensors and actuators have a dissimilar relationship. Sensors detect physical quantities and convert them into signals.

On the other hand, actuators perform the opposite function. They take electrical, pneumatic, or hydraulic energy. They then produce mechanical motion.

Actuators are typically controlled by a controller such as a PLC or microcontroller. They may also be controlled by an industrial control system. The controller sends a command signal.

In response, the actuator moves to a specific position, applies force, or generates torque. The accuracy, speed, and force of this motion depend on the actuator type. They also depend on the actuator design.

Basic Working Principle of Actuators

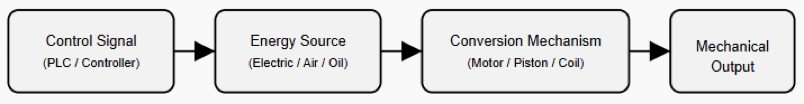

At their core, all actuators operate on the same basic principle. That principle is energy conversion.

An external energy source is supplied to the actuator. An internal mechanism converts that energy into motion. The process usually follows three steps.

First, a control signal is generated by a controller. This signal may be a voltage or current. It may also be an air pressure command or a digital instruction. Second, the power source provides enough energy to the actuator.

This energy depends on the nature of the system. It may include a pressurized fluid, compressed air, or electricity.

Finally, internal components convert this energy into mechanical movement. Motors are a vivid example of this. It also includes pistons or electromagnetic coils.

Main Components of an Actuator

Although actuator designs vary widely, most share common internal components. These components enable their operation. The power source feeds the actuator. It supplies the energy needed to produce motion.

As mentioned above, this energy depends on the nature of the system. It may consist of electrical power, compressed air, or hydraulic fluid under pressure. The drive mechanism converts this energy into motion.

Electric motors are a typical example. Also, it may incorporate pneumatic pistons or hydraulic cylinders. The control interface allows the actuator to receive commands from a controller.

These commands are often transmitted through electrical signals or pneumatic lines. Many actuators also include feedback elements.

These may be encoders or position sensors. They allow closed-loop control for improved accuracy.

These components work together to ensure smooth actuator movement. They also ensure reliable operation. Motion follows the desired command.

Types of Actuators Based on Energy Source

Electrical Actuators

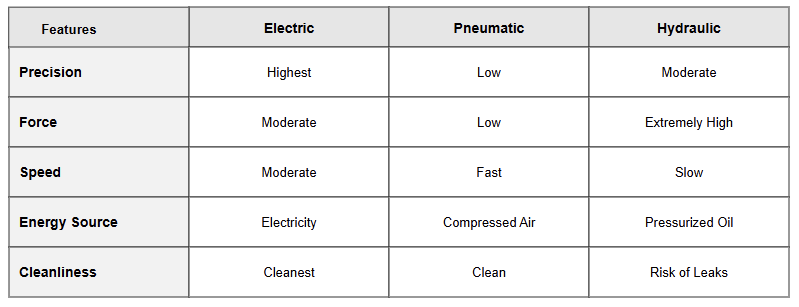

Electrical actuators use electrical energy to produce motion. They are among the most widely used actuators today. This is due to their precision, cleanliness, and ease of integration with control systems.

Typical examples include DC motors and AC motors. Stepper motors and servo motors are also widely used.

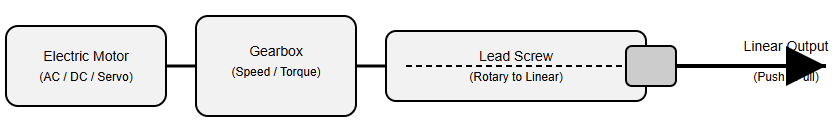

When applying electric current inside a motor coil, a magnetic field is generated. This is the main characteristic of all electrical actuators.

Then, this magnetic field interacts with conductors or permanent magnets. The interaction produces a torque that causes rotation.

Linear motion can be achieved by coupling the motor to mechanical elements. Belt drives are a typical example of these elements. It may also include lead screws and ball screws.

Electrical actuators are ideal for applications requiring precise position control. They also support variable speed operation. Easy programmability is another advantage.

Pneumatic Actuators

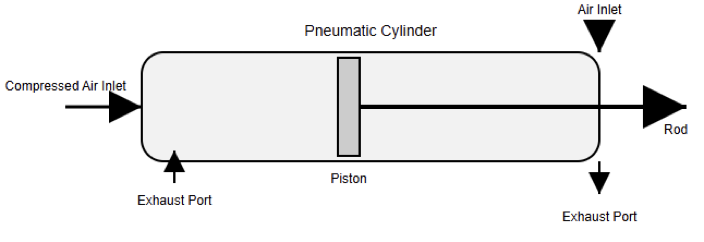

Compressed air is applied to create motion in pneumatic actuators. They are commonly used in industrial automation systems.

Common applications include clamping and lifting. Also, they are mainly found in pushing and sorting. Pneumatic actuators are known for their simplicity.

They also offer fast response and high robustness. The basic working principle involves directing compressed air into a cylinder. The air pressure acts on a piston. This generates force and causes linear movement.

Directional control valves control the airflow. They determine the direction of motion. Rotary pneumatic actuators use different mechanisms. Common examples include vanes or rack and pinion systems.

Pneumatic actuators are well-suited for environments with electrical safety concerns. However, they offer limited precision. This limitation appears when compared to electrical actuators.

Hydraulic Actuators

Pressurized liquid, usually oil, is applied in hydraulic actuators. The liquid is usually oil. They are capable of producing very high forces. These actuators are commonly used in heavy-duty applications.

Construction equipment and industrial presses are common examples. Plus, in aerospace systems, they are essential.

The way of operation of hydraulic actuators sending pressurized fluid into a cylinder. The fluid pushes against a piston.

Because liquids are nearly incompressible, hydraulic systems deliver smooth motion. They also provide very high power density.

Pressure and flow of fluid are controlled by control valves. As a result, an accurate control of force and speed is obtained.

More maintenance is required by hydraulic actuators despite their power. Most of the time, they contain potential leaks and contamination. This makes careful handling especially important.

Types of Actuators Based on Motion

Linear Actuators

Linear actuators produce straight-line motion. This type of motion is commonly used in lifting and positioning tasks.

It is also used for pushing and pulling applications. Examples include electric linear actuators.

Pneumatic and hydraulic cylinders are also common. The working principle depends on the energy source.

Electric linear actuators convert rotary motion into linear movement. This is done using a screw mechanism.

Pneumatic and hydraulic linear actuators rely on fluid pressure. The pressure acts on a piston to produce motion.

Linear actuators are widely used in automation systems. They are also found in medical equipment and adjustable platforms.

Rotary Actuators

Rotary actuators produce rotational motion. This motion is usually limited to a certain angle. In some cases, it may be continuous rotation. Electric motors are the most common rotary actuators.

Pneumatic and hydraulic rotary actuators are also widely used. Rotary actuators convert energy into torque.

The torque causes a shaft to rotate. This motion can drive gears or turn valves. It can also rotate mechanical assemblies.

The amount of rotation and torque depends on the design. Operating conditions also play an important role.

Control of Actuators

Actuators must respond adequately to control commands. Actuator controls are in charge of this task. They also affect reliability.

Control can be either open-loop or closed-loop. In open-loop control, the controller sends a command without feedback.

No feedback is received from the actuator. This approach is simple. However, it is less accurate.

It cannot correct for disturbances or load changes. Stepper motors often operate using open-loop control.

Closed-loop control uses feedback from sensors. These sensors may include encoders or position transducers.

The controller compares the actual position with the desired value. It continuously adjusts the control signal.

Servo actuators commonly use closed-loop control. This allows high precision and dynamic performance.

Actuator Performance Characteristics

Several key parameters define actuator performance. Force or torque indicates how much load the actuator can handle.

Speed determines how fast the actuator can move. Stroke length or rotation angle defines the range of motion.

Accuracy and repeatability describe positioning performance. Other important factors include duty cycle and efficiency.

Environmental resistance is also important. Selecting the right actuator requires balancing these characteristics.

Application requirements must always be considered. The next table shows the comparison of different actuators.

Applications of Actuators

Actuators are used across a wide range of industries. In industrial automation, they control valves and conveyors.

They also operate robotic arms. In robotics, actuators enable the movement of joints. They also control end effectors.

Automotive systems use actuators for throttle control. They are also used in braking and seat adjustment.

In aerospace, actuators control flight surfaces. Landing gear systems also rely on actuators.

Consumer devices use actuators as well. Printers and cameras are good examples. It may also include smart home systems.

Their versatility makes actuators indispensable. This applies to both simple and complex systems.

Common Challenges and Limitations

Challenges are common in any equipment. In this case, actuators are not an exception. Electrical actuators may overheat under heavy loads.

Pneumatic actuators can suffer from air leaks. They also offer limited precision. Hydraulic actuators require careful maintenance.

This helps prevent fluid contamination and leakage. Actuator performance can easily be affected by environmental conditions. Dust and temperature are the main examples. Also, it includes moisture and vibration.

Proper selection is essential. Correct installation and regular maintenance are also critical. These steps ensure long-term reliability.

Conclusion

This article discussed the working principles of actuators. It the detailed their main types, internal components, control methods, and real-world applications. Actuators are the driving force behind motion in modern engineering systems.

They transform energy and control signals into mechanical movement. Better systems can be designed if engineers understand how actuators work. This includes knowledge of energy sources, internal components, and motion types.

Control methods are equally important. Each actuator type offers unique advantages. Each also has limitations. Correct selection is critical to achieving optimal performance.

Actuators will remain essential for continue advance of automation and robotics. They enable machines to move, interact, and respond intelligently to the physical world.

Frequently Asked Questions

What is an actuator?

An actuator is a device that converts an energy source into controlled motion, allowing a machine or system to move or operate a mechanism.

It acts like the “muscles” of a machine by activating movement based on a control signal.

How do actuators work?

Actuators receive an input signal from a controller and take energy, typically electrical, pneumatic, or hydraulic, and convert it into mechanical motion, either linear or rotary, to perform useful work.

What types of motion can actuators produce?

Actuators generally produce linear motion (straight line) or rotary motion (rotation around an axis), depending on design and application requirements.

What energy sources do actuators use?

Common energy sources include electricity for electric motors, compressed air for pneumatic actuators, and pressurized fluid for hydraulic actuators. Each type suits different forces, speeds, and environmental needs.

What is the role of the control signal?

The control signal tells the actuator what action to perform, such as move to a position or apply a force, so that its motion matches the commanded task from a PLC, microcontroller, or another control system.