Industrial automation is changing and factories are becoming smarter. They are using more connected devices than ever before. These devices are not only sensors and machines, but also advanced controllers, cameras, and industrial robots.

Each device generates large amounts of valuable data. Edge computing is a key part of this change because it processes data closer to its source.

This is at the “edge” of the network. In factories, this means the shop floor, production line, or even individual machines.

Processing data locally instead of sending it far away creates faster responses, which brings many benefits for industrial automation.

It reduces delays and improves reliability. It also supports modern applications like predictive maintenance, robotics, and energy efficiency.

This article explains what edge computing is, its role in industrial automation, benefits, challenges, and finally, its future.

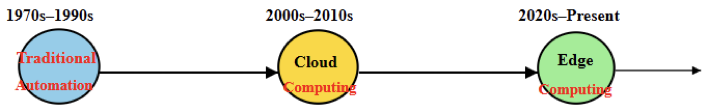

The shift from cloud to edge

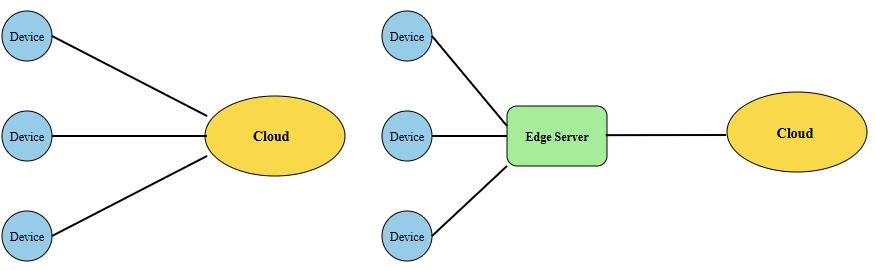

Traditionally, data from factory sensors was sent to a central data center. This was for storage, processing, and analysis. Engineers would collect data, send it to the cloud, and wait for results.

But this can cause delays, called latency. Latency is a big problem for real-time automation.

Even a small delay of a few milliseconds can stop a robot arm from reacting correctly.

It can cause defects on a fast-moving assembly line. It can even affect safety systems that need instant action.

Cloud computing also has high costs for bandwidth. Industrial Internet of Things (IIoT) devices may produce gigabytes of data every second. Sending everything to the cloud wastes resources and money.

Edge computing offers a different approach. It puts processing power near the data source.

Devices like edge gateways, rugged servers, or intelligent PLCs do the work. These devices are installed directly in factories.

This local processing reduces latency. It improves responsiveness. It allows for real-time decision-making.

Operators and machines can act immediately based on local insights. At the same time, only important summaries or trends are sent to the cloud for higher-level use.

Architecture of industrial edge computing

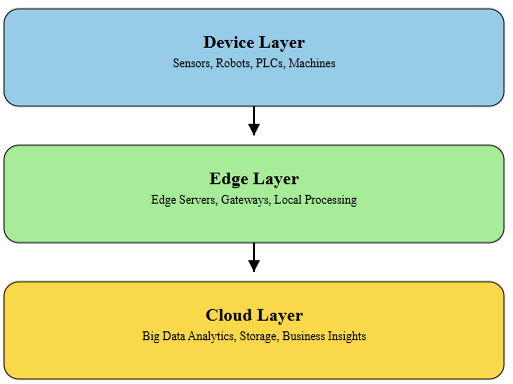

The architecture of industrial edge computing can be thought of in layers. Each layer has its own role and purpose.

Device layer

This is the base layer. It includes all the devices that generate data. Examples are sensors, robots, and programmable logic controllers (PLCs). These devices collect huge amounts of data every second.

In a smart factory, hundreds of devices may be connected. They measure temperature, vibration, pressure, energy use, or product quality.

Without processing, this raw data is too large to handle. That is why the next layer is important.

Edge layer

This layer is right above the device layer. It contains edge servers and gateways. These process data locally and in real-time.

They filter out unnecessary or repetitive information. Only critical information is forwarded to the cloud.

For example, an edge device can check vibration data from a motor. If it detects an unusual pattern, it can send an alert instantly.

It does not need to wait for cloud approval. This layer is key for low-latency actions.

Cloud layer

This is the highest layer. It receives aggregated and analyzed data from the edge layer.

It is used for long-term storage, big data analytics, and historical insights. It helps with higher-level business decisions.

Managers can use this information for planning, forecasting, and improving efficiency. While the edge ensures fast responses, the cloud provides the big picture.

Benefits of edge computing

Low latency and real-time control

Speed is vital in industrial settings. Edge computing eliminates the delay of sending data to the cloud. Machines can react instantly.

For example, a robot can stop when a worker enters its zone. A conveyor belt can pause when a defective product is detected. This is crucial for safety-critical systems.

Optimized bandwidth

Industrial IoT devices produce massive amounts of data. Sending all this raw data to the cloud consumes bandwidth.

Edge computing processes data locally. It sends only relevant insights, like alarms or performance summaries, to the cloud. This reduces bandwidth usage and costs significantly.

Enhanced security

Processing sensitive data locally keeps it more secure. It reduces the risk of data being intercepted during transit to the cloud.

Many factories handle confidential production processes. Keeping this information on-site helps with data privacy and compliance with regulations.

Improved operational efficiency

Real-time insights on the factory floor help optimize processes. Machines can adjust automatically.

Operators can make faster decisions. This increases productivity and reduces waste.

High reliability

Edge systems can function even when cloud connectivity is lost. This is vital for remote sites or areas with poor internet.

For example, a mining site or offshore platform can still operate locally. This ensures operational continuity and safety.

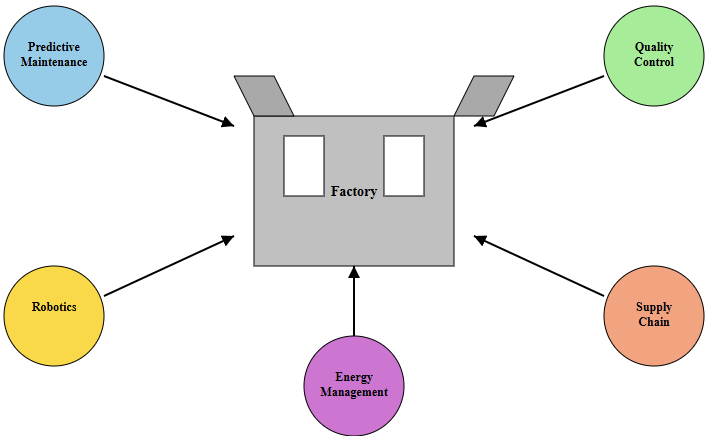

Use cases in industrial automation

Predictive maintenance

Sensors on machines monitor performance. Edge devices analyze this data in real-time. They can detect early signs of a potential failure.

For instance, vibration data may show that a motor bearing is wearing out. This allows maintenance to be scheduled before a breakdown occurs. The result is less downtime and lower costs.

Automated quality control

High-speed cameras and sensors inspect products on the assembly line. An edge device processes the images instantly.

If it sees a defect, it can reject the product in milliseconds. This improves product quality, reduces waste, and maintains consistency.

Robotics and autonomous systems

Autonomous robots need to make split-second decisions. They process data from their sensors locally.

This allows them to navigate safely and perform tasks in real-time. Without edge processing, delays could cause collisions or inefficiency.

Supply chain optimization

Edge devices track inventory and monitor vehicles in real-time. For example, smart tags can report stock levels instantly.

Processing this data on-site allows for immediate adjustments. This helps optimize logistics and respond quickly to disruptions.

Energy management

Edge systems can monitor energy usage across a plant. They identify energy-intensive processes.

They can automatically turn off idle machines or adjust settings to save power. This reduces energy costs and supports sustainability goals.

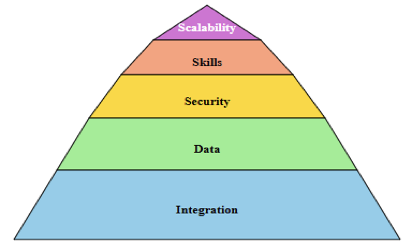

Challenges of industrial edge computing

Integration with legacy systems

Many factories use older equipment. This equipment was not designed for modern digital architectures.

Integrating edge solutions with these machines can be complex and expensive. Custom adapters or upgrades may be needed.

Data management

Factories generate huge volumes of data. Managing and storing this data locally requires robust infrastructure.

If not planned well, local systems can become overwhelmed. Companies must design scalable storage and processing solutions.

Security concerns

Edge computing increases the number of potential entry points for cyberattacks. Each edge device can be a vulnerability.

Hackers may target gateways or servers. Strong security protocols and constant monitoring are necessary.

Skilled workforce

Managing edge infrastructure needs specialized skills. Workers must understand networking, cybersecurity, and industrial systems.

Many companies must invest in training or hire new personnel. Without skilled staff, projects may fail.

Scalability

Edge solutions must be able to grow with the business. Starting with pilot projects and planning for expansion is important.

Companies should design architectures that can scale easily without replacing everything.

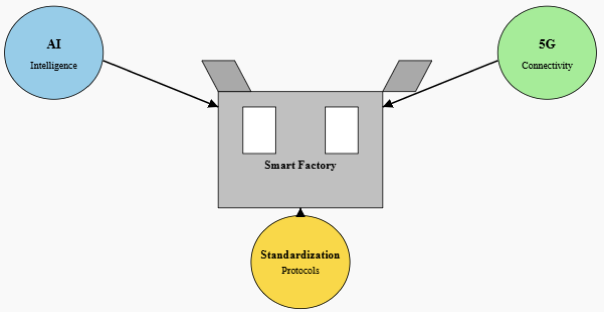

The future of industrial edge computing

Convergence with 5G

5G networks offer high bandwidth and low latency. They enable seamless machine-to-machine communication.

With 5G, mobile robots and wireless sensors can exchange data instantly. This will further enhance industrial edge applications and expand flexibility on the factory floor.

Advancements in AI

AI models are becoming more powerful and efficient. They can be deployed directly on edge devices.

This will enable more intelligent and automated decision-making. For example, AI at the edge can predict quality issues, optimize robot movements, or adjust production schedules in real-time.

Standardization

Currently, the market has many different solutions. Each vendor provides its own hardware and software.

Standardization is needed for easier implementation. Open standards will simplify integration, reduce costs, and accelerate adoption of edge computing.

Key takeaways: Edge Computing in Industrial Automation

The present article detailed what edge computing is, its role in industrial automation, benefits, challenges, and finally, the future of this edge computing.

From this discussion, and without hesitation, we can say that edge computing is driving the next industrial revolution.

It moves data processing closer to the source and reduces latency and improves efficiency. It also enhances security and reliability.

Furthermore, challenges like legacy system integration and security must be addressed.

Skilled staff and strong planning are essential. But with careful preparation, the benefits are immense.

In addition, the future of manufacturing is autonomous and intelligent. Edge computing is a key enabler of this future. It bridges the gap between devices, people, and the cloud. It empowers industries to be faster, smarter, and more sustainable.

FAQ: Edge Computing in Industrial Automation

What is edge computing and how is it different from cloud computing?

Edge computing means processing data close to where it is generated (machines, sensors, etc.), instead of sending everything to a distant cloud. This reduces latency, bandwidth usage, and often improves reliability.

Why is low latency important in industrial automation?

Many industrial tasks require instant or near-instant responses — e.g. safety systems, robotics, real-time quality control.

Delays (latency) can lead to defects, safety hazards, and inefficiencies. Edge computing helps by processing data locally so decisions happen quickly.

What kinds of use cases are there for edge computing in factories?

Some common ones:

- Predictive maintenance (monitoring machine health and detecting failures early).

- Quality control / visual inspection using computer vision.

- Robotics and autonomous systems (robots that need fast sensor feedback).

- Supply chain or warehouse optimization (inventory tracking, real-time visibility).

- Energy management (monitoring usage, shutting off idle machines, optimizing consumption).

What benefits can companies expect from deploying edge computing?

- Faster response times and real-time control.

- Reduced bandwidth costs and lower cloud storage/transfer fees, since not all data is sent offsite.

- Enhanced security and data privacy (sensitive data can remain local).

- Improved operational resilience (able to operate even with unreliable internet).

- Better cost efficiency in the long run, especially when many devices are involved.

What are the challenges or drawbacks of edge computing in industrial settings?

- Integration with legacy systems (older machines not built for modern connectivity) can be difficult.

- Limited computing resources on edge devices: less CPU, memory, storage than cloud data centers.

- Security risks: each edge device can be a potential attack surface. Maintaining updates, ensuring encryption, securing physical access all matter.

- Hardware management and maintenance are more complex when many edge devices are deployed.

- Scalability: ensuring solutions grow well without overhauling everything.

How does edge computing help with security and compliance?

Because data can be processed locally, there is less data in transit over external networks.

That reduces exposure to interception or external threats. It helps with data sovereignty rules, privacy laws, or industry-specific compliance.

Is internet connectivity still needed? What happens when connectivity fails?

Yes, connectivity helps for sending aggregated data, updates, or for cloud-based analytics.

But edge systems are designed to continue functioning even with intermittent or no internet. They carry out local control, safety, and monitoring even when disconnected.

What role do AI and machine learning play at the edge?

AI/ML enable more intelligent analytics, anomaly detection, predictive models, and automation.

When deployed at the edge, they can act immediately on sensor data. For example, image recognition on defect detection, or anomaly detection in vibrations.

How does 5G interact with edge computing?

5G offers high bandwidth and low latency wireless connectivity. It allows edge devices and sensors to communicate more reliably.

It enables you to place edge nodes further from wired infrastructure. It also supports mobile or moving devices.

When is edge computing not the best solution?

- When latency is not critical and cloud-based solutions are already meeting needs.

- When the cost of deploying and maintaining many edge devices outweighs the benefits.

- If infrastructure (power, cooling, environmental protection) is not sufficient for edge hardware.

- When data volumes aren’t large or when connectivity is reliable and affordable, so that cloud approaches make more sense. (In short: it depends on the use-case.)

How should companies plan for scaling edge computing deployments?

- Start with pilot projects to validate use-cases.

- Use modular, flexible architectures so you can expand.

- Ensure hardware, software, and network standardization for interoperability.

- Plan for device lifecycle: updates, security, maintenance.

- Monitor total cost of ownership (TCO) including hardware, operations, and staff training.

What hardware is needed for edge computing in industrial automation?

Edge computers, gateways, ruggedized servers, sensors with computing capability, PLCs with more advanced functionality.

They often need to be durable, able to handle vibration, temperature extremes, dust, etc. Also good networking (wired and/or wireless) and sometimes specialized accelerators (GPUs, TPUs) for AI workloads.

What standards or interoperability issues exist?

The market has many vendors, many proprietary systems. Standards like OPC UA, TSN (Time Sensitive Networking), and cross-vendor frameworks are becoming more important. Interoperability helps reduce integration costs