In modern engineering and industrial systems, detecting and measuring physical quantities is essential. These quantities must also be converted into usable signals.

Applications range from temperature control in furnaces to pressure monitoring in pipelines.

Motion detection in robotics is another common example. Devices known as sensors and transducers perform these tasks. In the area of measurement and control systems, they play a critical role.

Notice that these terminologies are not identical even if they are often used interchangeably.

This confusion can cause errors in system design and instrumentation selection. This article explains the concepts of sensors and transducers.

It describes their operating principles. It also clearly outlines the differences between them using practical examples and suggested diagrams.

Understanding Measurement Systems

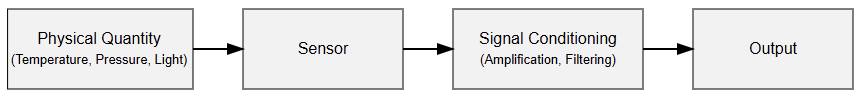

Every measurement system follows a logical sequence. A physical quantity is a measurable property found in the real world.

Examples include temperature, pressure, displacement, and light. This quantity cannot be processed directly by control systems or computers.

The quantity must first be detected. It must then be converted into an interpretable form. This form allows transmission, processing, or analysis.

This conversion process is central to instrumentation engineering. Several devices may be involved.

Some detect physical phenomena. Others convert energy, condition signals, or transmit information.

Sensors and transducers operate within this chain. Their roles are distinct and hierarchical.

The following figure indicates a block diagram showing physical quantity, sensor, signal conditioning, and output.

What is a sensor?

A sensor is often defined as a device that receives and responds to a signal or stimulus.

The stimulus is the quantity, property, or condition that is sensed and converted into an electrical signal.

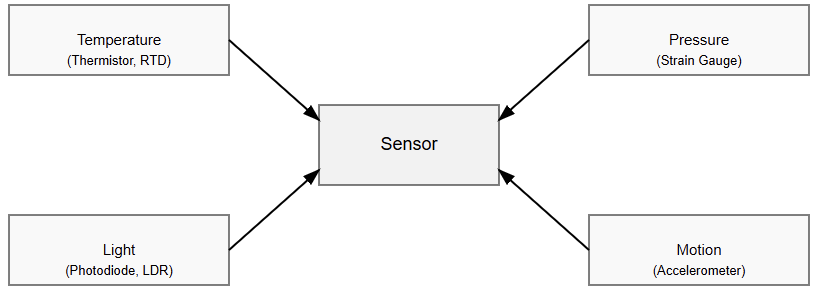

It might be temperature, pressure, force, light, humidity, gas concentration, or motion. The primary role of a sensor is detection.

A sensor does not necessarily provide a standardized electrical output. In many cases, it produces a change in a physical property.

For example, an RTD changes resistance as temperature varies. A thermistor behaves similarly but with nonlinear characteristics.

These devices sense temperature effectively. However, their outputs are not directly usable by control systems.

Sensors are therefore considered the first element in a measurement chain. They are in direct contact with the process or environment.

Careful selection is of key importance. Durability, repeatability, and accuracy must match operating conditions. The next figure shows an illustration of different physical quantities interacting with sensors.

Characteristics of Sensors

Sensors are defined by several performance parameters. These include sensitivity, range, accuracy, resolution, and response time.

Sensitivity describes output change relative to input change. Range defines the limits of reliable detection.

Environmental robustness is also critical. Take into account that industrial sensors may face vibration and moisture.

In addition, face corrosive chemicals and/or extreme temperatures. For this reason, adequate protective housings or coatings are often required.

A sensor alone may not produce a usable signal. Additional circuitry is often needed. This circuitry converts, amplifies, or standardizes the output.

What Is the Meaning of a Transducer?

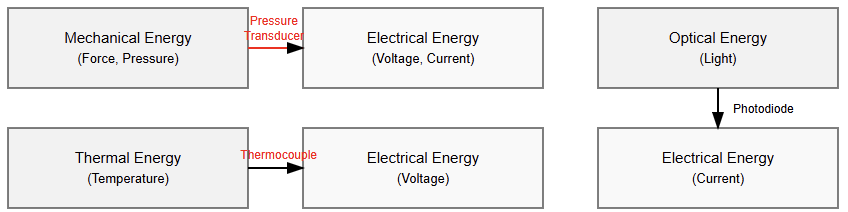

A transducer converts energy (variation) from one form to another. In the world of instrumentation, this usually means converting a physical quantity into an electrical signal.

This physical quantity could be pressure or brightness. A thermocouple is one of the most well-known examples. Hence, conversion is the defining function.

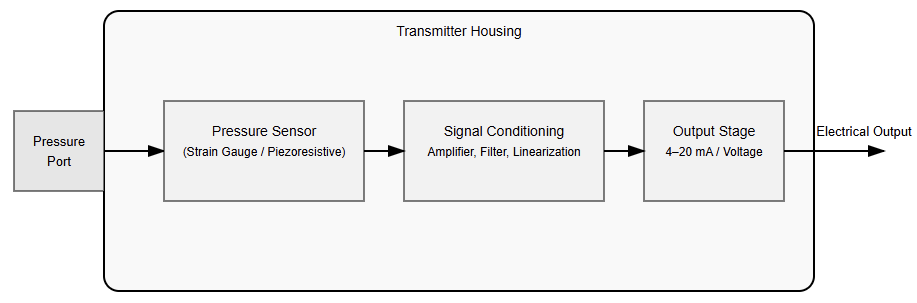

A pressure transducer is used to convert mechanical pressure into two formats. These formats could be voltage form or current form.

For instance, a microphone converts sound into an electrical signal. While a loudspeaker performs the reverse conversion.

In many systems, a transducer contains a sensor. It also includes components for signal conversion. The result is a usable and standardized output.

Types of Transducers

Transducers are commonly classified as input or output devices. Input transducers convert physical quantities into electrical signals. Examples include pressure accelerometers, thermocouples, and transducers.

Output transducers perform the opposite function. General actuators, solenoids, and motors convert electrical signals into physical action.

Transducers may also be active or passive. Active transducers generate output without external power.

Thermocouples are a typical example. Passive transducers require excitation. Strain gauges and RTDs fall into this category. This classification differs from sensors.

Sensors are grouped based on the quantities they detect rather than their energy conversion method.

Sensors and Transducers: Relationship

The relationship is best explained hierarchically. A sensor is often part of a transducer. The sensor detects the physical quantity. The transducer ensures usable energy conversion.

Consider an industrial pressure transmitter. A sensing element detects pressure-induced deformation. This sensing element changes resistance. On its own, it is only a sensor.

The transducer circuitry converts this change. It produces a standardized 4–20 mA signal. This signal can be transmitted reliably over long distances. All transducers contain sensors. Not all sensors are complete transducers.

Sensor and Transducer: Key Differences

The important difference is based in functionality of each one. A sensor detects a physical quantity.

A transducer converts energy. Detection indicates the presence of change. Conversion produces a usable output. Sensor outputs may be resistance or displacement changes.

Transducer outputs are typically voltage, current, or frequency. From a system perspective, sensors interface with the process.

Transducers interface with control systems. This distinction is important in specifications and procurement.

Examples Illustrating the Difference

A bimetallic strip bends whenever there is a change on temperature change. It senses temperature, but it does not generate an electrical signal. It functions as a sensor.

The system turns into a transducer when the aforementioned motion is converted into an electrical signal.

A light-dependent resistor changes resistance with light intensity. It is a sensor. When paired with a circuit that outputs voltage, it becomes a light transducer.

In industry, datasheets often reflect this distinction. The sensing element is called a sensor. The complete device is called a transducer or transmitter.

Applications in Engineering and Industry

Sensors and transducers are used across many fields. These include robotics, automotive systems, and most importantly, automation. In addition, they are also useful in medical equipment and electronics.

In control systems, accurate sensing ensures stability. Reliable transduction ensures compatibility with controllers.

In process industries, transmitters enable remote monitoring. In robotics, sensors detect position and force.

Transducers convert these detections into electrical signals. This enables real-time control. Understanding the distinction improves device selection.

Common Misunderstanding

A large number of technicians and/or engineers have a common misconception. This is to think that sensors and transducers are identical. This is not true. Every transducer includes sensing, but not every sensor performs transduction.

Another misunderstanding is assuming sensors always produce electrical outputs. Many do not.

Loose terminology contributes to confusion. One of the essential requisites in engineering communication is precise language.

A Sensor and a Transducer?

The choice depends on application needs. Simple detection may only require a sensor. System integration usually requires a transducer.

Engineers must consider signal compatibility and the environment. Accuracy and cost are also factors. Complete transducers often reduce complexity and improve reliability.

Key Takeaways: Transducer vs Sensor

This article addressed the fundamental differences between sensors and transducers. It clarified how both are used in measurement systems. A sensor is responsible for detecting physical quantities.

These quantities include temperature, pressure, light, or motion. A transducer performs energy conversion.

It produces a usable output signal, most often electrical. Although the terms are often used interchangeably, they represent different functions.

Sensors are closest to the physical process. Transducers interface directly with control and monitoring systems.

Understanding this distinction improves device selection. It also reduces design errors and specification ambiguity.

Clear terminology supports reliable system design. It ultimately leads to better performance in industrial and engineering applications.

FAQ: Transducer vs Sensor

What is a sensor?

A sensor detects a physical quantity and responds to changes in the environment.

What is a transducer?

A transducer converts one form of energy into another, usually into an electrical signal.

Are sensors and transducers the same?

No. A sensor detects, while a transducer converts energy into a usable output.

Does a transducer contain a sensor?

Yes, most measurement transducers include a sensor as the sensing element.

Can a sensor work without being a transducer?

Yes. Some sensors only change a physical property and do not provide a usable output.

Does a sensor always produce an electrical signal?

No. Some sensors produce resistance, capacitance, or mechanical changes.

What kind of output does a transducer provide?

Typically, a usable electrical signal is a voltage, current, or frequency.

Is every sensor a transducer?

Not necessarily. Only sensors that perform energy conversion qualify as transducers.

Why is the difference important?

It helps in proper device selection and clear engineering communication.

Can a transducer work in reverse?

Yes. Some transducers act as actuators, converting electrical energy into physical output.