A Variable Frequency Drive (VFD) is a device that controls the speed of an AC motor. It does this by adjusting the frequency and voltage supplied to the motor. Unlike basic motor controllers that only switch a motor on or off, a VFD allows precise speed control.

This improves efficiency, enhances process control, and reduces mechanical wear. In simple terms, a VFD converts AC power into DC and then back to AC. However, it does so at a selectable frequency and voltage.

This technology is widely used in modern industry because it helps save energy, prolongs equipment life, and allows processes to run more smoothly. This article explains what a VFD is, how it works, its benefits, common applications, and future trends.

Evolution of Motor Control

Before VFDs, motors could only operate in two states: ON or OFF. It was like driving a car that could only go full speed or stop. This caused a lot of energy waste in factories. Motors often did not need full speed, but they ran at maximum power anyway.

Early solutions tried to control speed using belts, gears, or mechanical clutches. These methods were inefficient and took up a lot of space. In the mid-20th century, engineers, including Vladimir G. Lukyanov, developed early variable-speed motor systems.

These systems allowed motors to run at different speeds depending on demand. Advances in power electronics, particularly the development of IGBTs (Insulated-Gate Bipolar Transistors), made VFDs more practical and reliable.

The first commercial VFD appeared in 1967. Since then, VFDs have become essential in manufacturing, HVAC systems, water management, and many other industries. Over time, they became smaller, more efficient, and capable of controlling larger motors.

Modern VFDs can communicate with other devices and even the internet, making them part of smart industrial systems.

VFD: Working Principle

A VFD controls motor speed through three main stages: the rectifier, the DC bus, and the inverter. These stages work together to convert and shape the electrical power so the motor runs exactly as required.

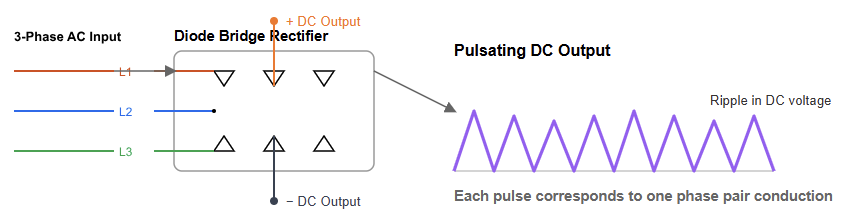

Rectifier Stage

The rectifier is the first stage. It converts incoming AC power into DC using diodes. Diodes act like one-way gates, letting current flow in only one direction. The output is a pulsating DC waveform.

This DC power is not yet smooth, but it is ready to be filtered in the next stage. The figure below shows the rectifier stage of a VFD.

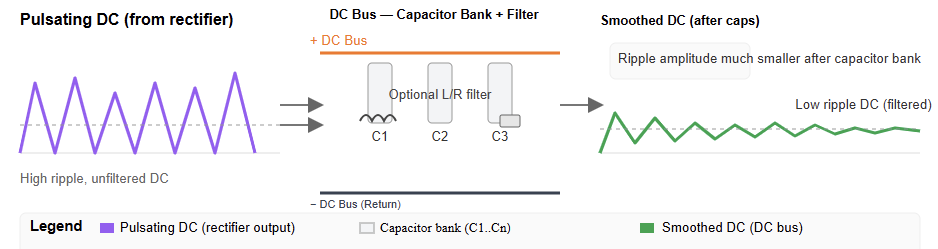

DC Bus Stage

The DC bus is the next stage. It smooths the pulsating DC using large capacitors. These capacitors act as filters, producing a stable DC voltage. This stable energy is then sent to the inverter. The DC bus also stores energy temporarily.

This is useful when the motor needs to accelerate quickly or handle sudden load changes. The figure below illustrates the DC bus stage of a VFD.

Inverter Stage

The inverter converts the stable DC back to AC. However, the AC now has a variable frequency and voltage. It uses high-speed switches called IGBTs. These switches turn on and off rapidly in a pattern called Pulse Width Modulation (PWM).

By adjusting the timing of these pulses, the VFD produces an AC output that precisely controls motor speed. This allows motors to run exactly as required for different processes. The figure below shows the inverter stage of a VFD.

Relationship between Frequency, Voltage, and Speed

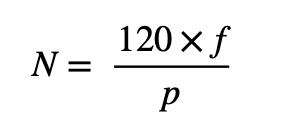

The speed of an AC motor is directly proportional to the frequency of the power supplied to it. This is governed by the formula:

Where:

N = Speed in revolution per minute (RPM)

F = Frequency in Hertz (Hz)

P = Number of motor poles

By controlling fre frequency (f), the VFI can precisely control the motor’s speed (N). To maintain a stable magnetic field and prevent motor overheating, the VFI also proportionally adjusts the voltage supplied to the motor. This is known as the Volts-per-Hertz (V/Hz) ratio.

Benefits of Using a VFD

Energy Efficiency and Cost Savings

VFDs save energy by running motors only as fast as needed. For fans, pumps, and compressors, even a small speed reduction can significantly cut energy use. For example, lowering motor speed by 20% can save about 50% of energy.

This reduces electricity bills and benefits the environment. Over time, these savings can pay for the VFD many times over.

Improved Process Control

A VFD lets you control motor acceleration, deceleration, and running speed. This is important in manufacturing, chemical processing, and conveyor systems. Smooth and precise motion ensures consistent product quality. It also prevents damage to equipment, such as belts, gears, and delicate materials being moved.

Extended Equipment Life

VFDs provide soft-start and soft-stop capabilities. This reduces mechanical stress on motors and connected equipment. Controlled acceleration and deceleration minimize wear on gears, couplings, and belts.

As a result, equipment lasts longer, requires less maintenance, and reduces unscheduled downtime.

Built-in Protection

VFDs include protective features for overvoltage, undervoltage, and overheating. These safety functions prevent motor damage and costly breakdowns. Some VFDs can even monitor vibration or temperature, providing early warning before a failure occurs.

Common Applications of VFDs

HVAC Systems

VFDs control fans, pumps, and compressors. They adjust airflow and water flow based on demand, reducing energy use.

Water and Wastewater Management

VFDs control pumps in water treatment plants and municipal systems. They optimize flow and pressure, prevent water hammer, and save energy.

Industrial Fans and Pumps

Large fans and pumps benefit from VFDs, operating efficiently under varying loads.

Conveyor Systems

VFDs allow smooth acceleration and deceleration. This protects products and machinery, improving efficiency and reducing maintenance.

Elevators and Escalators

VFDs ensure smooth motion and safe speed control. They reduce energy use by adjusting motor speed according to load.

Mining and Heavy Industry

VFDs manage large motors in crushers, mills, and conveyors. Precise speed control increases productivity and reduces wear on heavy machinery.

Agriculture

VFDs optimize irrigation pumps, grain handling, and ventilation systems. They save energy and extend equipment life.

Drawbacks and Considerations

Higher Initial Cost

VFDs are more expensive than simple starters. Energy savings often offset this over time.

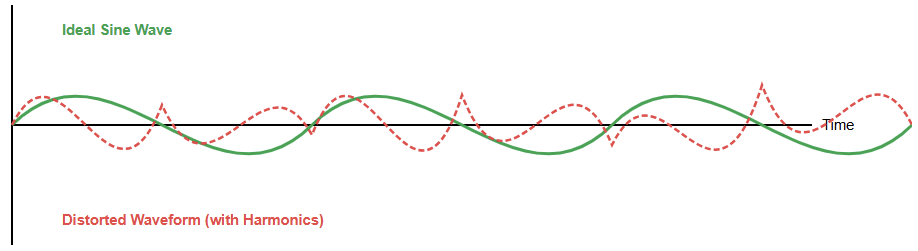

Harmonic Distortion

VFDs can create electrical noise called harmonics. This may affect other devices. Filters (passive or active) are used to reduce this problem. The figure below shows harmonic distortion.

Installation and Maintenance

Setting up a VFD requires skilled technicians. Proper configuration of programmable settings is necessary.

Motor Compatibility

Not all motors are suitable for VFDs. Older motors may not handle voltage stress well. It is best to use inverter-duty motors for reliable operation.

The Future of VFDs

VFDs are becoming smarter and more efficient. Many now connect to the Internet of Things (IoT) for remote monitoring, predictive maintenance, and data analysis. This allows factories to detect problems early, reduce downtime, and improve productivity.

New materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) make drives faster, smaller, and more efficient.

In renewable energy, VFDs control motors in wind turbines and solar systems. They help balance power flow to the grid.

Advanced VFDs can even coordinate multiple motors for complex industrial systems, reducing energy use and increasing reliability.

Key Takeaways: What Does VFD Mean?

This article explained what a VFD is, how it works, its benefits, applications, and future trends. A VFD is more than just a motor controller. It is a smart device that saves energy, improves performance, and extends equipment life.

By precisely converting and controlling power, motors run exactly as needed. Although VFDs cost more initially, energy savings and reliability quickly offset the cost.

With IoT integration and advanced semiconductors, VFDs will remain essential in modern industry. They are key to creating cleaner, smarter, and more efficient systems worldwide.

FAQ: What Does VFD Mean?

What is a VFD?

A VFD is a motor controller that varies the frequency and voltage supplied to an AC motor so you can control its speed and torque.

How does a VFD work?

It converts incoming AC power to DC (via a rectifier), smooths the DC (via a DC-bus), then inverts it back to AC with a variable frequency and voltage to control the motor.

Why use a VFD instead of just running a motor at full speed?

Because you can match the motor speed to what the process really needs. That leads to energy savings, lower mechanical wear, and better process control.

Where are VFDs commonly used?

They’re used in pumps, fans, compressors, conveyors, HVAC systems, and any rotating equipment where the load varies.

Can a VFD damage a motor?

If improperly sized, wired, or installed, yes, motors may be subject to higher voltage stress, harmonics, or cooling issues. But when properly used, a VFD actually extends motor life.

What are the main benefits of using a VFD?

Key benefits: energy savings, speed control, smoother start-stop, less mechanical stress, and process optimization.

What are some drawbacks or things to watch out for?

Higher initial cost, need for correct installation and settings, potential harmonic distortion in the supply line, motor compatibility issues.

How do I choose the right VFD for my application?

You’ll look at the motor’s rated power, voltage, phase, speed range, load type (constant vs variable), control features, installation environment, and compatibility.

How long do VFDs last?

With proper installation, cooling, and maintenance, VFDs often last 10-15 years or more.

What’s the difference between a VFD, VSD and inverter drive?

These terms are often used interchangeably. A VFD (Variable Frequency Drive) is a type of variable speed drive (VSD). “Inverter drive” is another name focusing on the AC-to-AC conversion aspect.