A relay is one of the most essential components in electrical systems. It acts as an electrically operated switch that allows one circuit to control another. A low-power signal can operate a high-power device safely through this mechanism.

Relays are important because they provide electrical isolation between control and load circuits. This ensures safe and reliable operation. They also make it possible to control large systems remotely or automatically.

This article introduces the main types of relays and explains how they work. It discusses types of relays: electromechanical, solid-state, and thermal relays in detail. It also compares them with contactors and shows where each device is best used.

Electromechanical Relay: How It Works

An electromechanical relay (EMR), works based on the principle of electromagnetism. Inside it, there is an iron core wrapped with a wire coil. This coil is part of the control circuit. When current flows through the coil, a magnetic field is produced.

The field attracts a movable metal lever called the armature. The armature connects to one or more electrical contacts. As it moves, the armature opens or closes the circuit that carries the load current.

When the control current stops, the magnetic field disappears. A spring then pulls the armature back to its normal position.

This process makes or breaks the electrical connection physically. It allows a low-power signal to control a larger circuit safely.

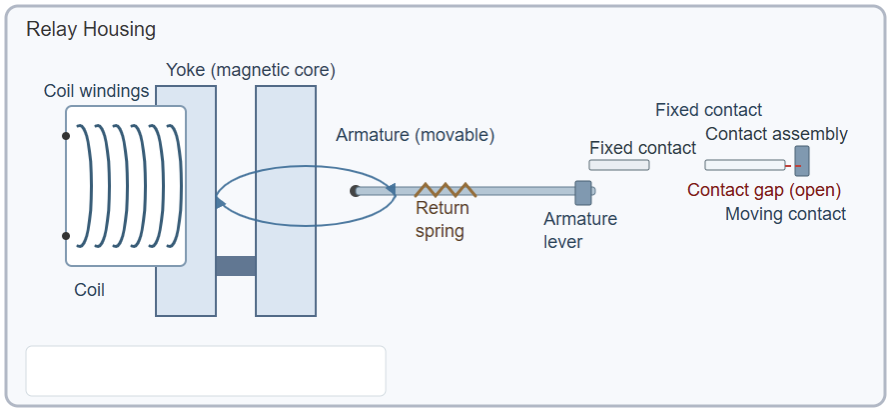

Key Components of an EMR

An electromechanical relay is made up of several important parts. The coil creates the magnetic field that drives the movement. The armature is the moving metal part that opens or closes the contacts.

The contacts are the points that actually complete or interrupt the load circuit. A spring provides the force to return the armature when the coil is de-energized. The yoke offers a low-resistance path for magnetic flux.

Finally, the housing protects all these components from dust, moisture, and vibration. These parts work together to perform reliable switching. A labeled diagram would make it easier to visualize each part

The following figure illustrates a diagram showing the coil, armature, spring, yoke, contacts and housing.

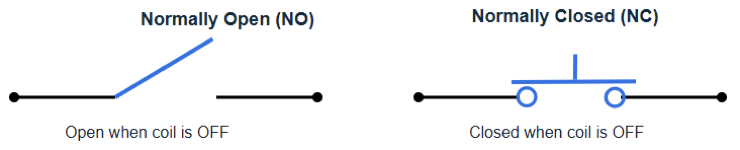

Types of EMR: Normally Open vs. Normally Closed Contacts

EMR can be designed in different configurations. The two main types are Normally Open (NO) and Normally Closed (NC). Normally Open contacts remain open when the relay coil is not energized.

Once the coil is powered, the contacts close, allowing current to flow. Normally Closed contacts work in the opposite way. They stay closed when no current flows through the coil. When the coil is energized, the contacts open, cutting the circuit.

Some relays include both NO and NC contacts. These are called Double-Throw (DT) relays. DT relays allow switching between two different circuits using one common terminal.

This makes them useful for applications that require alternate control paths. A figure showing how NO and NC contacts behave would be helpful. The above figure indicates a diagram of a NO vs NC contacts.

Solid-State Relays

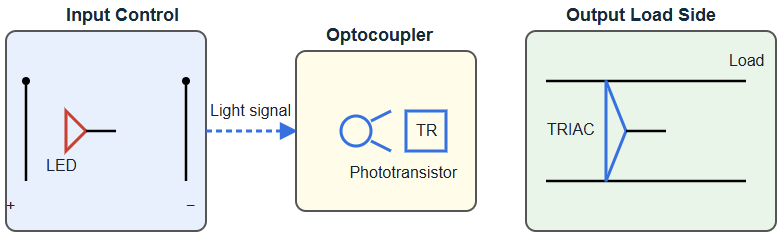

Solid-State Relays (SSRs), are modern devices that perform the same function as EMRs. However, they have no moving parts. Instead, they use semiconductor components to switch the circuit.

How do SSRs Work

An SSR receives a low-power control signal at its input. This signal activates an optocoupler, which transfers the control signal using light. The optocoupler then triggers a semiconductor device, such as a thyristor, TRIAC or MOSFET.

Once activated, this semiconductor allows current to flow through the load circuit. Because SSRs have no mechanical contacts, they operate silently. They also switch much faster than EMRs and last longer.

They are resistant to vibration and shock, which makes them ideal for demanding environments. However, SSRs have some limitations. They can produce heat during operation and often require cooling.

They are also more expensive than EMRs and usually have lower voltage and current ratings. Even with these drawbacks, SSRs are widely used in fast-switching and precise control systems.

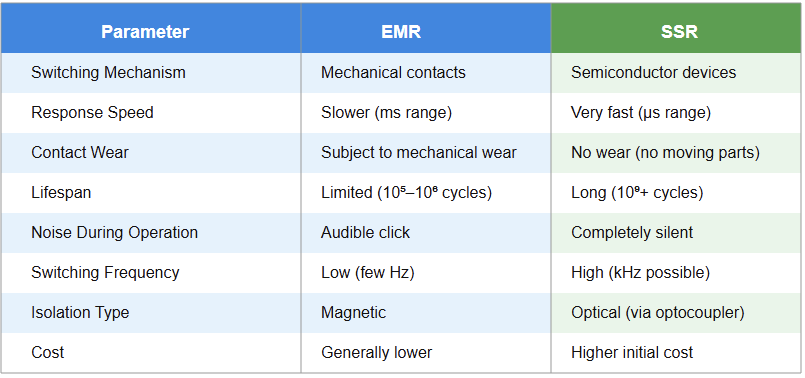

EMR vs. SSR: A Comparison

Choosing between an EMR and an SSR depends on the specific application. Each has clear advantages and disadvantages.

- Electromechanical relays are strong and can handle high current levels. They also provide complete electrical isolation between circuits. However, their moving parts wear out over time. This makes them slower and less durable in repetitive switching situations.

- Solid-state relays, by contrast, switch quickly and operate quietly. They have no moving contacts, so they last longer. They are excellent for precise and frequent operations.

Still, SSRs generate heat and usually cost more. Their voltage and current limits are also lower. Therefore, EMRs are best for general-purpose or heavy-duty applications, while SSRs are ideal for fast, low-noise systems.

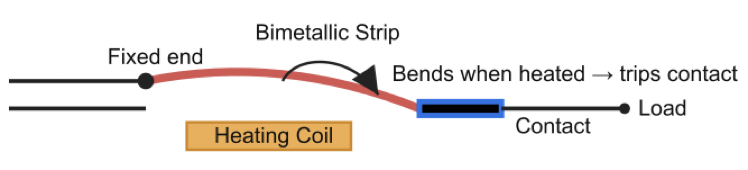

Thermal Relay: Working Principle

A thermal relay is used mainly to protect electric motors. It prevents damage caused by overheating or overload conditions.

The heart of a thermal relay is a bimetallic strip. It consists of two different metals with unequal rates of thermal expansion. When too much current flows through the circuit, the relay’s heating coil warms this strip.

As the strip heats, it bends because one metal expands more than the other. This bending motion moves a set of contacts and opens the circuit. When the circuit opens, the motor power is cut off, preventing overheating.

After the fault is cleared, the relay can be reset manually or automatically. This simple design makes thermal relays reliable and widely used.

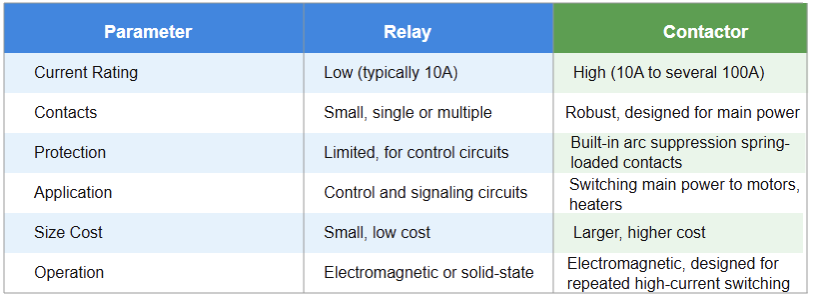

Relay vs. Contactor

A contactor is similar to a relay but built for much higher power. It is commonly used to control heavy electrical loads, typically above 10 amperes.

Relays are usually smaller and meant for low-power or control circuits. Contactors, on the other hand, are used for motors, lighting systems, and industrial heating loads. They have stronger contacts and special features for protection.

These include arc suppression, spring-loaded mechanisms, and auxiliary contacts for added safety. Contactors are built to handle high currents and frequent switching.

A relay often has both NO and NC contacts, while a contactor usually has only NO contacts for the main circuit. Contactors are larger and more durable, but also more expensive.

Common Applications

Relays are used everywhere in electrical systems. In vehicles, they control headlights, horns, and starters. In household appliances, they manage motors, compressors, and heating elements.

Furthermore, in industrial automation, relays play a key role in control panels and process systems. They are used for logic control, signal transmission, and safety interlocks.

In addition, in power systems, relays perform protection and switching functions. They isolate faults and prevent equipment damage. In modern smart systems, relays are connected to IoT networks for remote monitoring and control.

Because relays separate low-voltage control from high-voltage operation, they improve both safety and flexibility.

Their ability to handle a wide range of applications makes them essential in almost every electrical environment.

Key Takeaways: How does Relay Work?

This article reviewed the operating principles of different relay types, their structures, and their uses. Understanding these concepts is vital for anyone working with control circuits or automation equipment.

So, the study helped us to understand that, the electromechanical relays use magnetic force to move contacts.

Solid-state relays use semiconductors to switch quietly and quickly. And, finally thermal relays protect motors from overheating and overloads.

Furthermore, we learnt that for high-power circuits, contactors are used instead of standard relays.

Each type has its advantages depending on the application. Knowing how they work helps engineers design safer and more reliable systems.

In short, relays are essential switching devices in electrical and automation systems. They remain one of the most important components in our modern electrified world.

FAQ: How does Relay Work?

What is a relay?

A relay is an electrically operated switch that uses a small control signal to turn a larger electrical circuit on or off.

How does a relay function?

When current flows through the relay’s coil, it creates a magnetic field. This field moves an armature that opens or closes the circuit contacts.

What are the main parts of a relay?

A relay typically includes a coil, an armature, contacts, a spring, and a protective enclosure.

What is the purpose of using a relay?

It allows a low-power control circuit to safely operate a high-power load while providing electrical isolation between the two.

What is the difference between Normally Open (NO) and Normally Closed (NC) contacts?

NO contacts remain open until the relay is energized, while NC contacts stay closed until it is energized.

What types of relays are there?

Common types include electromechanical relays (EMR), solid-state relays (SSR), and thermal overload relays.

What is an electromechanical relay?

It is a relay that uses a magnetic coil and moving contacts to switch electrical circuits mechanically.

What is a solid-state relay?

A solid-state relay uses semiconductor components instead of moving parts to perform fast and silent switching.

How does a thermal relay protect motors?

It uses a bimetallic strip that bends when heated by excess current, opening the circuit to prevent motor damage.

What is the difference between a relay and a contactor?

A relay is used for low-power control, while a contactor is designed for switching higher power loads like motors.

Can relays be used in DC and AC circuits?

Yes. Different relay types are designed to work with either AC or DC power depending on the coil design.

Why are relays important in automation systems?

They allow control systems to switch devices remotely, automate processes, and ensure electrical safety.

How long does a relay last?

Electromechanical relays typically last from thousands to millions of cycles. Solid-state relays can last much longer because they have no moving parts.

What causes a relay to fail?

Common causes include worn contacts, coil overheating, excessive current, or mechanical fatigue.

How can you test if a relay is working?

You can check continuity across the contacts using a multimeter. When the coil is energized, the contact state should change.

What are typical applications of relays?

They are used in cars, home appliances, power systems, control panels, and industrial automation equipment.

Do relays consume much power?

No. They typically use a small amount of power to energize the coil compared to the load they control.

Can relays be controlled by microcontrollers like Arduino?

Yes. Many relays are designed to work with low-voltage control signals from microcontrollers and PLCs.

Are relays safe to use?

Yes, when properly rated and wired. They isolate low-voltage control circuits from high-voltage loads for safety.

What are the signs of a faulty relay?

A relay may click but not switch, fail to energize, show burned contacts, or cause intermittent circuit operation.