Programmable Logic Controller (PLC) programming is a vital skill in industrial automation. It controls machines and processes across sectors such as manufacturing, automotive, energy, and water treatment.

Acting as the “brains” of automation, PLCs ensure efficiency, precision, and safety in modern systems. Learning PLC programming can seem challenging because it requires knowledge of hardware, software, and logic.

However, it becomes much easier when you follow a structured learning path. By combining theory with hands-on practice, beginners can confidently design, program, and troubleshoot control systems.

How to Learn PLC Controller Programming

This guide provides a step-by-step pathway from basic concepts to advanced automation techniques.

It helps aspiring engineers, electricians, and technicians build a strong foundation for real-world industrial applications.

Step 1: Understand the Basics

Start by learning what a PLC is. A Programmable Logic Controller is a durable industrial computer.

It is designed specifically to control machines and processes automatically. PLCs receive input signals from sensors, switches, and other devices.

They send output signals to actuators such as motors, lamps, valves, and pumps. The PLC executes a program written to control these operations. This program responds to conditions detected by the input devices.

Before PLCs, control systems relied on relay panels. These panels were large, hard to maintain, and inflexible.

PLCs replaced these mechanical systems with digital logic. Changes can now be made by editing the program instead of rewiring.

Understanding the basics will make learning programming easier. You will also understand industrial automation history and evolution.

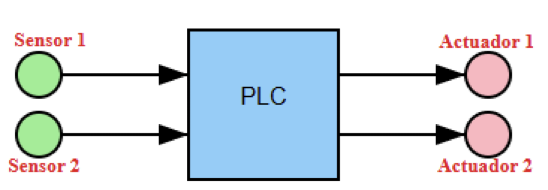

The figure below illustrates a simple diagram with a PLC positioned at the center.

Arrows indicate the direction of signals flowing from the input devices, such as sensors, to the PLC. The from the PLC to the output devices, such as actuators.

Step 2: Learn About PLC Hardware

Next, study the key hardware components of a PLC system. The main parts are the CPU, power supply, and input/output modules.

The CPU is the brain of the system. It executes logic instructions and makes decisions based on inputs.

The power supply provides electricity to the CPU and other modules. I/O modules connect the PLC to field devices like sensors, switches, and actuators. PLCs are available in compact or modular designs.

Compact PLCs have fixed inputs and outputs and suit small applications. Modular PLCs allow additional modules to be added. They are suitable for large or expandable systems.

Understanding how each component works helps in troubleshooting and system expansion.

Hands-on practice with a real or virtual PLC reinforces your understanding of the hardware layout.

Step 3: Choose a PLC Platform

Several manufacturers produce PLCs, including Siemens, Allen-Bradley, and Schneider Electric.

Each brand uses its own software environment and terminology. Allen-Bradley is common in North America, whereas Siemens is popular in Europe and Asia.

Beginners should choose one platform and focus on it first. Mastering one platform helps you understand general PLC principles. Later, adapting to other platforms becomes much easier.

Also, consider the availability of learning resources, tutorials, and simulation tools. Many manufacturers provide free materials, guides, and online training courses. Selecting the right platform with good resources accelerates your learning.

Step 4: Master Ladder Logic

Ladder Logic is the most common PLC programming language. It looks like an electrical circuit with two vertical rails and multiple horizontal rungs. It was designed for electricians and people familiar with relay diagrams.

Learn basic instructions such as XIC, XIO, and OTE. These are the building blocks of all Ladder Logic programs. Start with simple examples, like turning on a lamp when a switch is pressed.

Then move to more advanced logic using timers, counters, and interlocks. Visualizing how current flows in a circuit helps you understand Ladder Logic easily. Practice creating small programs and simulate them to reinforce learning.

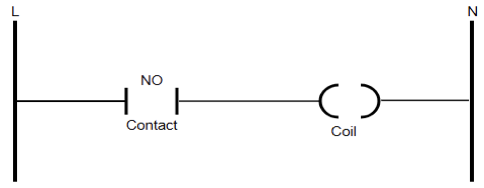

The upcoming figure details a diagram of a basic ladder logic rung. It shows a Normally Open (NO) contact connected to a coil. The rails are on the far left representing a power line (L), and right symbolizing a neutral (N).

Step 5: Get the Programming Software

Every PLC manufacturer provides proprietary programming software. Rockwell Automation uses RSLogix or Studio 5000. Siemens uses TIA Portal. Schneider Electric uses EcoStruxure Control Expert.

These tools let you write, test, and upload programs to your PLC. Most software has free or student versions ideal for learning. Explore the interface and try creating small projects.

Learn features such as tag management, cross-references, and diagnostics. These tools make programming and troubleshooting faster and more efficient.

Step 6: Use Simulation Software

You can practice PLC programming without owning physical hardware. Many software suites include simulation tools. Examples include PLCLogix 500 and OpenPLC Editor. Simulations allow you to test your logic safely.

You can see inputs, outputs, and timers work in real time. This saves money and prevents mistakes on real equipment.

Over time, you can add virtual sensors and motors for realistic simulations. Simulation is a safe and effective way to gain experience.

Step 7: Practice with Small Projects

Hands-on practice is essential for learning PLCs. Start with small projects like controlling a motor or traffic light. You can also automate simple processes such as mixing or filling.

Document every step with diagrams, flowcharts, and ladder logic drawings. Add features like alarms, timers, or safety interlocks as you progress. Small projects help build confidence and practical problem-solving skills.

Step 8: Move to Advanced Programming

After mastering Ladder Logic, explore other IEC 61131-3 languages. Function Block Diagram (FBD) uses graphical blocks for logic control. Structured Text (ST) is text based and resembles C or Pascal.

Learning multiple languages gives you flexibility for different projects. Modern PLCs allow hybrid programming, combining Ladder, FBD, and ST. This is useful when different parts of a system need different approaches.

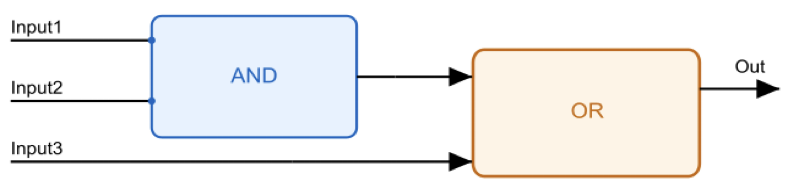

The subsequent figure exhibits a diagram showing a simple function block diagram.

It shows an AND block connected to an OR block. It also depicts that Inputs Input1 and Input2 feed the AND block, while Input3 feeds the OR block directly.

Step 9: Learn PLC Wiring

Programming alone is not enough. Physical connections are equally important. Learn how to wire digital and analog inputs and outputs correctly. Study diagrams showing connections to sensors, relays, and actuators.

Follow electrical safety standards, grounding rules, and proper procedures. Incorrect wiring can damage devices or create dangerous situations. Practice wiring carefully and double check connections.

Step 10: Study Advanced Topics

To become an expert, study industrial communication networks like Ethernet/IP, Profinet, and Modbus. These allow PLCs to exchange data with other devices and control systems.

Learn about Human-Machine Interfaces (HMIs) that display visual control panels. SCADA systems help monitor and control large scale industrial processes.

Also study safety PLCs, emergency stop systems, and Safety Integrity Levels (SIL). These skills increase your value and job opportunities in automation.

Step 11: Follow Best Practices

Good programming practices improve reliability and maintainability. Use clear, descriptive tag names and add comments in the code. Break large programs into reusable modules or routines.

Modular code simplifies debugging and future updates. Adopt standard naming conventions and document all changes. Consistency is essential, especially in team projects.

Step 12: Consider Online Courses and Certifications

Online courses help you progress faster. Platforms like SolisPLC, RealPars, Udemy, and Coursera provide guided lessons. Many include exercises, quizzes, and practical projects.

Some offer official certificates that demonstrate your competence to employers. Join professional communities and forums. Ask questions and share projects for feedback. Networking with experienced programmers is valuable for learning and career growth.

Step 13: Look for Jobs and Opportunities

PLC programmers are in high demand globally. Industries like manufacturing, automotive, oil and gas, and renewable energy rely on PLCs. Start with internships or entry-level technician roles.

Gain experience and gradually advance to automation engineer, control systems designer, or project manager.

Maintain a portfolio of completed projects to showcase your skills. Practical experience is key to success in this field.

Key Takeways: How to Learn PLC Controller Programming

This article detailed a structured approach to learning PLC programming. So, it depicted that in order to learn PLC program, start with the basics, then practice small projects to build confidence. Gradually progress to advanced topics and industry standards.

Consistent practice, curiosity, and patience are essential. PLC programming is more than a technical skill,it is a gateway to innovation. Each project you complete brings you closer to mastering industrial automation systems.

With dedication, you can achieve a rewarding career as a PLC programmer.

FAQ: How to Learn PLC Controller Programming

What is a PLC and what does it do?

A PLC (Programmable Logic Controller) is a ruggedized industrial computer used to control machines and processes automatically.

It reads input signals (from sensors/switches) and triggers outputs (to motors, lights, valves) based on a programmed logic.

Do I need an electrical background to learn PLC programming?

Not strictly, but having a basic understanding of electricity, wiring, and control systems gives you a big head start. Some training programs indicate a background in electrical devices helps.

How long will it take to learn PLC programming?

It varies. Many beginners can learn the basics within 36 months of dedicated study and practice. However, mastering advanced topics often takes 12 years or more handson experience.

Which PLC brand or platform should I start with?

Choose one brand/ platform and stick with it initially. Common ones include Siemens and AllenBradley (Rockwell). Once you understand fundamentals, transitioning to other brands is easier.

What programming language should I learn first?

Start with Ladder Logic ,it’s the most widely used and is intuitive, especially if you’re from an electrical background.

Later, you can learn other languages like Function Block Diagram (FBD) or Structured Text (ST) based on need.

Do I need physical hardware to practice PLC programming?

No. You can begin with simulation software which mimics real PLC behavior. This lets you write code, test logic, and learn safely before investing in hardware.

What are the main hardware components of a PLC system?

The key components are: CPU (Central Processing Unit) ,the “brain”; Power supply, provides energy; I/O modules, connect sensors and actuators. Note that, understanding these helps with wiring and troubleshooting.

Will certifications or online courses help?

Yes. Structured courses and certifications provide guided learning, credibility, and often access to simulation tools and instructor support. Many learners find them helpful.

What skills are employers looking for in a PLC programmer?

Employers often look for: Strong logic and problemsolving capability; Familiarity with at least one PLC platform/brand; Ability to read wiring diagrams and interface hardware and software; Best practices like clean code, modular structure, documentation

Is it worth learning PLC programming later in my career?

Absolutely. Many professionals from related fields (electronics, automation, control systems) upskill into PLC programming. It is widely in demand across manufacturing, energy, automotive, and other sectors.